Parallel operation axial flow primary fan automatic regulating method and device

An automatic adjustment and secondary fan technology, which is applied in the direction of machines/engines, mechanical equipment, non-variable pumps, etc., can solve the problems of affecting the combustion stability of the boiler, the operation status of the fan is not distinguished, and stalls, etc., to improve the automatic The effect of adjusting quality, actual inspection effect, and good economic benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

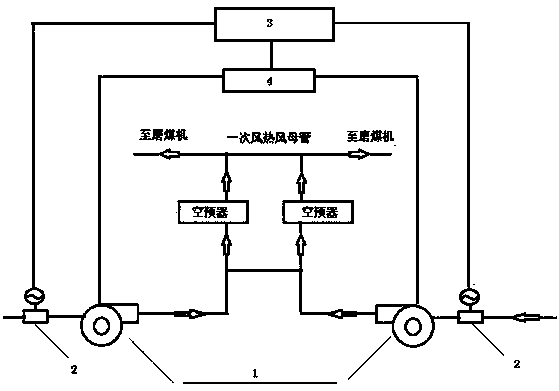

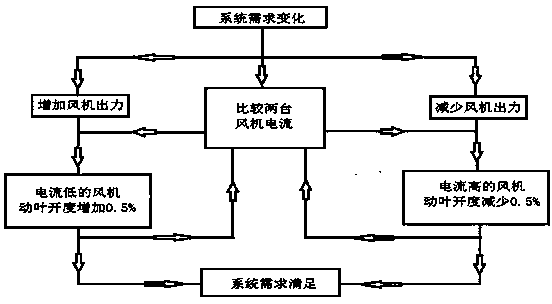

[0014] Examples such as figure 1 As shown, an automatic adjustment optimization method for axial-flow primary fans running in parallel is to add a fan current monitoring and comparison function module to the automatic control module of the fan blades, and first judge the flow rate of two or more fans when automatically adjusting the air volume of the fans. The adjustment order of the fan air volume is determined according to the current of the fan; the adjustment condition for increasing the air volume is to increase the rotor blade opening of the fan with low current first; the adjustment condition for reducing the air volume is to reduce the rotor blade opening of the fan with high current first .

[0015] When the axial-flow primary fans running in parallel in existing thermal power plants operate in the automatic control mode, the air volume adjustment is controlled by the automatic control module of the fan rotor blades, and the automatic control module of the fan rotor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com