A flow equalizing distributor used in the tube box of a dry shell-and-tube evaporator

An evaporator tube box and shell-and-tube technology, applied in evaporator/condenser, refrigeration components, refrigerators, etc., can solve the complex process of liquid homogenization plate and capillary tube, can not completely solve the uniform distribution, and affect the energy efficiency of refrigeration system. ratio and other issues, to achieve the effect of facilitating welding or screw fixing, improving efficiency, and improving energy efficiency ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions of the present invention will be described in detail below, but the protection scope of the present invention is not limited to the embodiments.

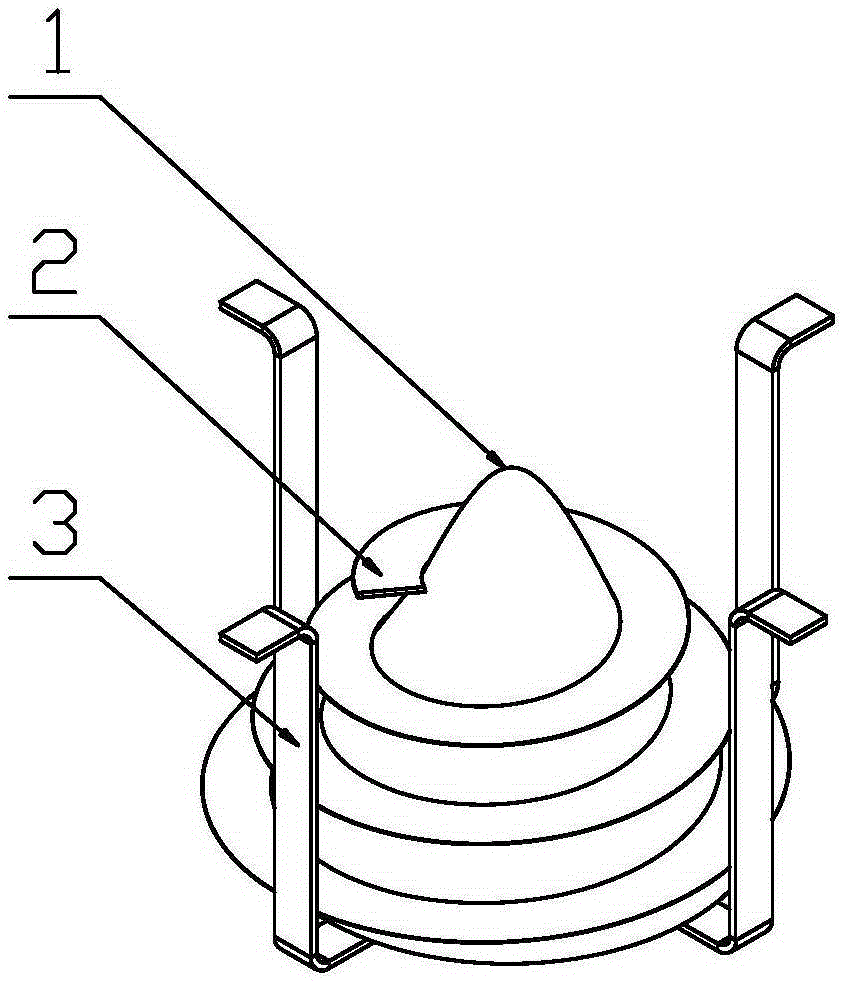

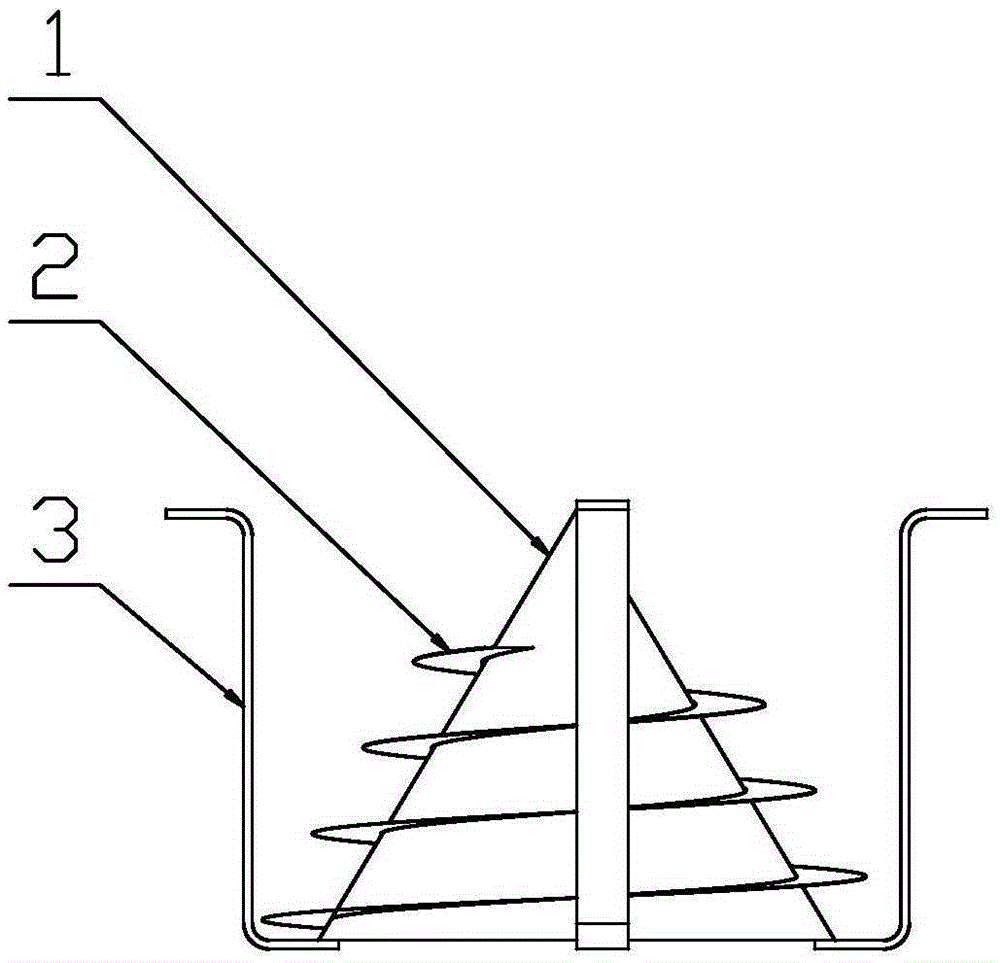

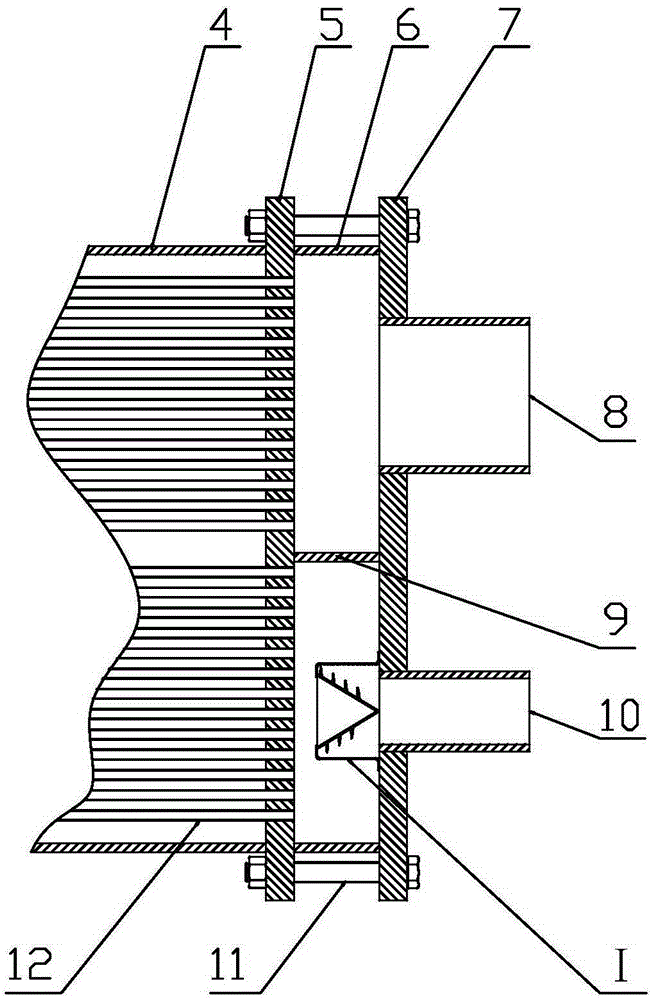

[0018] Example: The current equalizing distributor used in the tube box of the dry shell-and-tube evaporator according to the present invention, such as figure 1 , figure 2 As shown, it includes a cone body 1, a spiral piece 2 and a leg 3; the spiral piece 2 is fixed on the outside of the cone surface of the cone body 1, and is spirally arranged from the bottom of the cone body 1 to the top, as image 3 As shown, there are four legs 3, which are evenly distributed around the cone body 1. One end of the leg 3 is connected to the bottom circumference of the cone body 1, and the other end is connected to the circumference of the refrigerant inlet on the end cover of the evaporator; the cone body 1 The height is less than the thickness of the evaporator tube box 6, and the diameter of the bottom circle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com