Flexible capacitive touch sensor and manufacturing method of flexible capacitive unit of flexible capacitive touch sensor

A tactile sensor, flexible capacitor technology, applied in multilayer capacitors, thin-film/thick-film capacitors, instruments, etc., can solve problems such as the difference error of the elastic modulus of electrodes and dielectrics, not realizing full flexibility, etc., and achieve the effect of reducing the difficulty of solving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

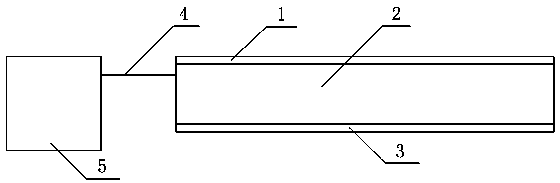

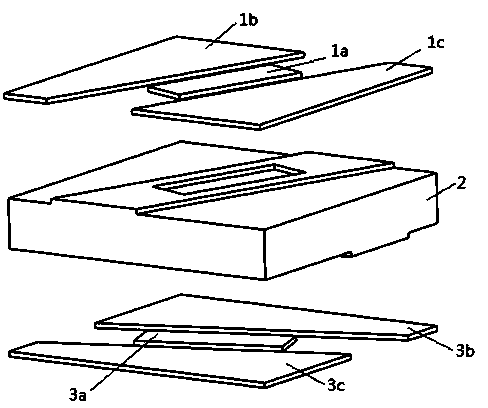

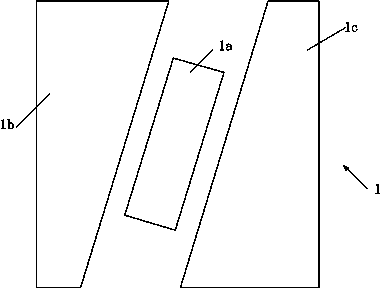

[0026] A flexible capacitive touch sensor, comprising a flexible capacitor unit and a signal processing circuit board 5 electrically connected to it, the flexible capacitor unit is composed of a flexible insulating medium layer 2 located in the middle layer, and respectively located on the upper and lower surfaces thereof The conductive capacitor plate layer 1 and the lower conductive capacitor plate layer 3 are composed, and the upper and lower surfaces of the flexible insulating medium layer 2 are respectively provided with concave holes that match the shapes of the upper conductive capacitor plate layer 1 and the lower conductive capacitor plate layer 3. groove, the upper conductive capacitor plate layer 1 is embedded in the groove provided on the upper surface of the flexible insulating medium layer 2, and the lower conductive capacitor plate layer 3 is embedded in the groove provided on the lower surface of the flexible insulating medium layer 2, such as figure 1 , 2 As s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com