Wire Rope Tensile Testing Machine Fixtures

A tensile testing machine, wire rope technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve problems such as no good solutions, and achieve the goal of increasing the grip area and length, improving the life of the fixture, and reducing the compression damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

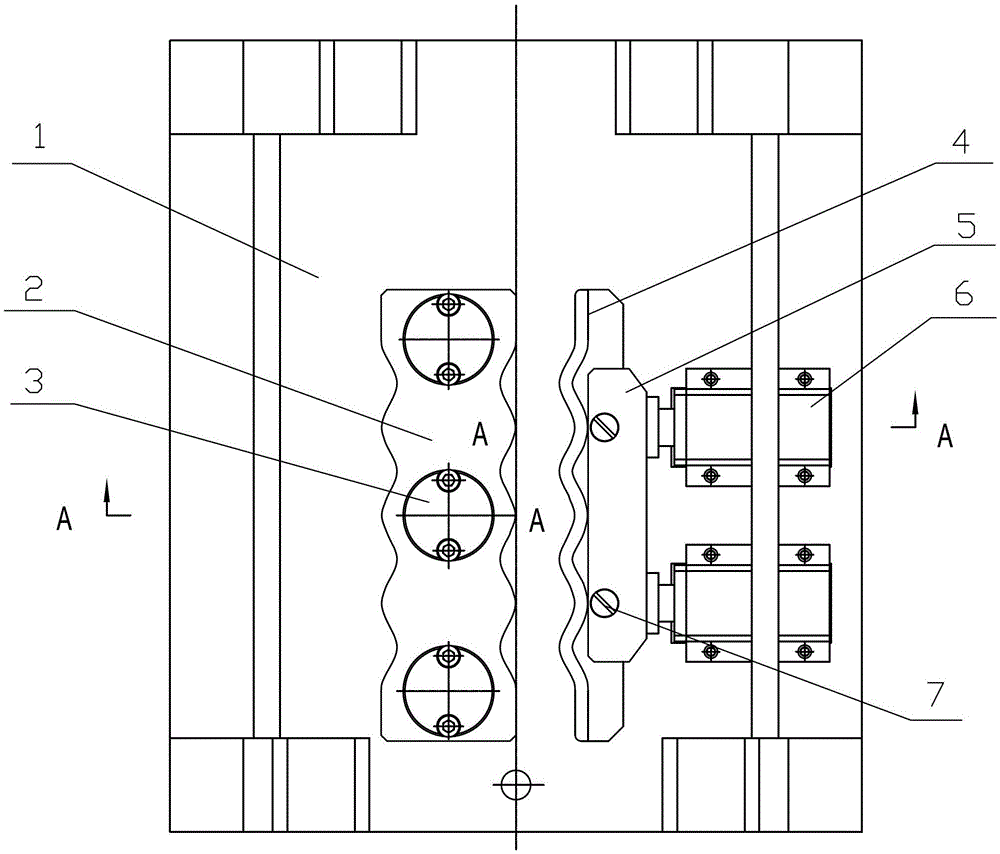

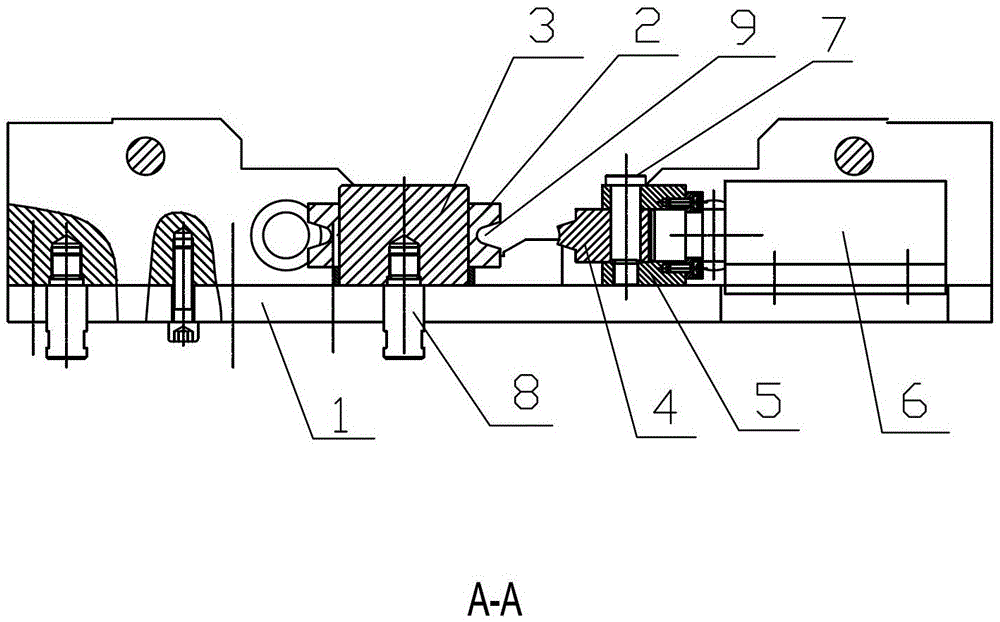

[0016] Refer to the attached figure 1 And attached figure 2 The jig of the steel wire rope tensile testing machine of the present invention will be described in detail below.

[0017] The fixture of the steel wire rope tensile testing machine of the present invention has a structure comprising an S-shaped fixture. The S-shaped fixture includes a fixed fixture 2 and a moving fixture 4. The section of the fixed fixture 2 is V-shaped and grooved on both sides. The fixed fixture 2 is fixed on the bottom plate 1; the cross-section of the movable fixture 4 is generally convex, and the pressing surface is shallow concave, which is convenient for pushing the wire rope into the fixed fixture 2 and fully gripping it. The movable fixture 4 and the fixed fixture 2 After being combined, a round tube S-shaped bending clamping space is formed, the moving fixture 4 is connected to the moving fixture seat 5, and the moving fixture seat 5 is connected to the horizontal push cylinder 6, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com