Nitrogen content measurement method of ultra-thin gate silicon oxynitride film

A technology of silicon oxynitride and measurement method, which is applied in the field of semiconductors, can solve the problems of high cost, damage, and long detection time, and achieve the effects of intuitive detection structure, shortened detection time, and saved detection cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

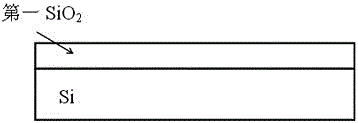

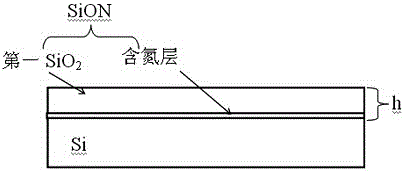

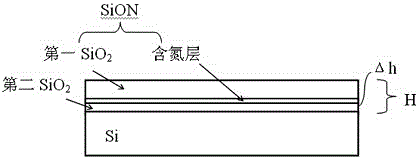

[0024] Through the method of the invention, the nitrogen content in the ultra-thin gate silicon oxynitride film can be measured. Before applying this measurement method, it is generally through conventional processes, such as figure 1 As shown, first, a layer of ultra-thin gate oxide (Ultra-thin Gate Oxide) film (hereinafter also referred to as the first SiO 2 layer); such as figure 2 shown, then enters the nitriding process, for example using N 2 O / NO nitrogen source gas is annealed, so that the Si layer and the first SiO 2 Nitrogen atoms are introduced at the interface of the layer to bond with silicon atoms to form a nitrogen-containing layer. The general semiconductor industry regards nitrogen-containing SiO 2 Commonly known as SiON, therefore, the first SiO formed at the gate position of the silicon substrate according to the above-mentioned several processes 2 layer and the nitrogen-containing layer constitute an ultra-thin gate silicon oxynitride (Ultra-thin Gate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com