A detection method of the aluminum spray layer on the edge of the target

A detection method and target material technology, applied in metal material coating process, coating, analysis materials, etc., can solve the problem of inability to accurately and effectively monitor the quality of aluminum sputtering layer, light, personnel, angle uncertainty, coating Incomplete detection and other problems, to achieve the effect of objective detection method, intuitive detection structure and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

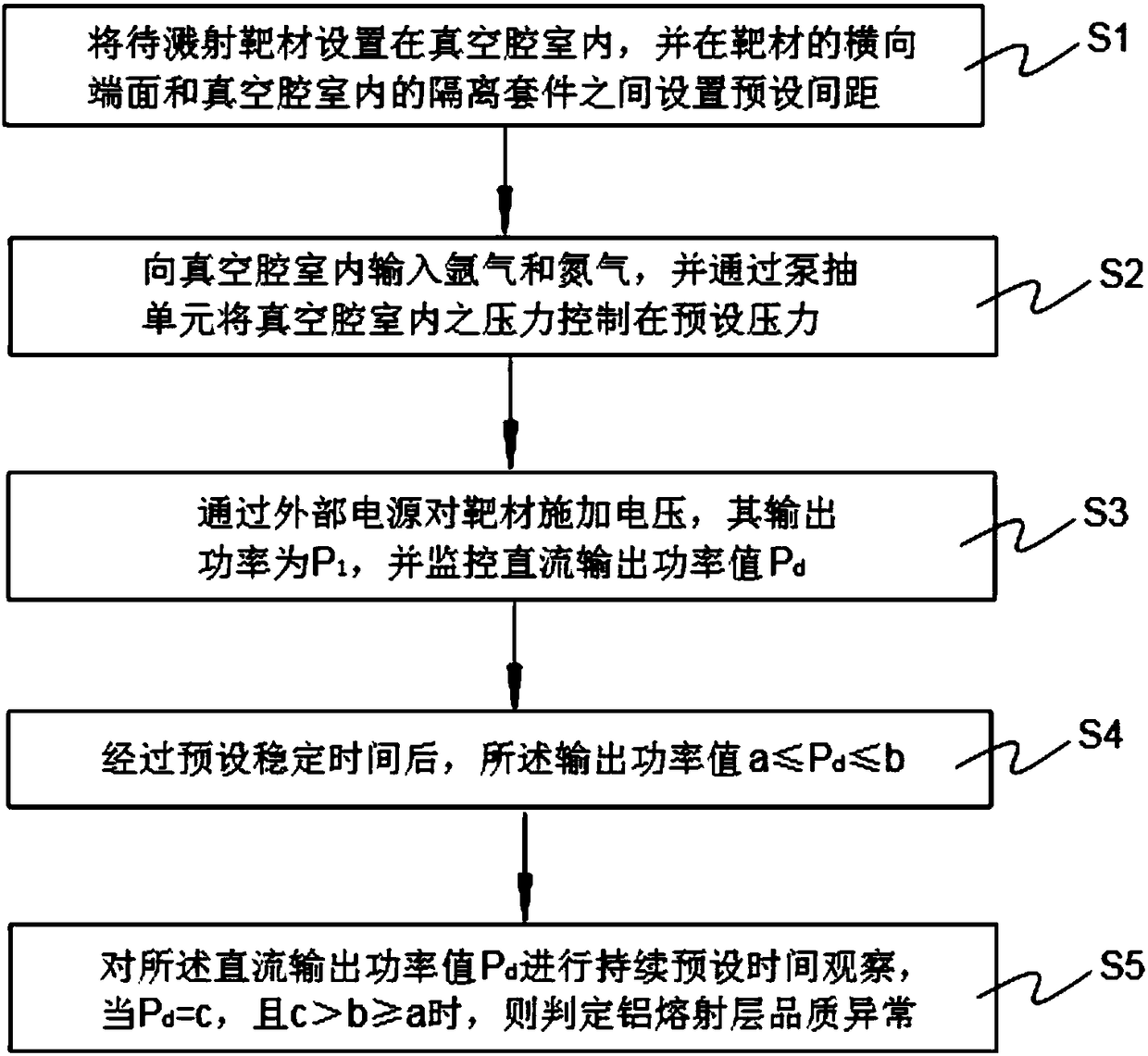

Method used

Image

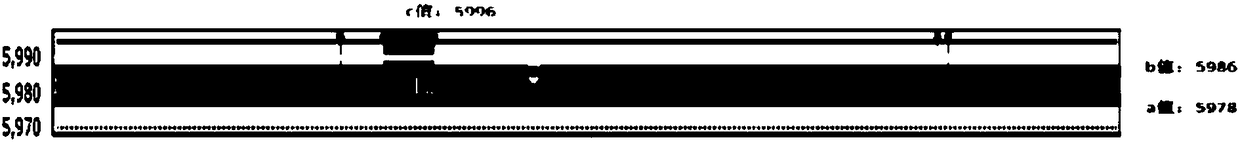

Examples

Embodiment Construction

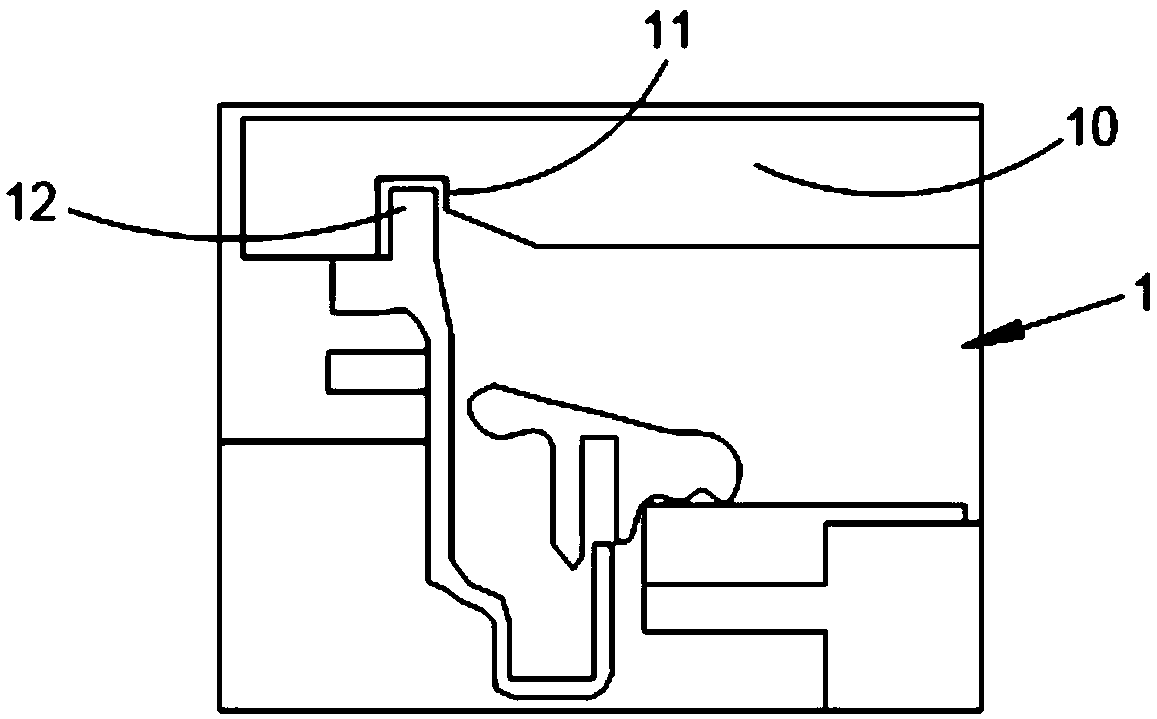

[0025] In order to illustrate the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

[0026] In the physical vapor deposition system, the target, as an important component, is widely used in the field of integrated circuit manufacturing. In order to prevent particle defects caused by the peeling of the reverse deposition film (Re-deposition Film) on the edge of the target during the process, it is usually necessary to spray an aluminum spray layer on the edge of the target to increase the roughness of the target, thereby increasing the reverse deposition film. Absorbency prevents peeling. However, when the quality of the aluminum sprayed layer on the edge of the target is abnormal, a discharge phenomenon will be formed, resulting in the peeling off of a large number of reverse deposited films and spherical arc defects.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com