Separating device for separating magnetic or magnetizable particles present in a suspension

A separation equipment and magnetization technology, which is applied in the direction of magnetic separation, solid separation, high-gradient magnetic separator, etc., can solve the problem that particles cannot be separated, and achieve the effect of small current demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

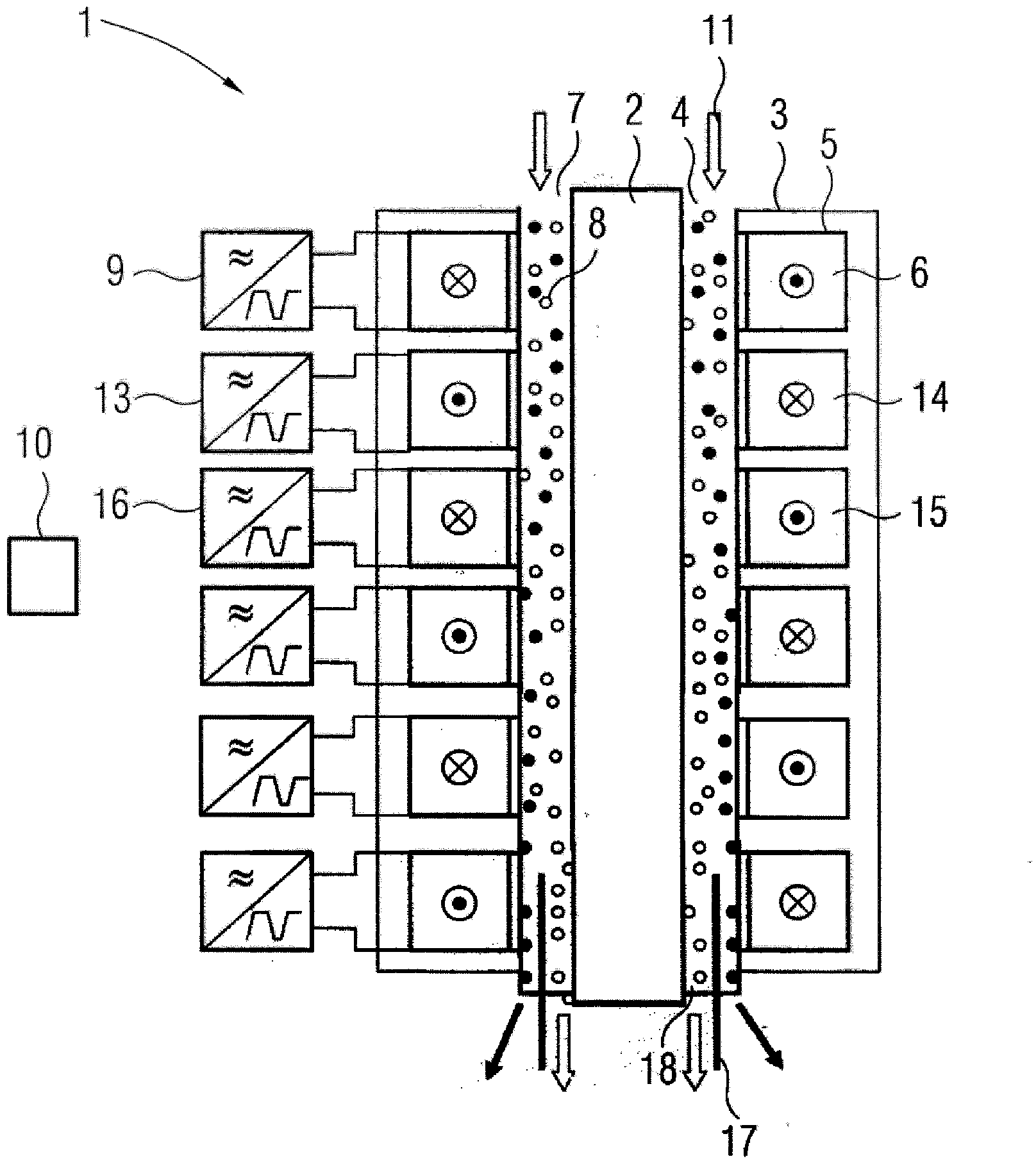

[0020] figure 1 The shown separating device 1 comprises a cylindrical extrusion body 2 which is spaced apart from and surrounded by a concentric cylindrical iron yoke 3 . An annular separation channel 4 is formed between the extrusion body 2 and the yoke 3 . The ferrous yoke has a circumferential groove 5 in which a coil 6 is arranged. The separating channel 4 and the coil 6 are separated from each other by a separating wall, not shown in detail, so that liquid flowing through the separating channel 4 does not come into contact with the coil 6 . In the exemplary embodiment shown, six coils are shown, however, this is only schematically to facilitate understanding, and the number of coils arranged one behind the other in the direction of flow can be selected arbitrarily.

[0021] The inlet 7 of the separation channel 4 is continuously supplied with suspension 8 via a supply device designed as a pump. The suspension 8 contains magnetizable and non-magnetizable constituents, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com