Method for machining a workpiece, tool head for a lathe, and lathe

A technology for machining tools and cutter heads, used in metal processing, metal processing equipment, tool holders, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

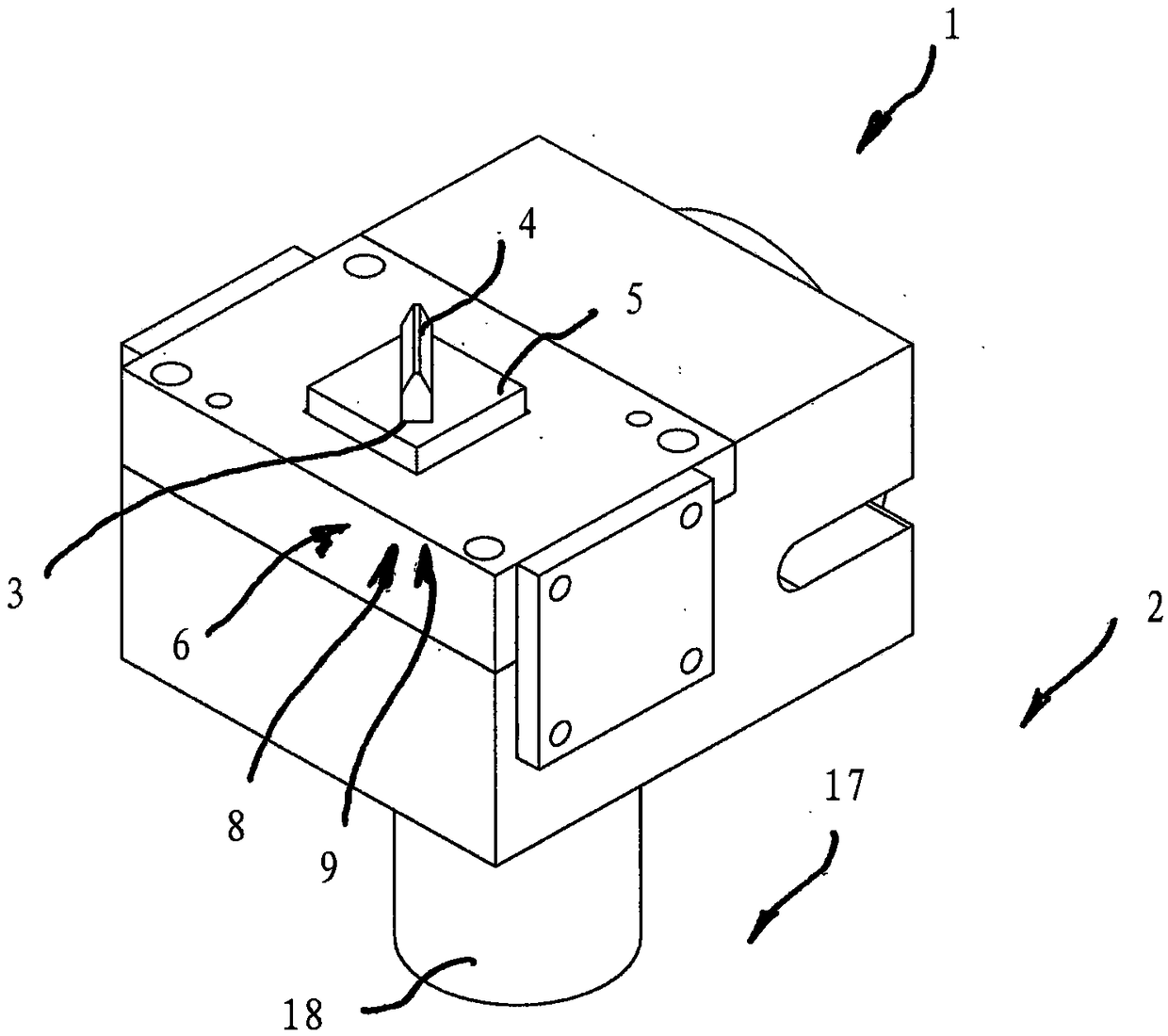

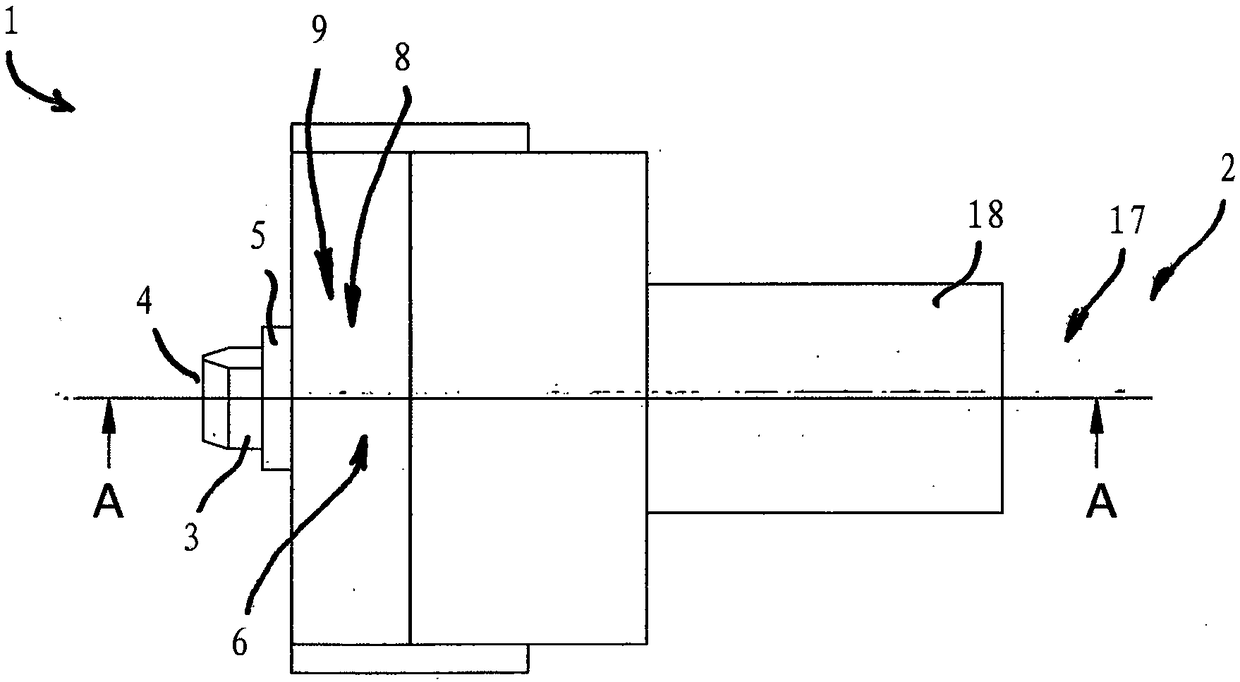

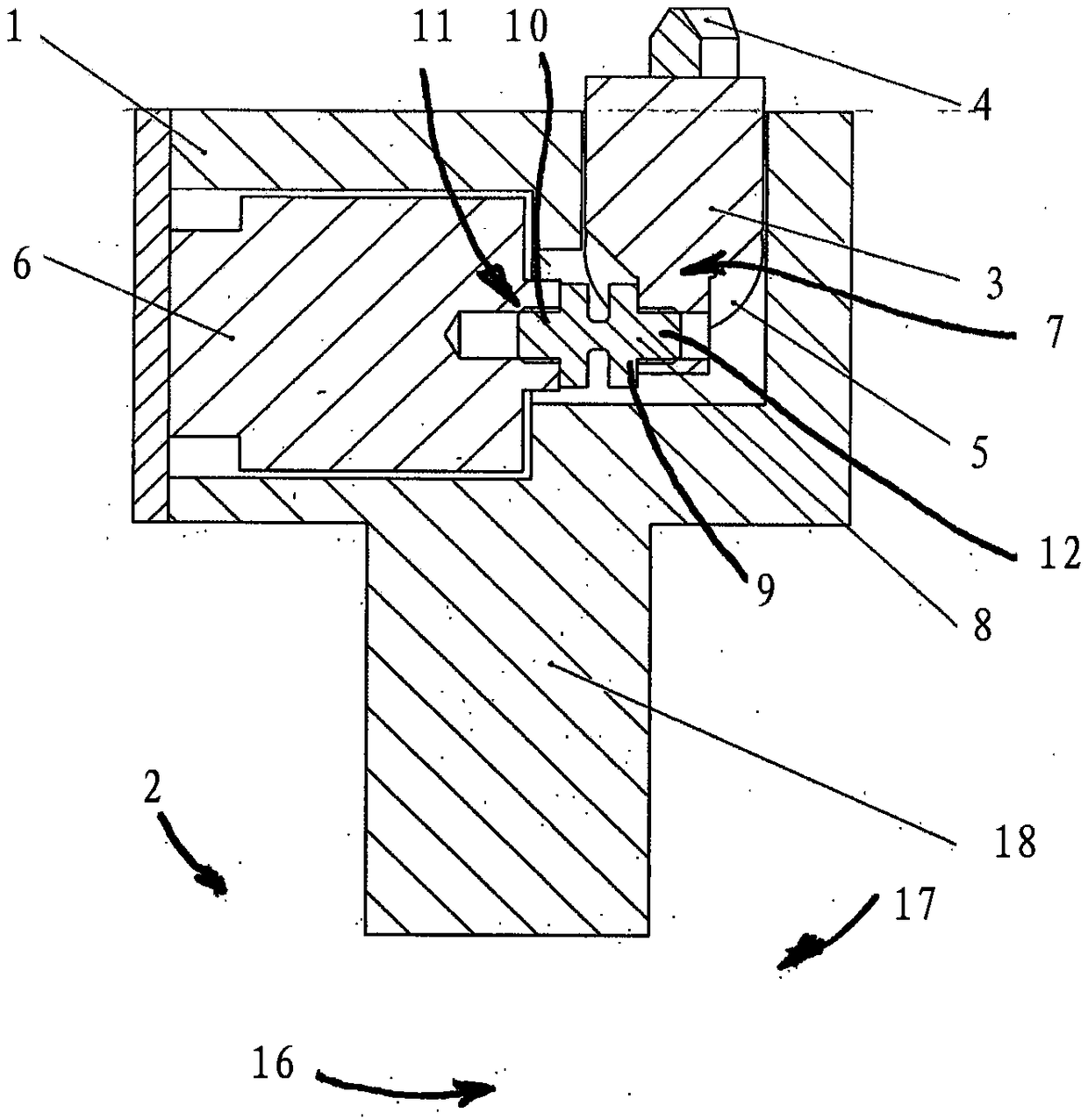

[0046] The overall figures show a cutter head generally indicated at 1 for a lathe 2 which is only largely schematically positioned at Figure 4 shown in . The cutter head 1 is provided with a machining tool 3 having a cutting portion 4 . The machining tool 3 is held by the tool holder 5 of the cutter head 1 . The cutterhead 1 has an actuator 6 which is designed to generate a movement, more precisely an additional movement, in the form of an oscillating pivoting movement of the tool holder 5 about a pivot axis 7 .

[0047] according to image 3 It can be seen that the actuator 6 is configured for generating an oscillating linear reciprocating movement and that the cutter head 1 has means 8 for converting said oscillating linear reciprocating movement into an oscillating pivoting movement of the knife holder 5 . according to image 3 and 4 , the actuator 6 for generating the oscillating linear reciprocating motion is arranged such that the oscillating linear reciprocating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com