Coating for a rotating plate

A feeder and turntable technology, which is applied in the direction of thin material handling, delivery of filamentous materials, transportation and packaging, etc., to achieve the effects of simplifying the manufacturing process, fast manufacturing, and saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

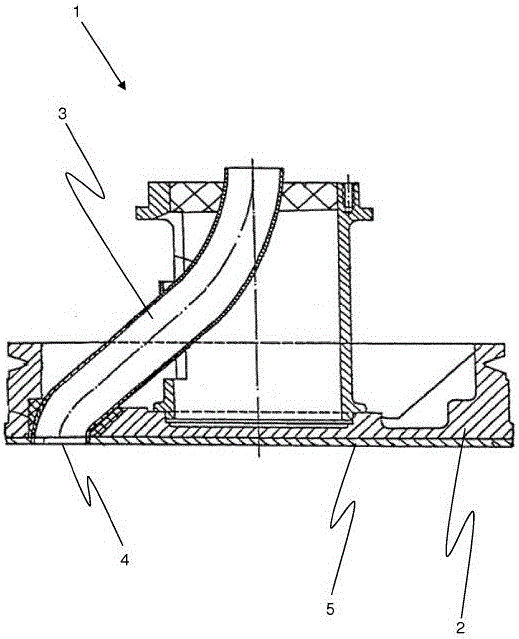

[0036] exist figure 1The schematic structure of the carousel feeder 1 is shown in . The carousel feeder 1 here consists of a base body 2 and a fiber web channel 3 arranged in the base body 2 . A fiber ribbon (not shown here) is drawn through this fiber ribbon channel 3 and leaves the carousel feeder 1 downwards through the fiber ribbon channel 3 and the opening 4 of the base body 2 . The cover 5 is attached to the base body 2 on the underside of the carousel 1 and likewise has an opening 4 . In the intended use of the carousel feeder 1 , the lower side is the side facing the cans. A coating 6 is applied to the lower surface or underside of the cover 5 , which coating is illustrated in detail in FIG. 2 .

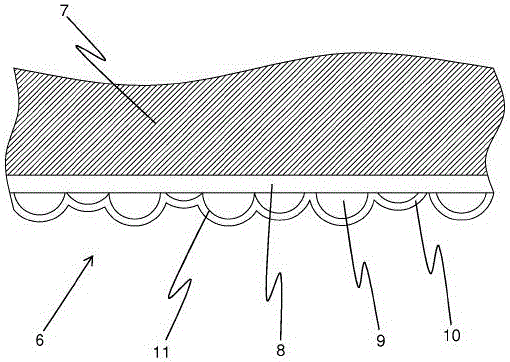

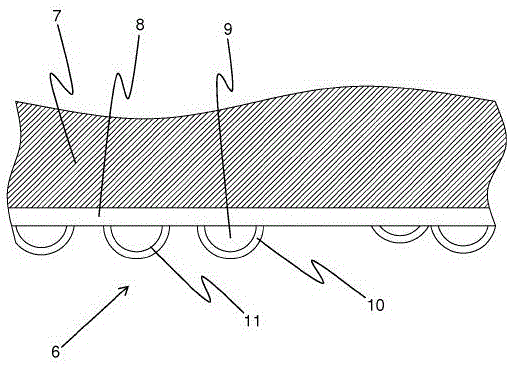

[0037] Figure 2a A cross-section of a coating 6 is shown with spherical, irregular protrusions 11 . The coating 6 is applied to the primer 7 . The primer 7 can be part of the cover 5 or part of the base body 2 . This coating 6 has three individual layers, namely a bas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com