Electrically conductive pin connection

A conductive and conductive contact technology, applied in the direction of conductive connection, circuit, connection, etc., can solve the problems affecting the reliability and quality of conductive screw-in connection, increase the resistance value, etc., and achieve the cost reduction of testing and repair. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

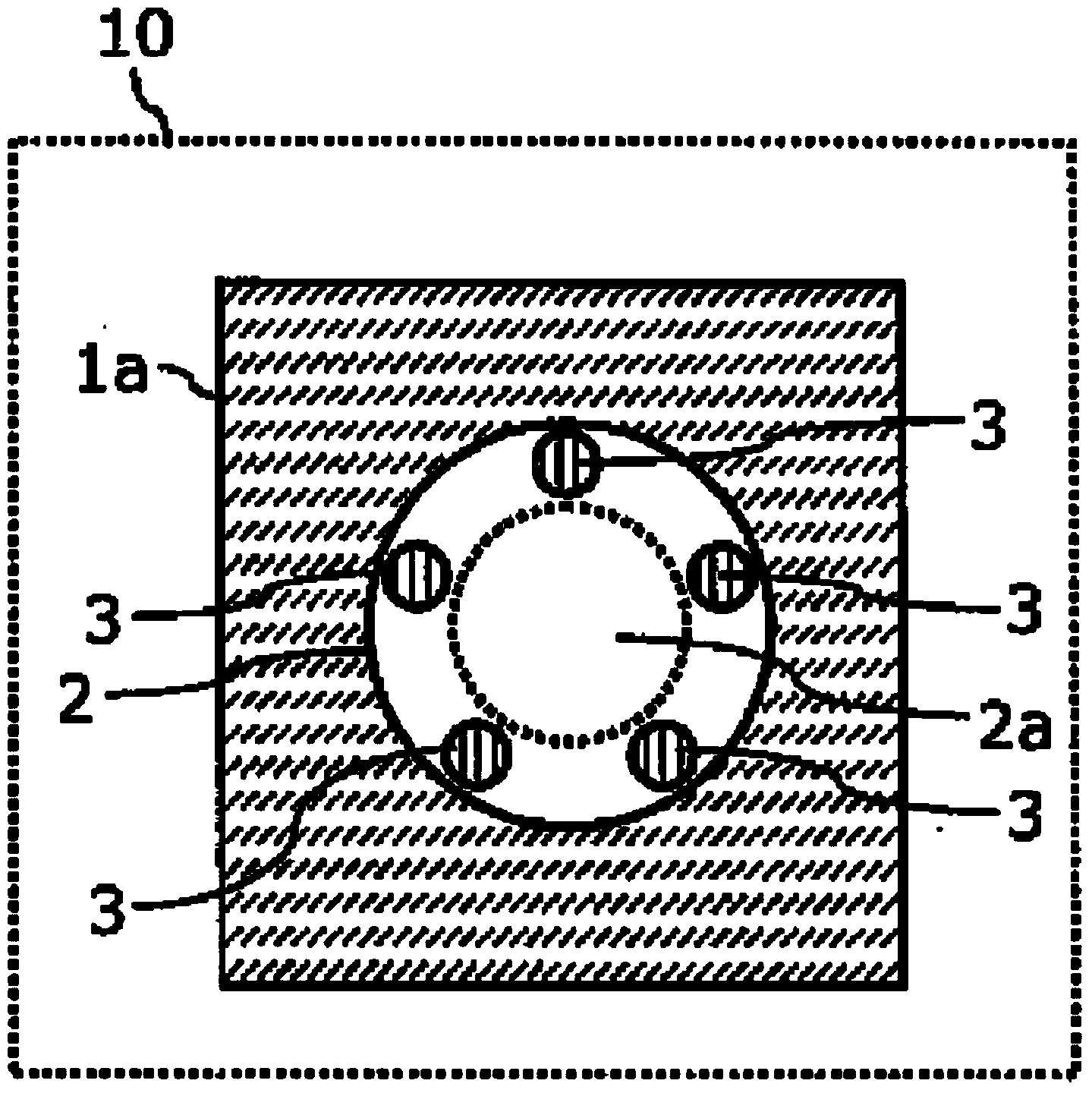

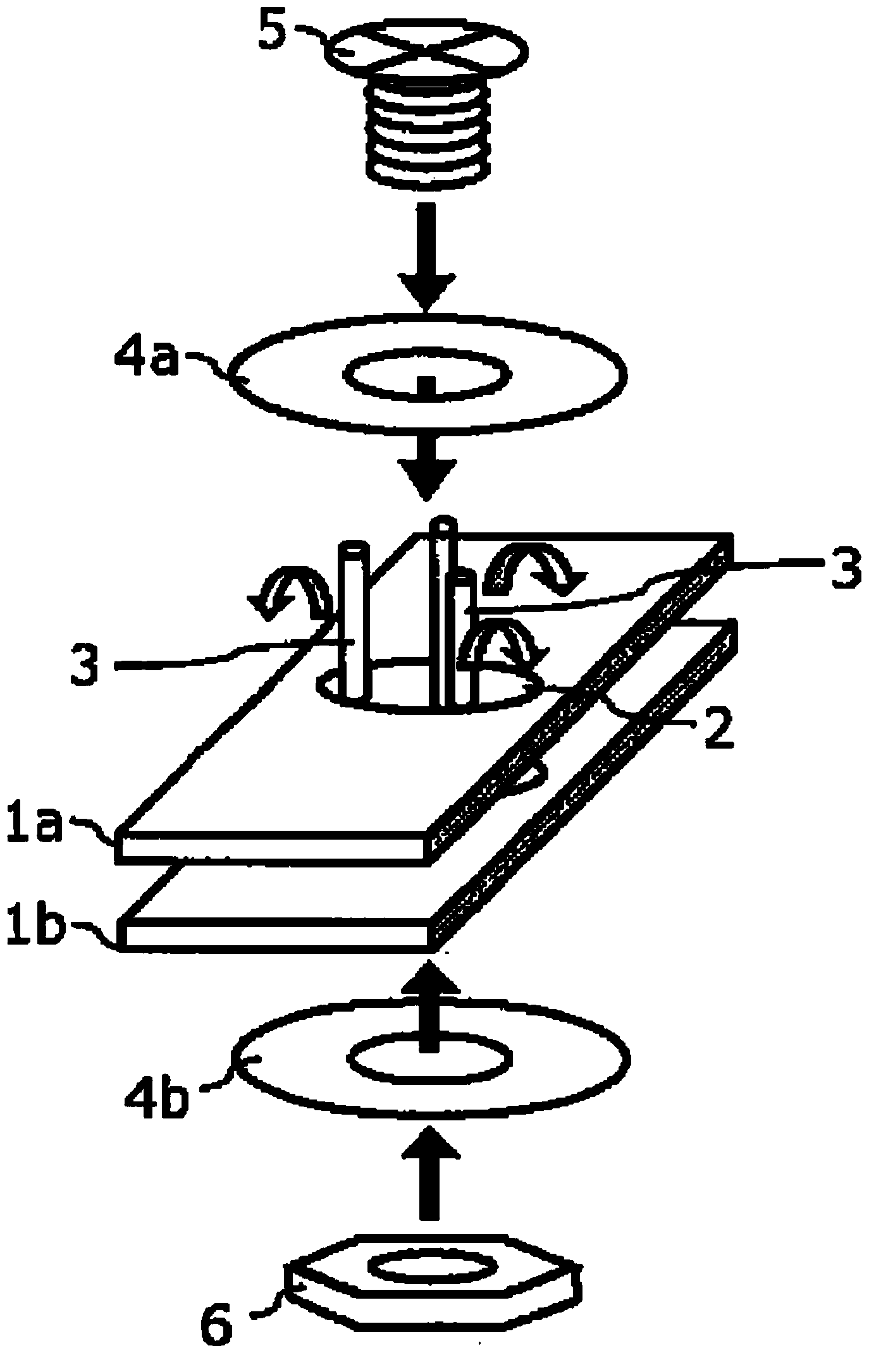

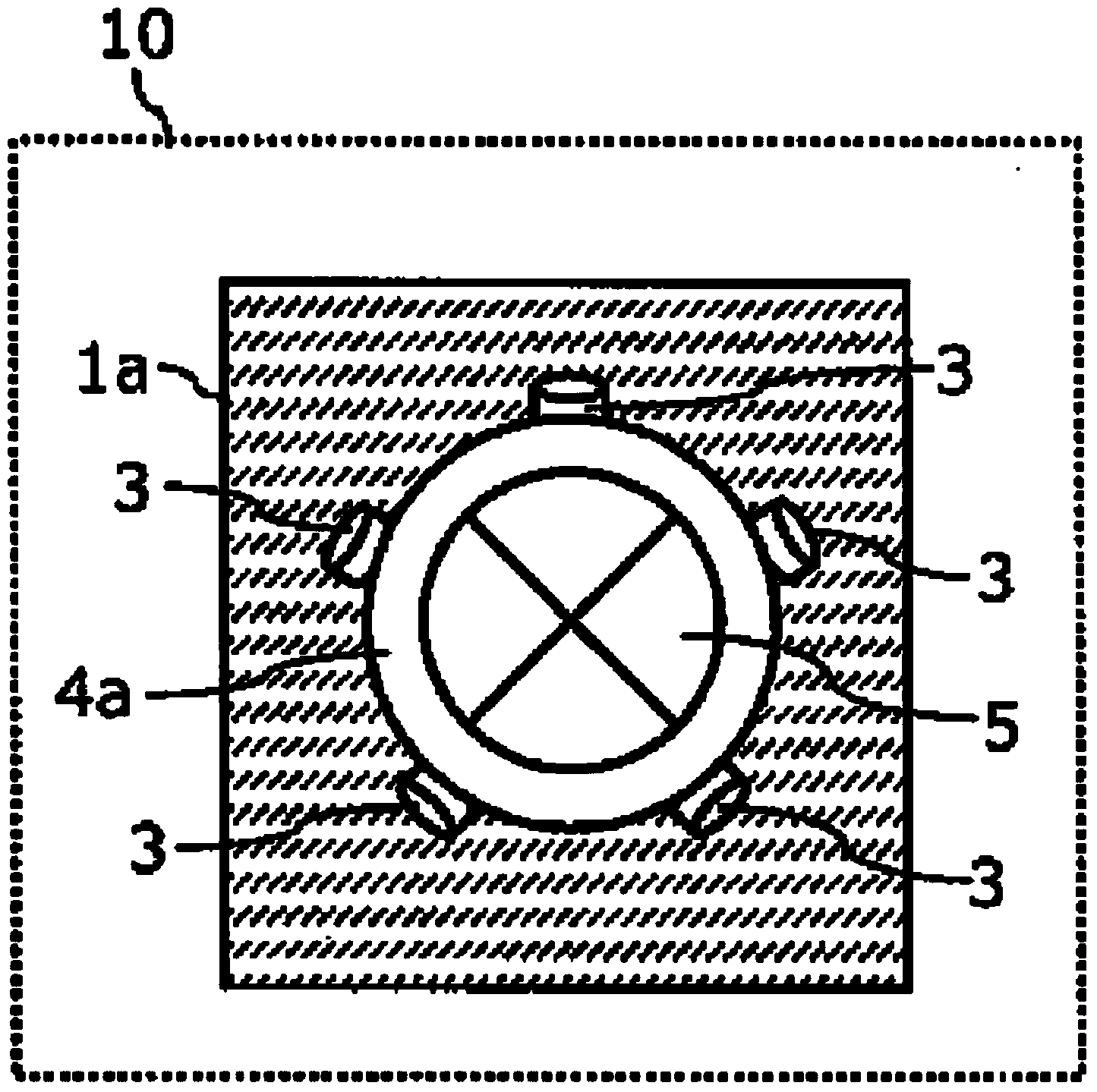

[0031] Contact members in the context of the present invention include all possible elements which are in mechanical contact with each other and which are connected to each other by means of a mechanical connection. In particular, the contact member may comprise a metal sheet, a housing part, a wire, a wire strand, a pole piece, a contact piece, a contact strip or similar elements. The contact member in the context of this invention may in particular be electrically conductive and in this respect may be made of an electrically conductive material, for example a metal, such as a non-ferrous metal, such as copper, aluminum, nickel, tin or Non-ferrous alloys such as precious metals such as gold, silver, platinum, palladium or similar alloys, organics or carbon fiber composites.

[0032] Connecting pins in the context of this invention may include all possible connecting elements comprising a connecting body connected between at least 2 contact members extending through suitable g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com