Active handling apparatus and method for contact tasks

A technology of operating device and contact force, applied in the direction of joints, instruments, manipulators, etc., can solve problems such as the increase of contact force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

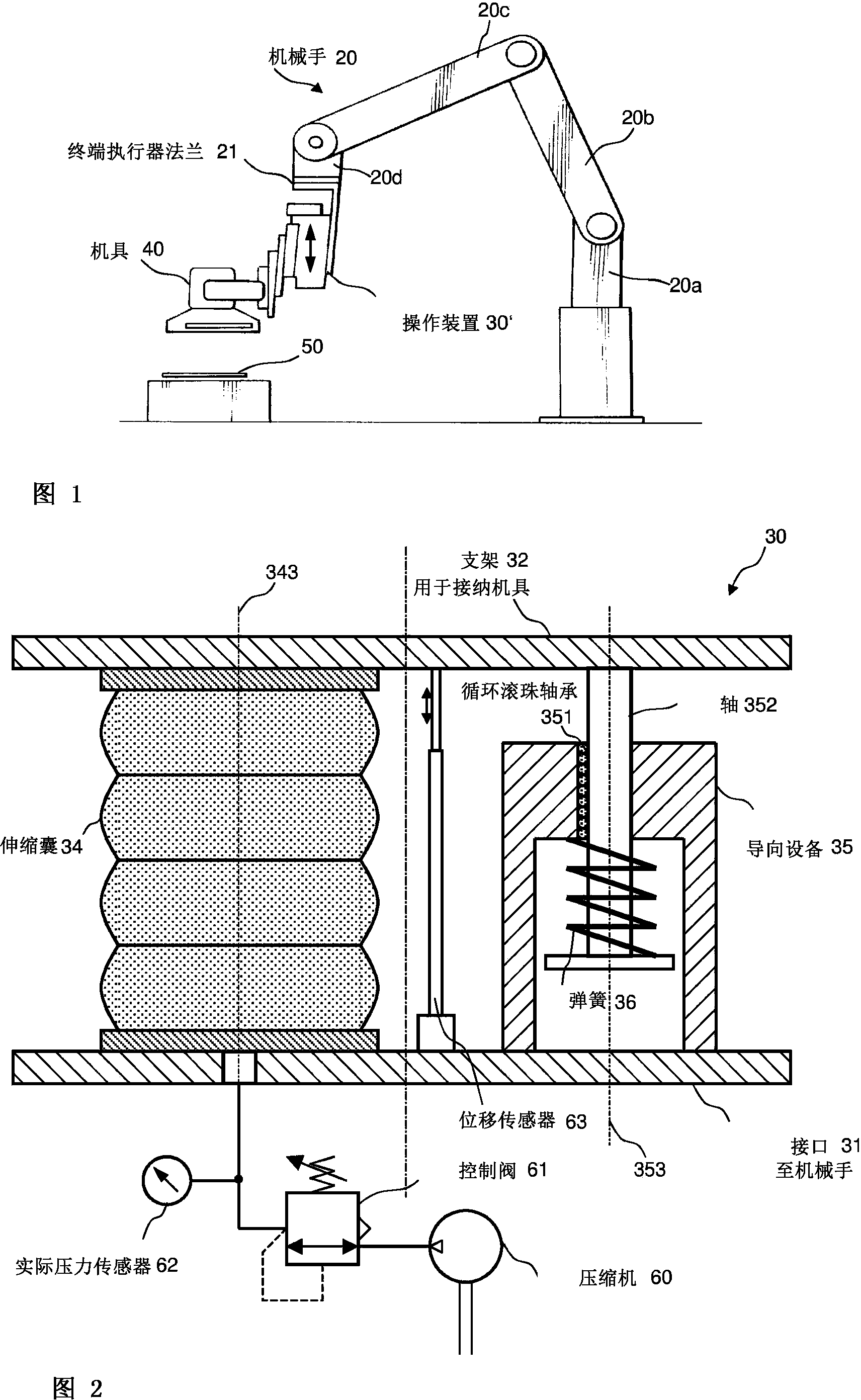

[0022] As an embodiment of the present invention, figure 1 Shown is a robot-assisted automatic grinding plant with an industrial robot as manipulator 20, a grinder 40 as implement and a handling device 30' arranged on the end effector flange 21 of the manipulator 20 Between the tool 40 and the tool 40 , it is mainly used for precision control or precise adjustment of the movement of the tool 40 relative to the workpiece 50 to be processed and to adjust the force exerted by the tool 40 on the workpiece 50 to be processed. The structure of the manipulator 20 has the following secondary functions. This embodiment uses a standard industrial robot with four arm segments 20a, 20b, 20c and 20d. The function of the manipulator is mainly to position the tool 40 on or above the surface of the workpiece 50 to be processed in the operating position. The present invention performs precise positioning adjustment, especially precise active force adjustment, through the operating device 30'...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com