Pesticide spraying device of sprayer

A sprayer and spray head technology, which is applied to the device, application, animal husbandry and other directions of catching or killing insects, can solve the problems of low work efficiency, small spraying range, manual swinging of the nozzle, etc., and achieves improved work efficiency and simple structure. , The effect of spraying evenly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

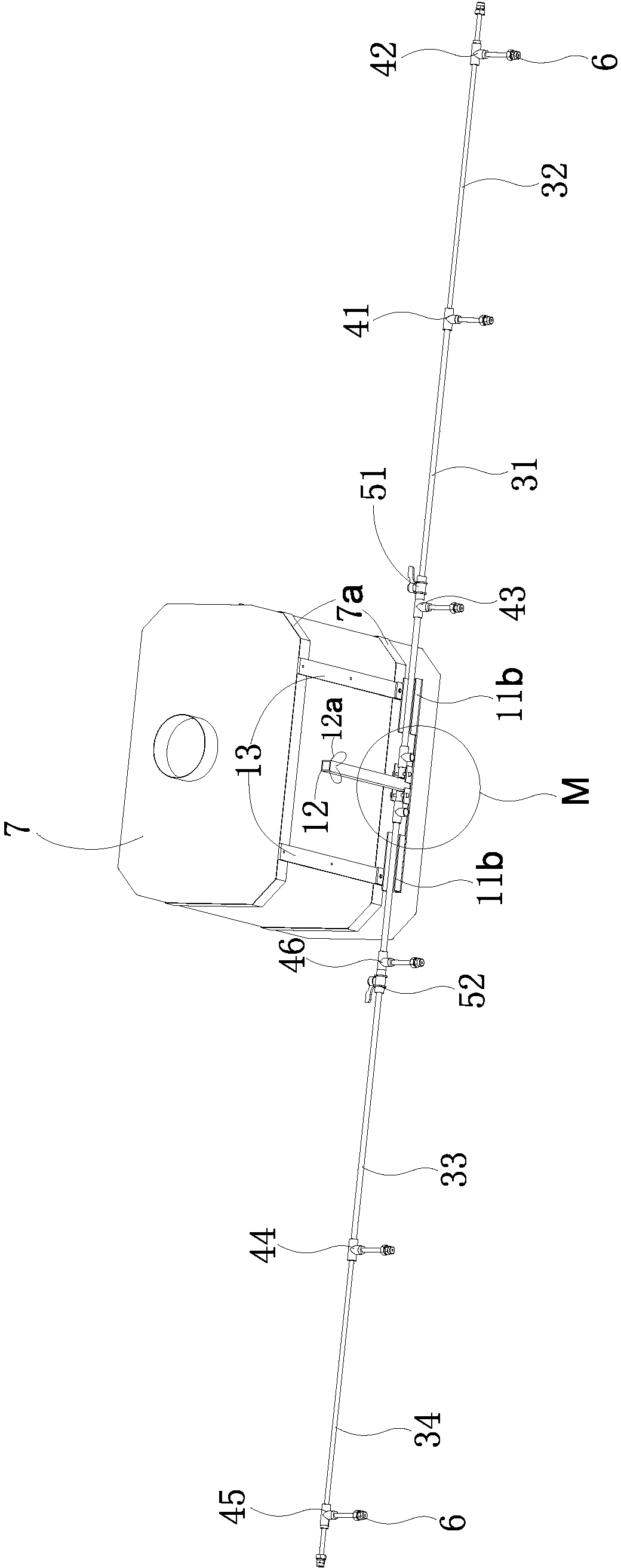

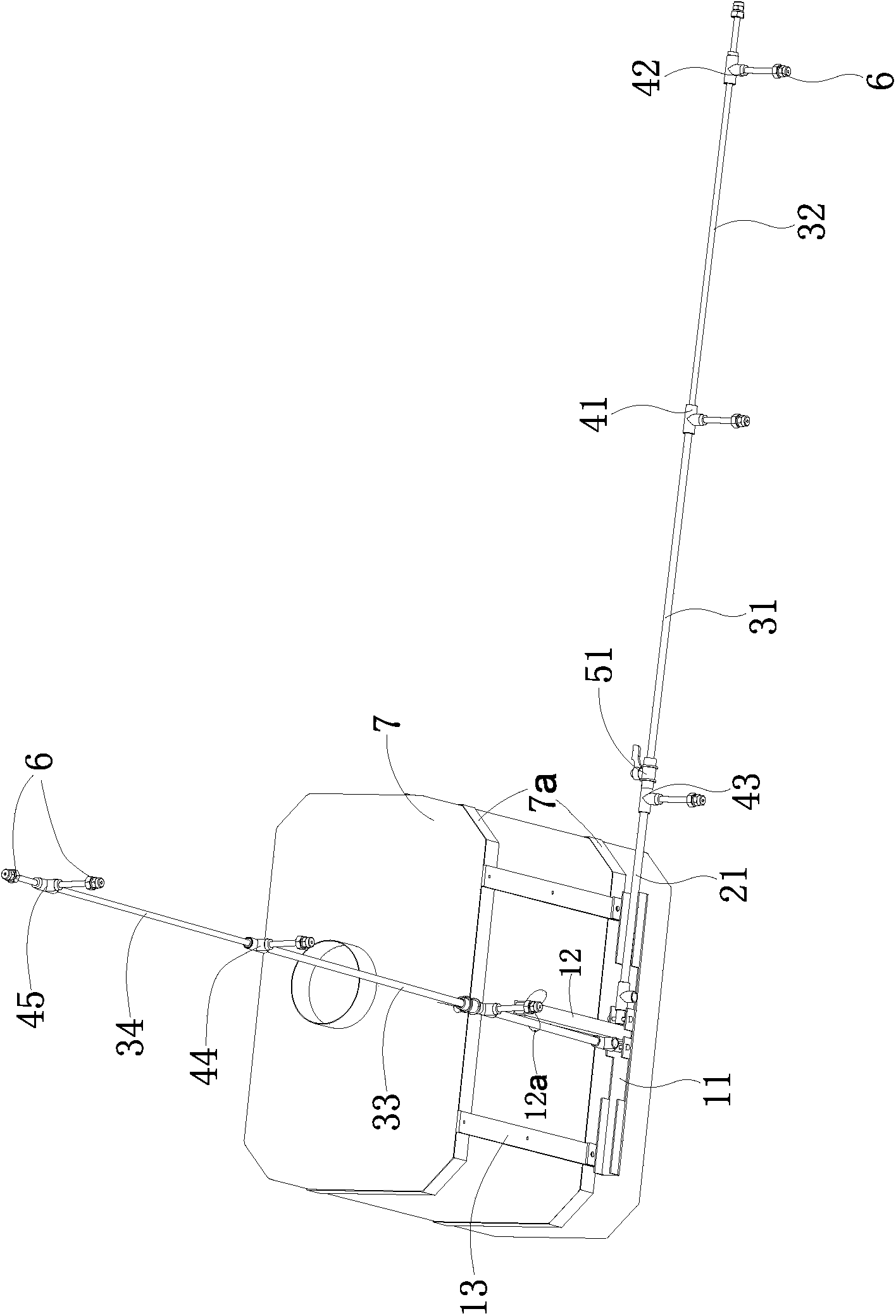

[0019] Such as figure 1 and 2 Shown:

[0020] The device includes a support, two connecting pipes, four extension pipes and eight nozzles 6 .

[0021] The bracket includes a cross bar 11 and a vertical bar 12, the vertical bar 12 is welded on the upper middle part of the cross bar 11, and the upper end of the vertical bar 12 is fixed with two fixed ropes 12a;

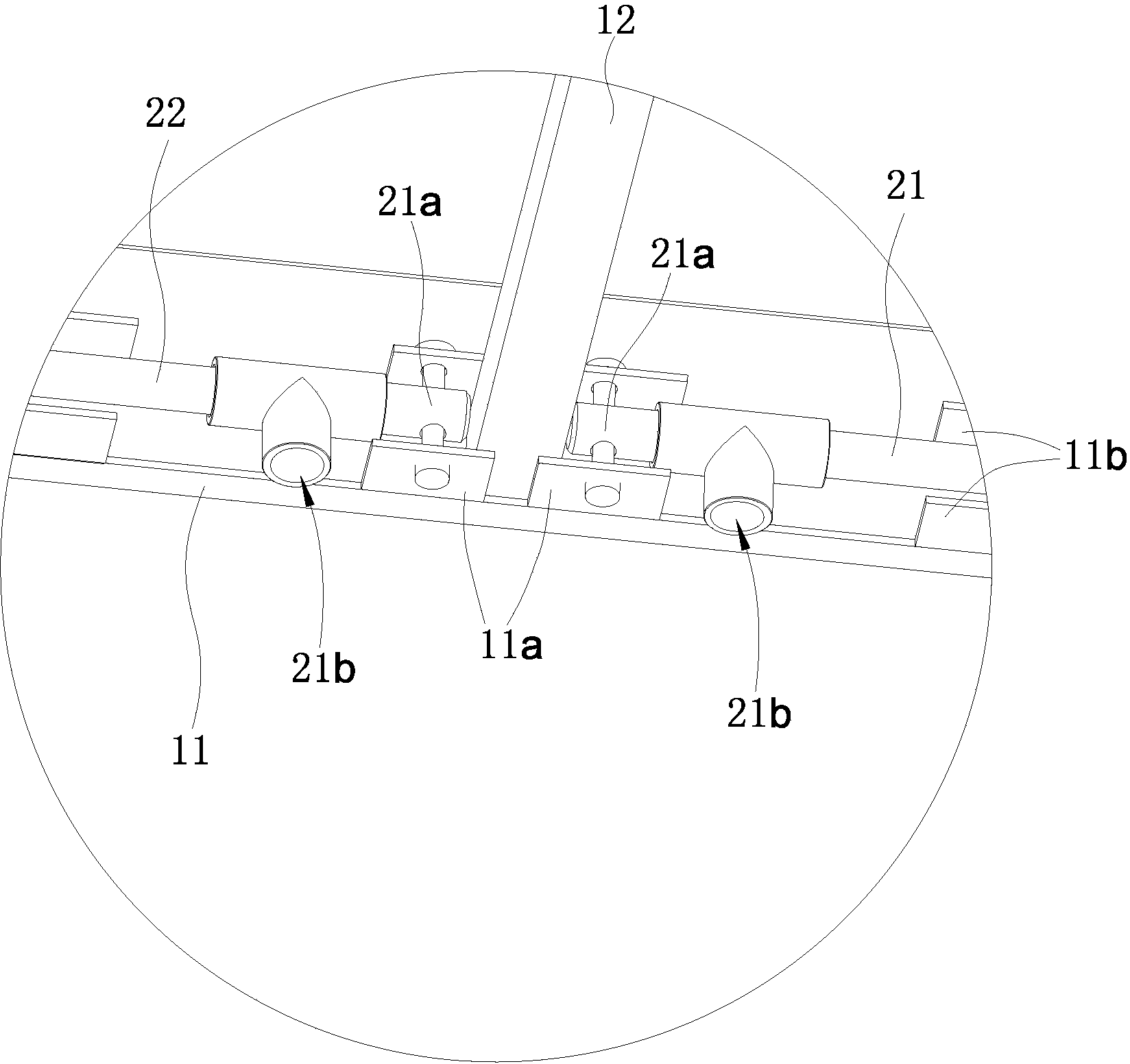

[0022] Two hinge seats are placed on the upper part of the cross bar 11, and the two hinge seats are respectively distributed on both sides of the vertical bar 12. Each hinge seat includes two parallel hinge plates 11a, and the two hinge plates 11a are welded on the cross bar 11. , there is a gap between the two hinged plates 11a, and the trend of the gap is consistent with the axial direction of the cross bar 11; a limit seat is respectively placed on the upper parts of the two ends of the cross bar 11, and each limit seat includes two parallel welding The direction of the gap between the two limiting pieces 11b is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com