One-step injection-molded smoke filter

A filter device and injection molding technology, applied in the direction of e-liquid filter, tobacco, application, etc., can solve the problems of flue gas loss, strong air suction, failure to achieve the desired effect of the inventor, etc., to change the flow state of flue gas, The effect of increasing the flow velocity of the flue gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

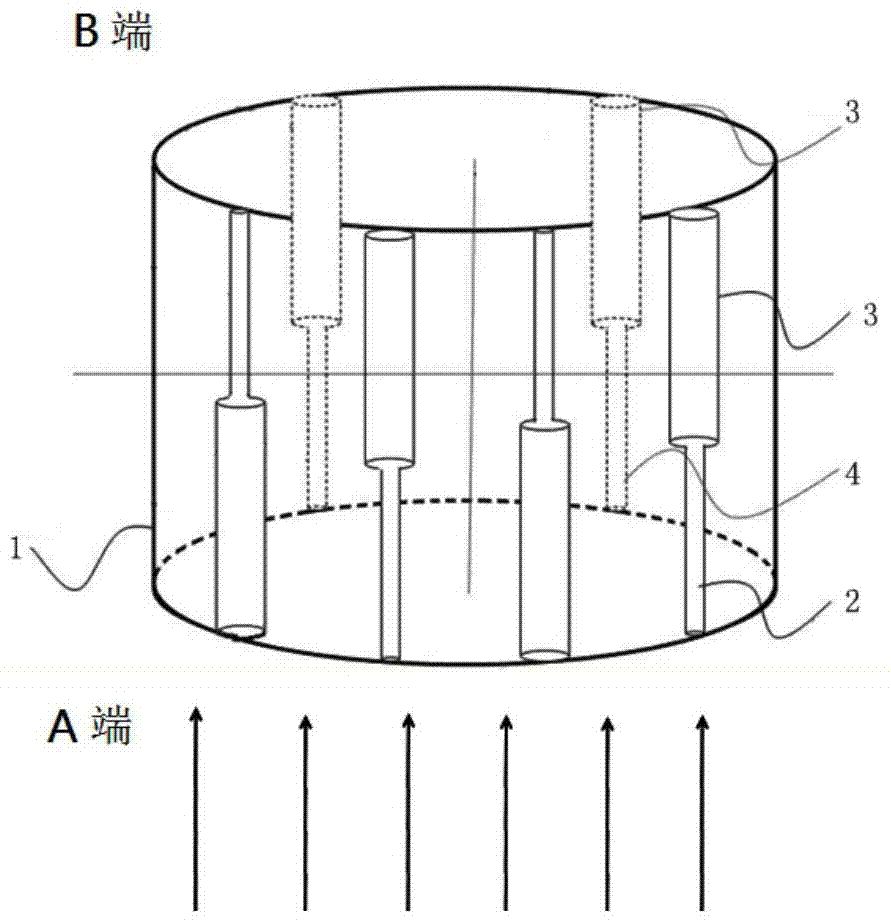

[0045] A polystyrene smoke filter device with a diameter of 6 mm and a length of 20 mm was manufactured by an injection molding process. The appearance is cylindrical, and the interior has 6 microchannels evenly distributed, and its cross-sectional shape is circular. The inner diameter of the first 10 mm section of the micro-channel is 0.2 mm, and the inner diameter of the last 10 mm section is 0.4 mm. Among the 6 flow channels, the small inner diameter sections of 3 flow channels face upwards, and the large inner diameter sections of the other 3 flow channels face upwards, which are evenly distributed to ensure that the smoke filter device has a front-to-back symmetrical structure.

Embodiment 2

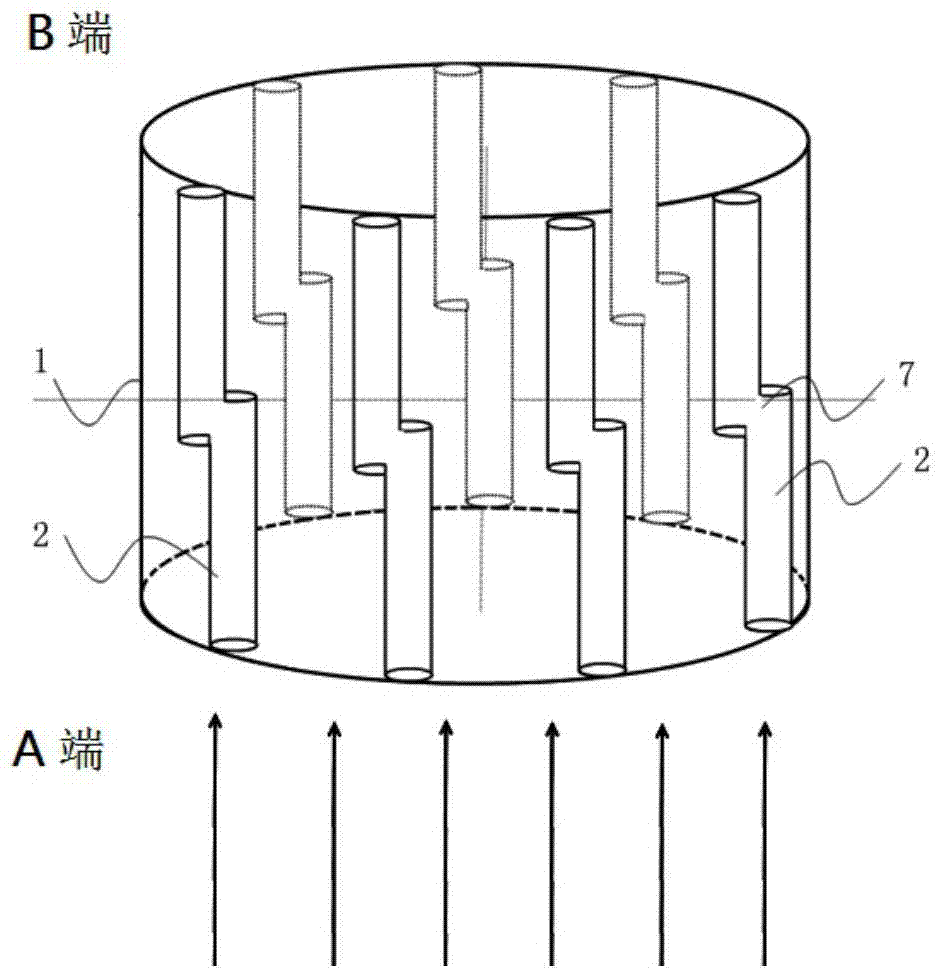

[0047] A polybutylene succinate smoke filter device with a diameter of 10 mm and a length of 5 mm was manufactured by an injection molding process. The appearance is cylindrical, and the inside has 8 micro-channels evenly distributed, and its cross-sectional shape is a circle with a diameter of 1 mm. The middle of the microchannel has a bend.

Embodiment 3

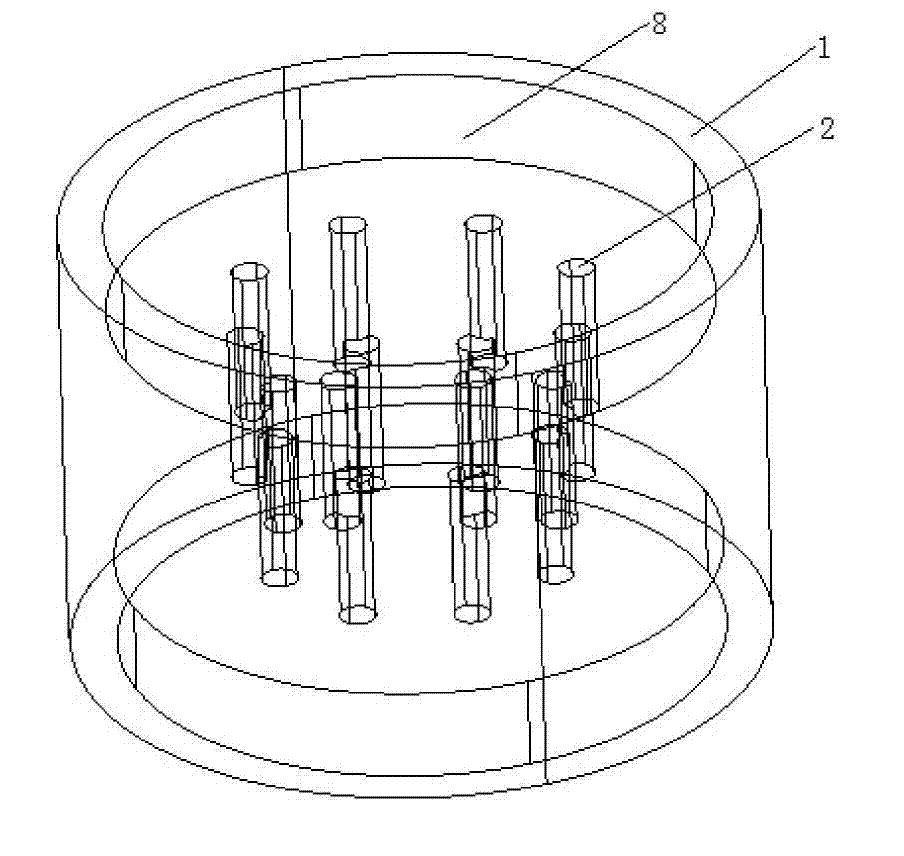

[0049] A styrene-acrylonitrile copolymer flue gas filter device with a diameter of 4 mm and a length of 25 mm was manufactured by an injection molding process. It is cylindrical in appearance, with recesses 8 with a height of 3 mm at its upper and lower ends, and a plurality of micro-flow channels evenly distributed inside, and its cross-sectional shape is circular. Uniform distribution ensures that the flue gas filter has a front-to-back symmetrical structure.

[0050] As a variant, it is also possible to use Figure 4 In the flow channel structure shown, the front end of the micro-channel is a square with a side length of 0.2 mm, and the end is a square with a side length of 0.3 mm, and its longitudinal cross-sectional shape is trapezoidal. A total of 8 flow channels are constructed, of which 4 flow channels have small inner diameter ends facing upwards, and the other 4 flow channels have large inner diameter ends facing upwards, so as to ensure that the filter device has a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com