Double-fluid spray gun for denitration

A dual-fluid spray gun and denitration technology, applied in liquid spray devices, spray devices, dispersed particle separation, etc., can solve problems such as hidden dangers in production safety, short service life of the gun barrel, corrosion of the water wall lining, etc., and achieve long service life, High production safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0010] The present invention will be further described below in conjunction with the drawings and specific embodiments.

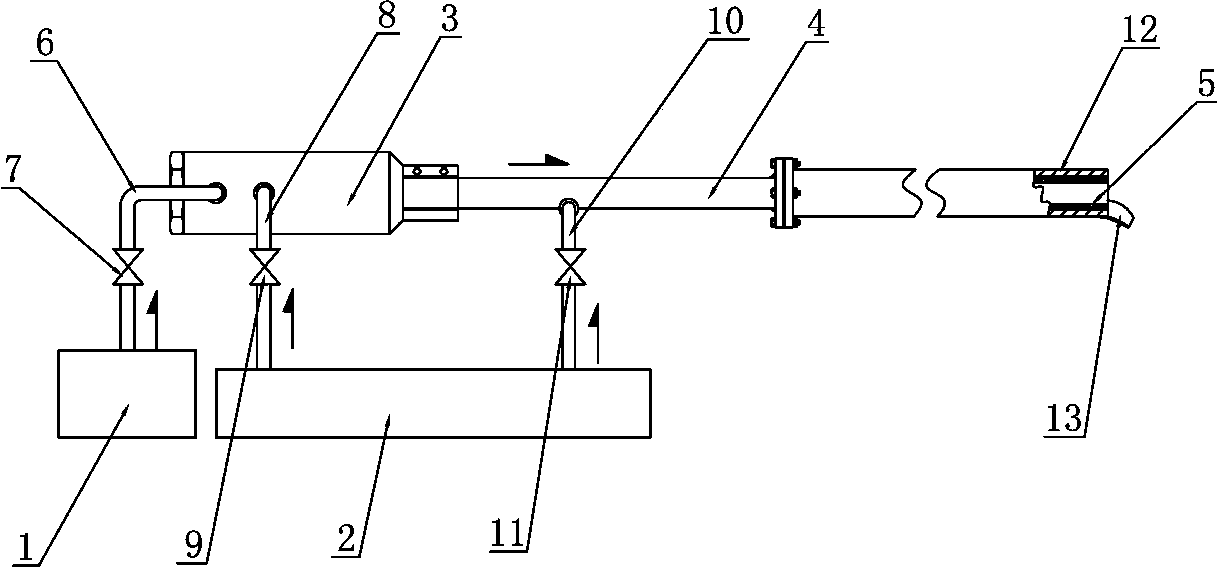

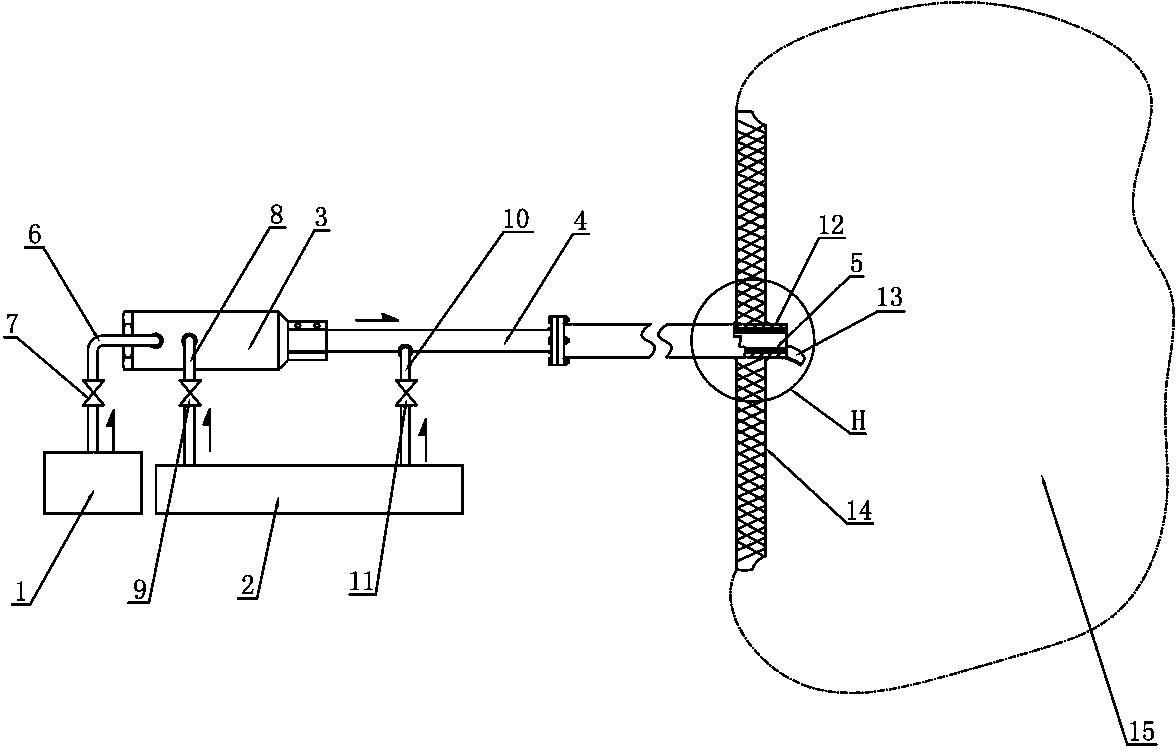

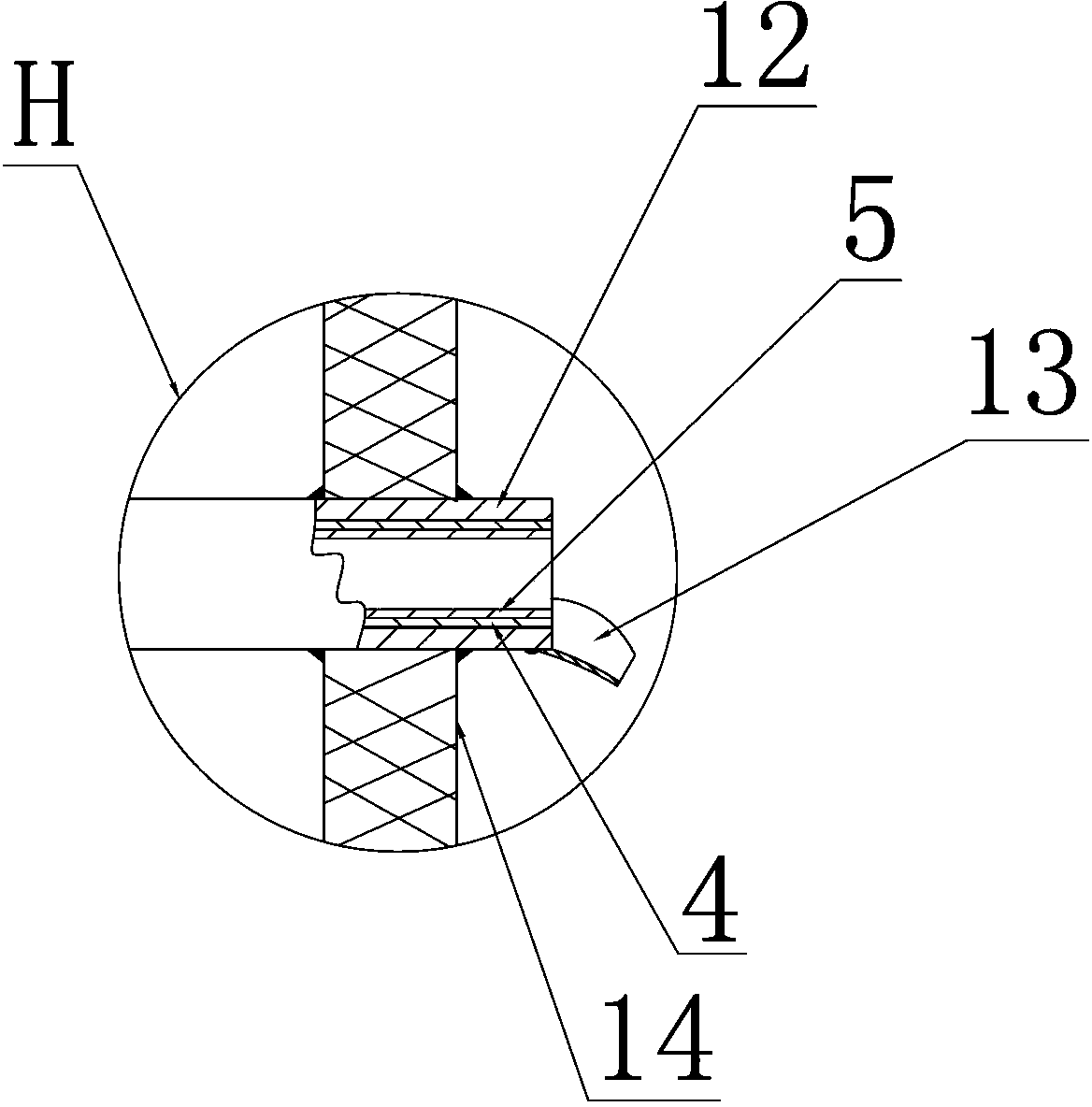

[0011] Such as figure 1 , figure 2 , image 3 As shown, the described two-fluid spray gun for denitrification includes an ammonia solution tank 1, a compressed air storage device 2, a gas-liquid mixing device 3, and a barrel 4 connected with the gas-liquid mixing device 3. The gun barrel 4 at the nozzle of the pipe 4 is equipped with a nozzle 5; the gas-liquid mixing device 3 is provided with a solution inlet and a compressed air inlet, and the gun barrel 4 is provided with a protective gas inlet. The ammonia solution storage tank 1 enters through ammonia water. The liquid pipe 6 communicates with the solution inlet of the gas-liquid mixing device 3, and the ammonia water inlet pipe 6 is provided with a liquid inlet regulating valve 7; the compressed air storage device 2 is compressed by the first inlet pipe 8 and the gas-liquid mixing device 3 The air inlet...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap