Mechanical sheet perforating machine

A punching machine and mechanical technology, applied in the field of punching machines, can solve the problems of stacking, low tensile strength, and roll rolls, etc., and achieve the effects of avoiding stacking, low tensile strength, and eliminating tension.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

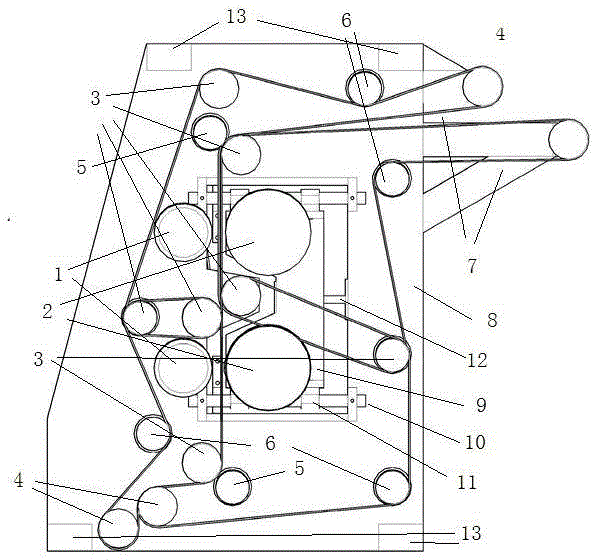

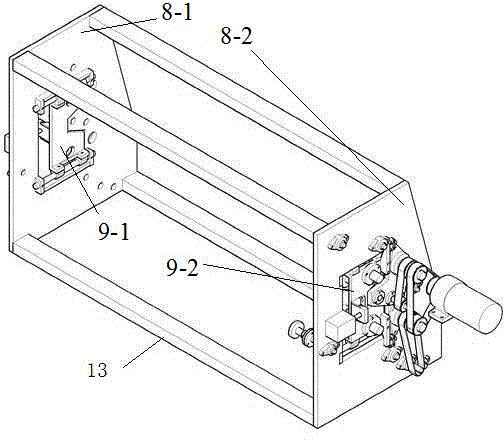

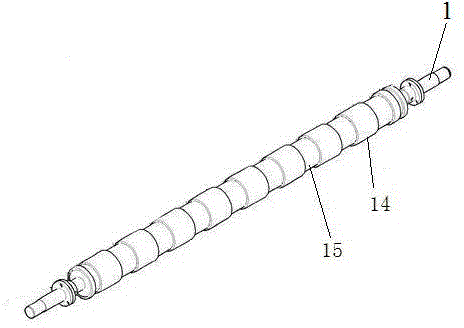

[0024] Such as Figure 1-7 As shown, the punching machine includes a punching needle roller 1, a rubber idler roller 2, a transmission roller 3, a guide roller 4, a limit roller 5, a tension roller 6, a belt 7, a wallboard 8, a moving wallboard 9, a moving Wall panel cylinder 12 and support frame 13, wall panels 8 are respectively installed on both sides of support frame 13, movable wall panels 9 are installed on the wall panels 8, two perforating needle rollers 1 are installed from top to bottom between the wall panels 8, punching Punching wheels 14 are installed at intervals on the needle roller 1, two rubber idlers 2 are installed between the moving wallboards 9, the horizontal position of the rubber idlers 2 is respectively relative to the punching needle roller 1, and the transmission roller 3, A group of belts 7 are wound between the guide roller 4, the limit roller 5, the tension roller 6, the drive roller 3, the guide roller 4, the limit roller 5 and the tension roller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com