Compressing glue injection method of injection molding machine

A technology for injection molding machines and injection cylinders, which is applied in the field of injection molding technology, and can solve problems such as unstable injection volume, insufficient sealing of nozzles, and impact on product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

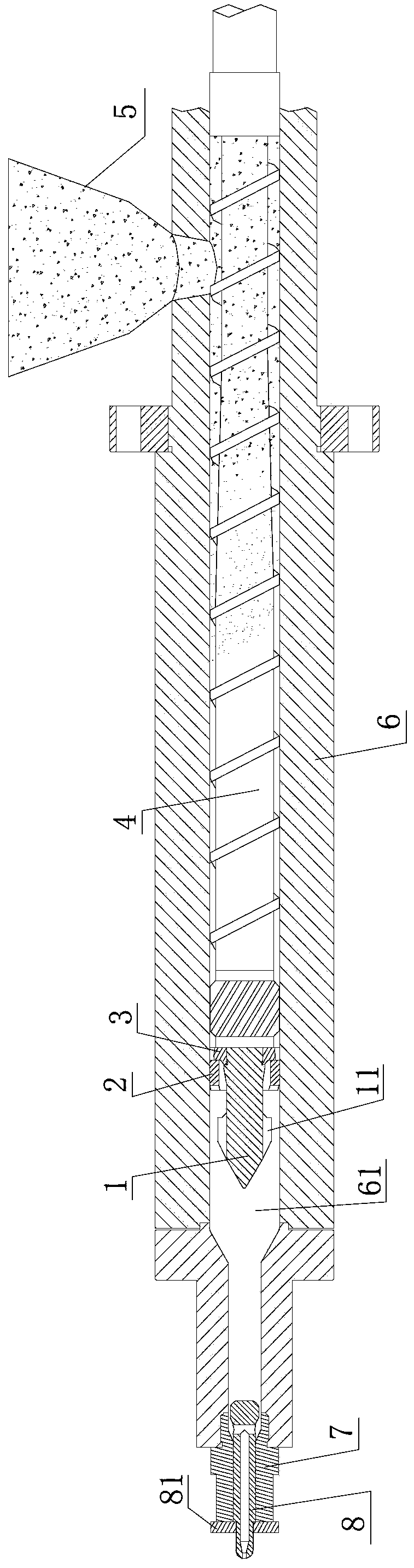

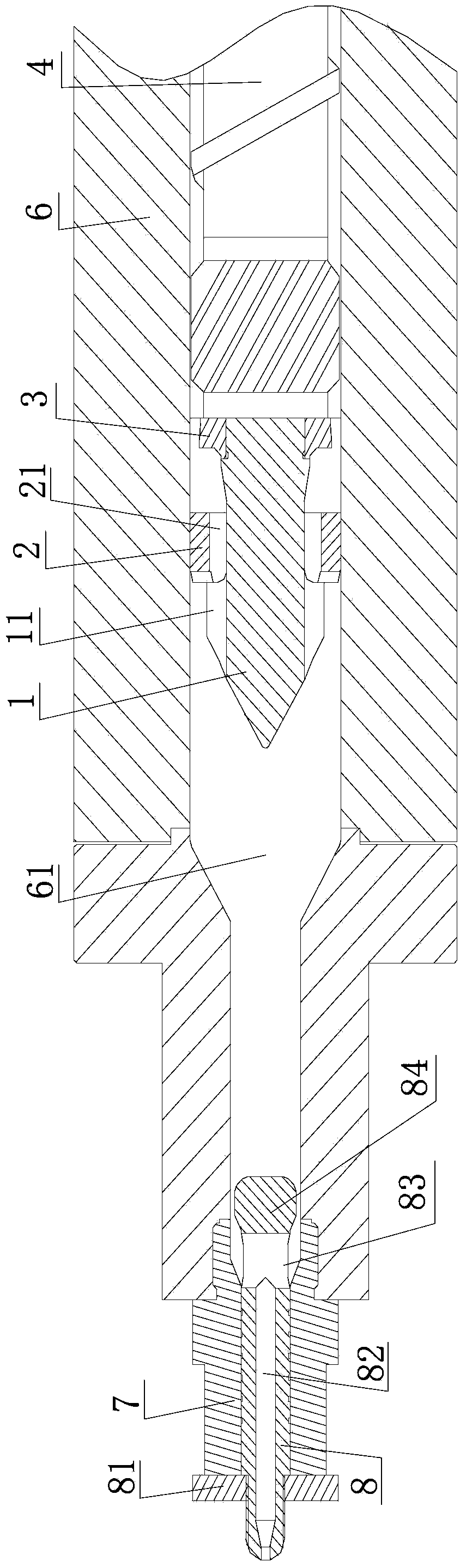

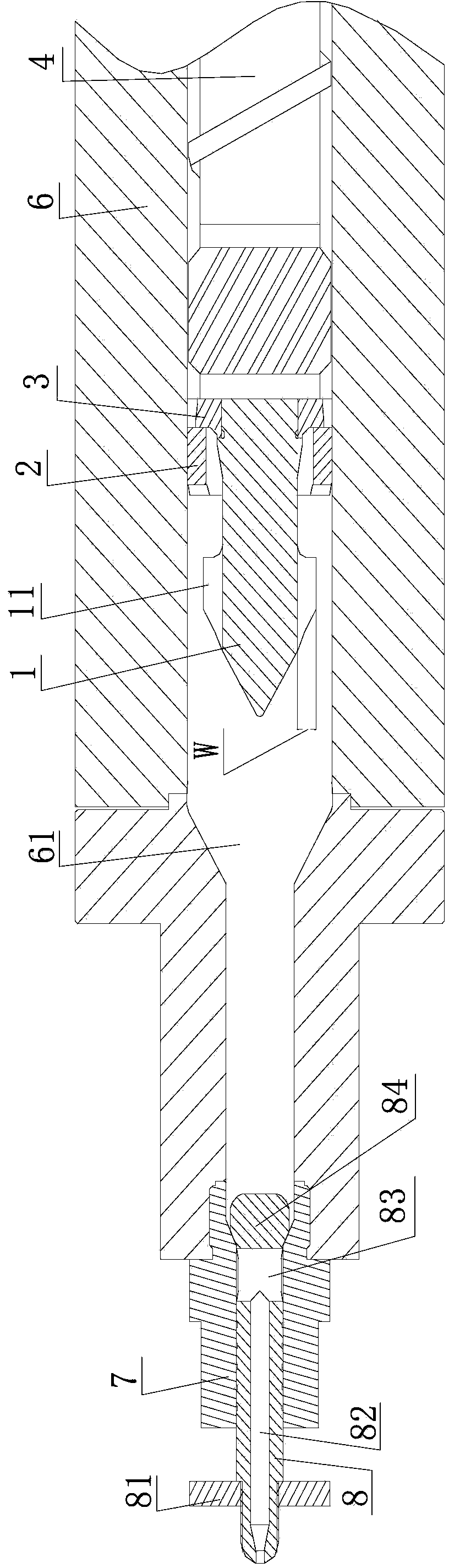

[0015] Such as Figure 1-3 As shown, the compression injection device of the injection molding machine includes a material tube 6, on which a hopper 5 is installed, and a screw 4 is arranged inside the material tube 6, and the screw 4 is driven by a sol motor to rotate the sol, and is driven by an injection cylinder Inject glue. A nozzle 7 is installed at the outlet of the material tube 6 , and a non-return nozzle 8 is installed on the nozzle 7 and can move left and right along the inner wall of the nozzle 7 .

[0016] The anti-return nozzle 8 is located at one end of the outlet of the material tube 6 to limit the limit weight 84, the limit weight 84 is slightly larger than the inner diameter of the nozzle 7, and the right end of the nozzle 7 is formed with a spherical shape that matches the size of the limit weight 84. structure. The outer wall of the other end of the anti-reflection nozzle 8 is screwed with a limiting nut 81 . The center axis of the anti-return nozzle 8 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com