Splicing machine for finished product base bodies of air-entrapping blocks

A technology of aerated block and splicing machine, which is applied in the direction of packaging, etc., can solve the problems of increasing labor costs, unfavorable market promotion of finished product packaging lines, and increasing operation errors, so as to reduce labor costs and operation errors and meet the needs of automated operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

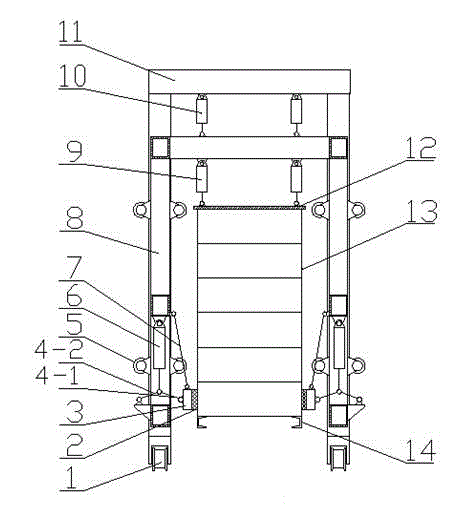

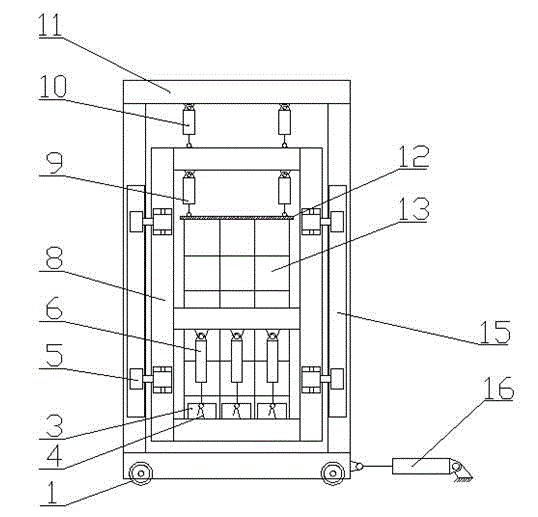

[0010] Referring to the accompanying drawings, an autoclaved aerated block body splicing machine includes a traveling wheel 1, a clamping rubber strip 2, a rubber strip fixing seat 3, a connecting rod 4-1, a connecting rod 4-2, a clamping cylinder or an oil cylinder 6. Swing rod 7, clamping frame 8, supporting cylinder or oil cylinder 9, lifting cylinder or oil cylinder 10, walking frame 11, supporting rubber strip 12, guide rail 15, walking pushing device 16, and walking wheels are installed on both sides of the bottom of the walking frame , can walk along the track, the clamping rubber strip is installed on the side of the rubber strip fixing seat facing the aerated block body, and there is a hinge hole at the tail end and the top of the rubber strip fixing seat, and the hinge hole at the tail end is connected with the connecting rod One end of 4-1 is connected, and the upper hinge hole is connected with one end of the swing rod, the other end of the connecting rod is hinged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com