Feeding and discharging device for hollow pipes and feeding and discharging method of feeding and discharging device

A hollow tube and tray technology, applied in the field of hollow tube loading and unloading devices, can solve the problems of difficult to meet production requirements, difficult operation, high labor intensity, etc., and achieve high adaptability, convenient operation, and simplified manufacturing process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

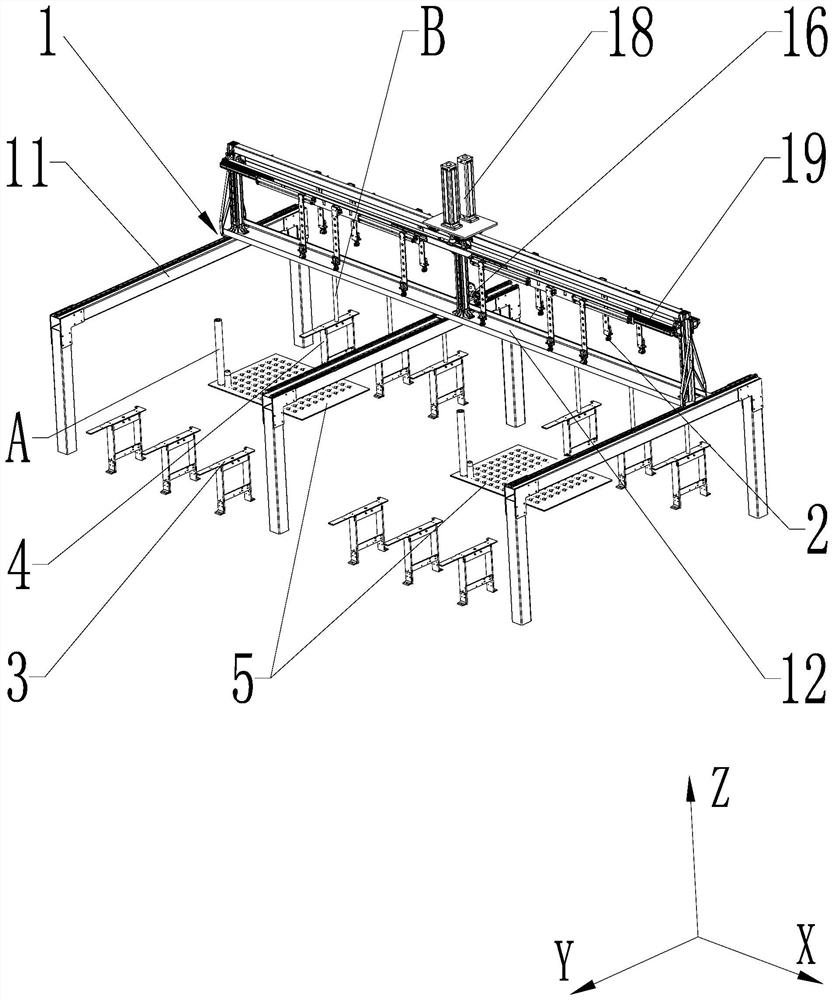

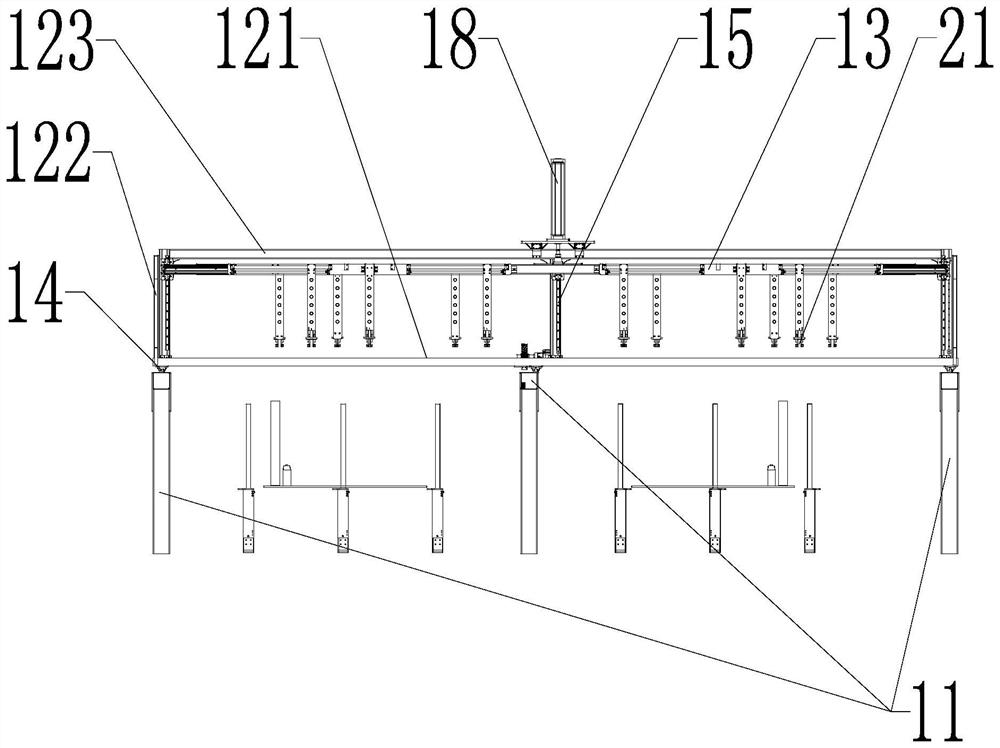

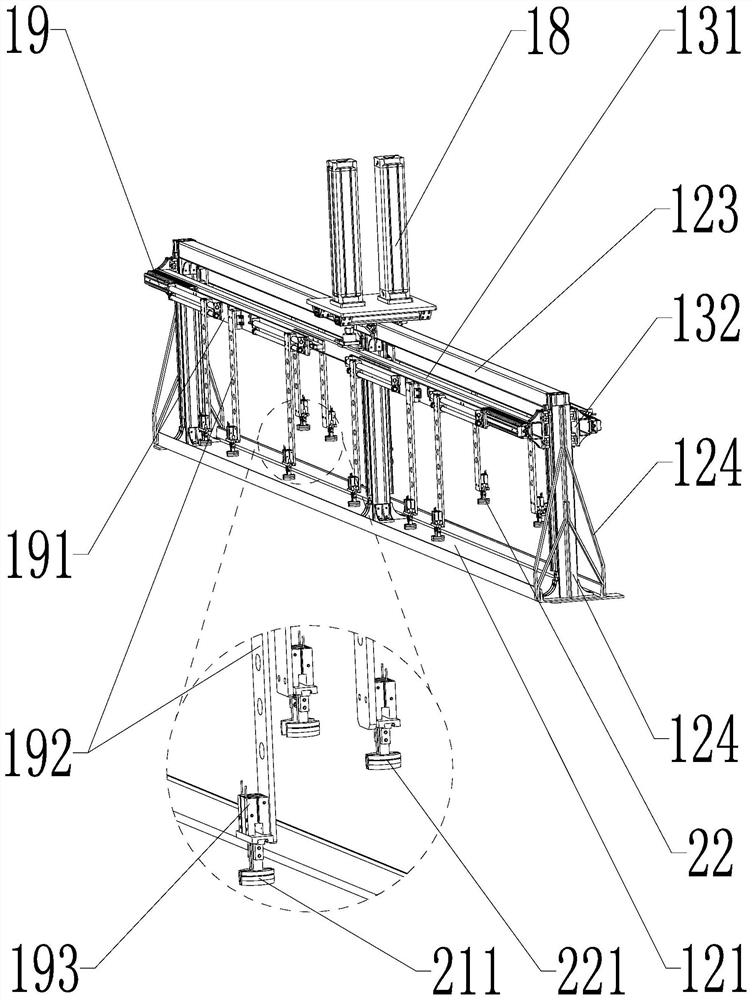

[0041] combine Figure 1 to Figure 7 , the present embodiment provides a loading and unloading device for hollow tubes, including: a frame 1, a clamping mechanism 2, a first placement table 3 and a second placement table 4, and a tray 5.

[0042] The frame 1 includes a plurality of frame-shaped bases 11 arranged side by side, and a beam frame 12 arranged on the frame-shaped bases 11 . The beam frame 12 is slidably supported on the frame base 11 along the Y-axis direction, and the beam frame 12 is extended along the X-axis direction. Wherein, the beam frame 12 is provided with a moving member 13, and the moving member 13 has a first moving part 131 and a second moving part 132 opposite to the different sides of the beam frame 12 along the Y-axis direction, and the two moving parts are arranged laterally along the X-axis direction , and can be controlled by different power sources to be slidably arranged on the beam frame 12 along the Z-axis direction.

[0043] Wherein, the cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com