Hoisting device for overhauling jackdrill head of mining trolley and hoisting method

A hoisting device and trolley technology, applied in the directions of transportation and packaging, load hoisting components, etc., can solve problems such as inconvenience and limitation of work, and achieve the effects of convenient maintenance, low manufacturing cost and high speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

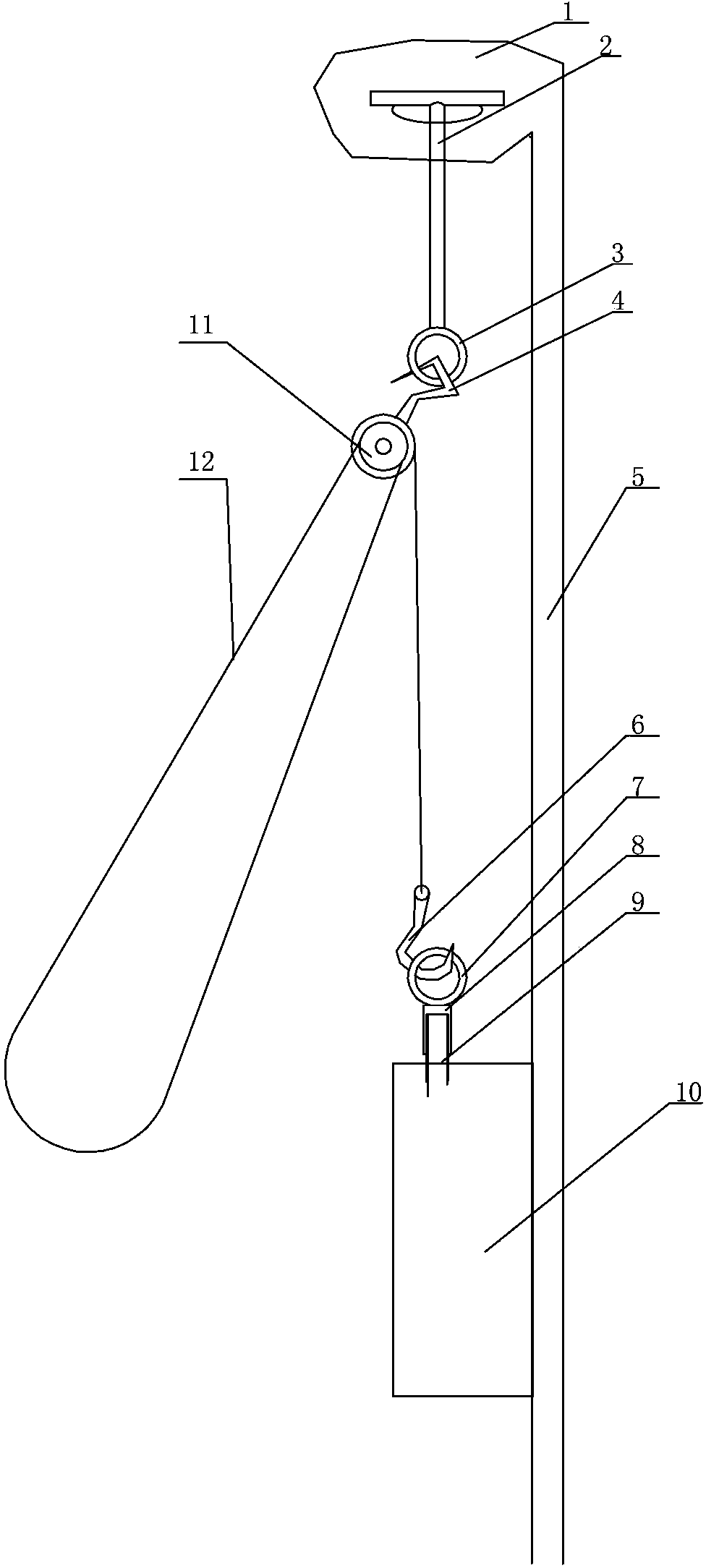

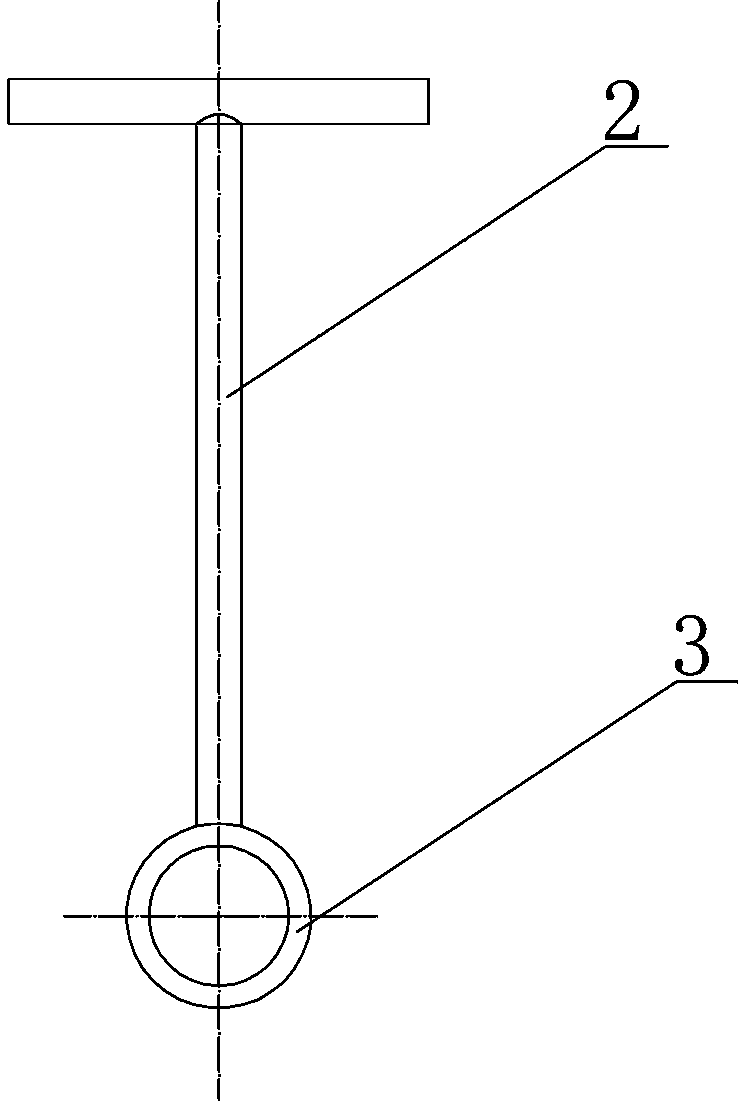

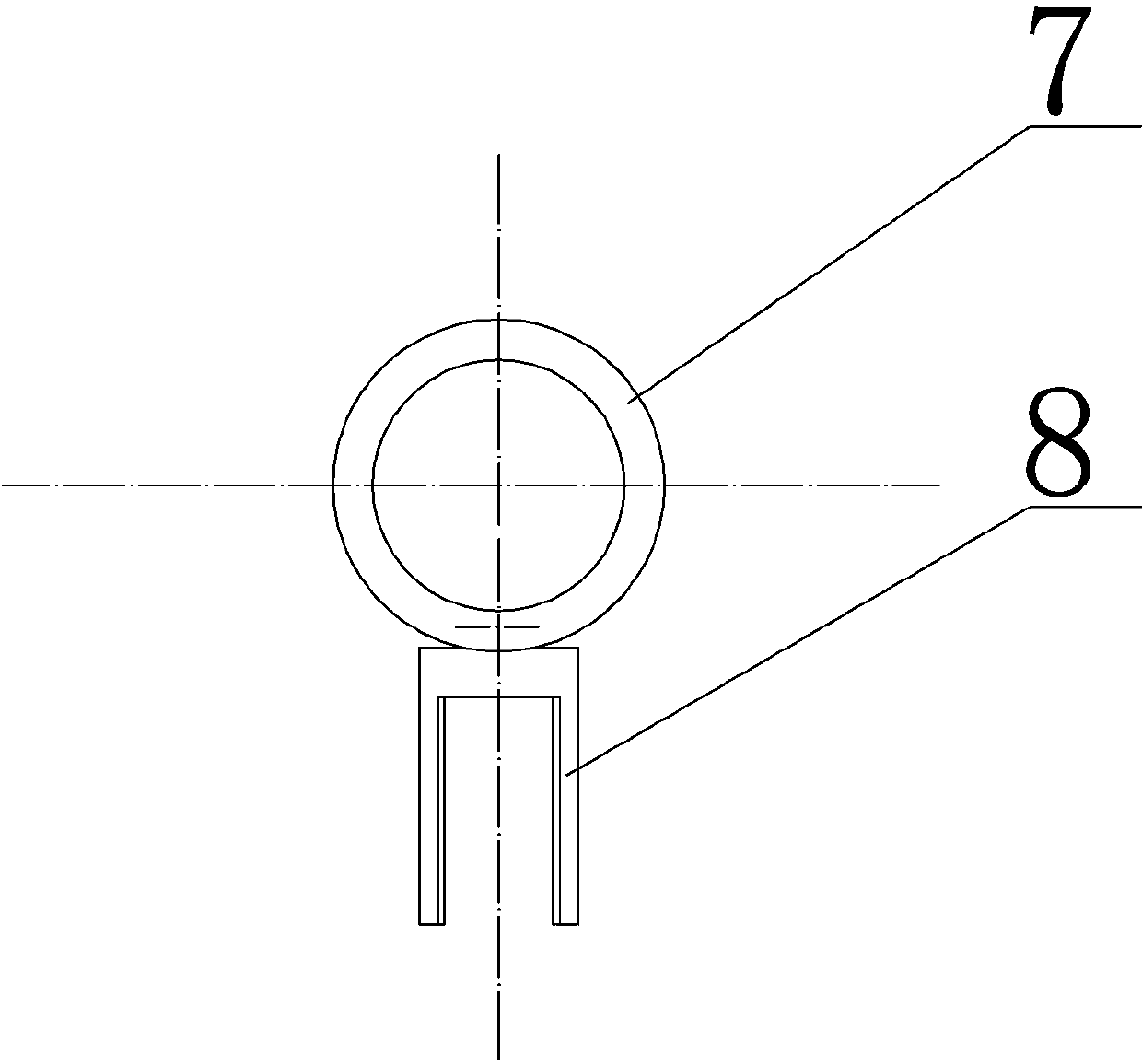

[0021] Such as Figure 1~3 As shown, a hoisting device for hoisting a rock drilling head of a mining jumbo for inspection and maintenance, including a clamping device 1 arranged on the upper part of the trolley slideway 5, and is characterized in that it also includes a hoisting upper part connected with the clamping device 1 in sequence, a hand pull The gourd and the hoisting lower part, the hoisting upper part is composed of a "T"-shaped steel structure 2 and the lower ring 3 welded at its lower end; The lower ring 3 of the lifting upper part is connected with the upper hook 4 of the chain block, and the lower lifting part is made of an internal thread sleeve that matches the externally threaded shank 9 of the rock drill head. The cylinder 8 and the upper ring 7 fixedly connected to one end of the internal thread sleeve 8 are composed. The upper ring 7 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com