Pretreatment equipment and method for glazing of ceramic body

A ceramic blank and pre-treatment technology is applied in the field of pre-treatment equipment for glazing of ceramic blanks, which can solve the problems of unstable quality, low efficiency, blank body loss, etc., and achieve convenient adsorption force, scientific and reasonable structure, and production efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

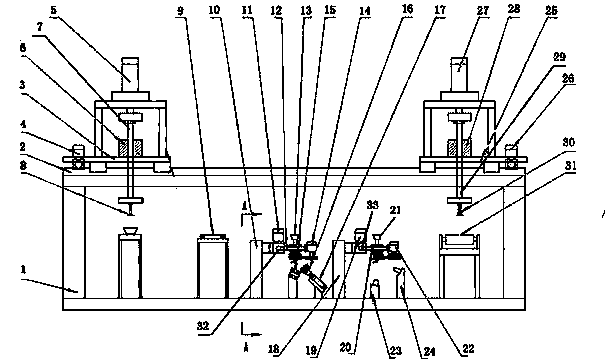

[0042] The ceramic green body glazing pre-treatment equipment formula that present embodiment provides works like this:

[0043] A. The green body delivery device 1 absorbs the ceramic body by the vacuum suction of the delivery device 1 suction cup 8, transports it to the wax plate 9, controls the descending distance of the delivery device 1 suction cup 8, and draws the bottom edge of the ceramic body immerse in wax;

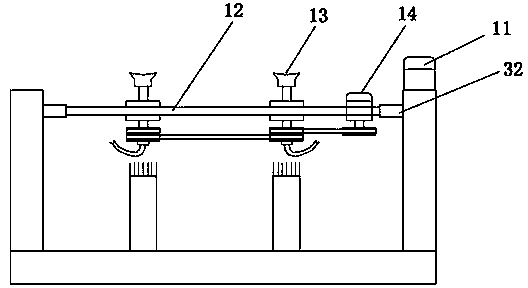

[0044] B, green body delivery device 1 transports the ceramic green body soaked in wax to the suction cup 13 of the dust sweeping device, the green body delivery device 1 stops vacuum suction, the delivery device 1 suction cup 8 rises away from the ceramic green body, and the dust sweeping device suction cup 13 passes Vacuum sucks the ceramic green body, and the dust-sweeping rotating mechanism rotates downward to the vertical direction, and the outside and the inside of the ceramic green body are respectively in contact with the outer sweeping dust sweep 15 and...

Embodiment 2

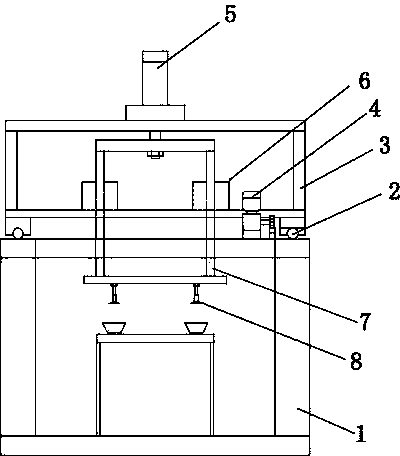

[0051] Such as figure 2 with image 3 As shown, the ceramic body glazing pre-treatment equipment of the present invention can be designed as two parallel groups, which only need to be controlled by a set of motors and telescopic power sources, which not only improves production efficiency but also reduces costs. That is, two parallel delivery device I guide rods 7 are controlled by a resistance delivery device I telescopic power source 5; a group of delivery device II telescopic power sources control two parallel delivery device II guide rods 29; a group of sweeping suction cup drive motors 14 drives two parallel dust sweeping device suction cups 13 to rotate through gear transmission; a group of water spray suction cup rotating motors 19 drives the parallel two water spray device suction cups 21 to rotate through gear transmission.

[0052] The dust-sweeping rotating mechanism and the water-spraying suction cup rotating mechanism also all utilize gear transmission, and two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com