Yield-increasing and energy-saving technology of carbon dioxide stripping urea and equipment of carbon dioxide stripping urea

A carbon dioxide and energy-saving equipment technology, which is applied in the field of urea medium-pressure decomposition and absorption and vacuum pre-concentration, can solve the problems that methylammonium liquid cannot be distributed to form a film, the corrosion of equipment is intensified, and the stripping efficiency is reduced, so as to solve the problem of insufficient urea production capacity, production The effect of efficiency improvement and urea production capacity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

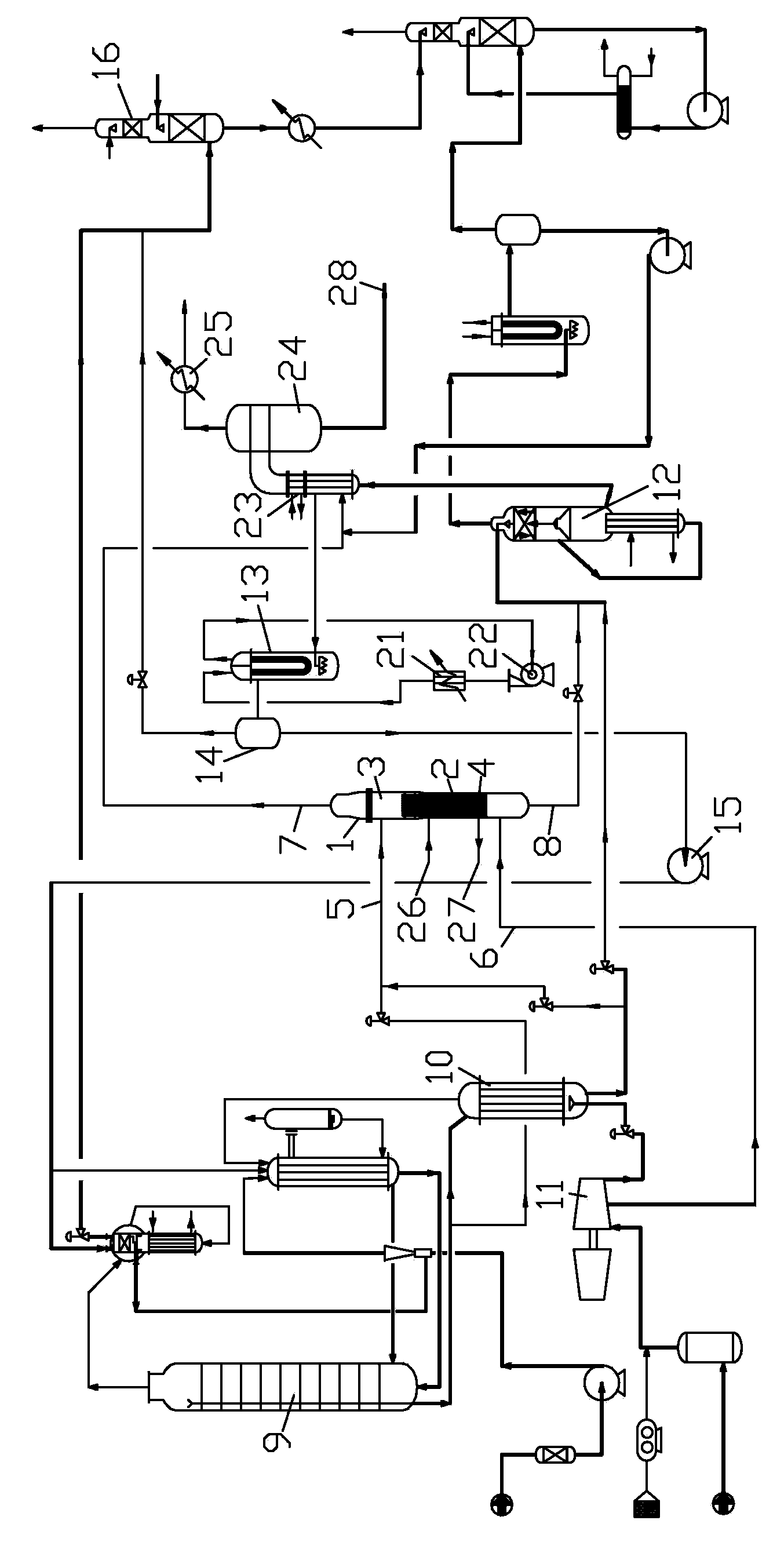

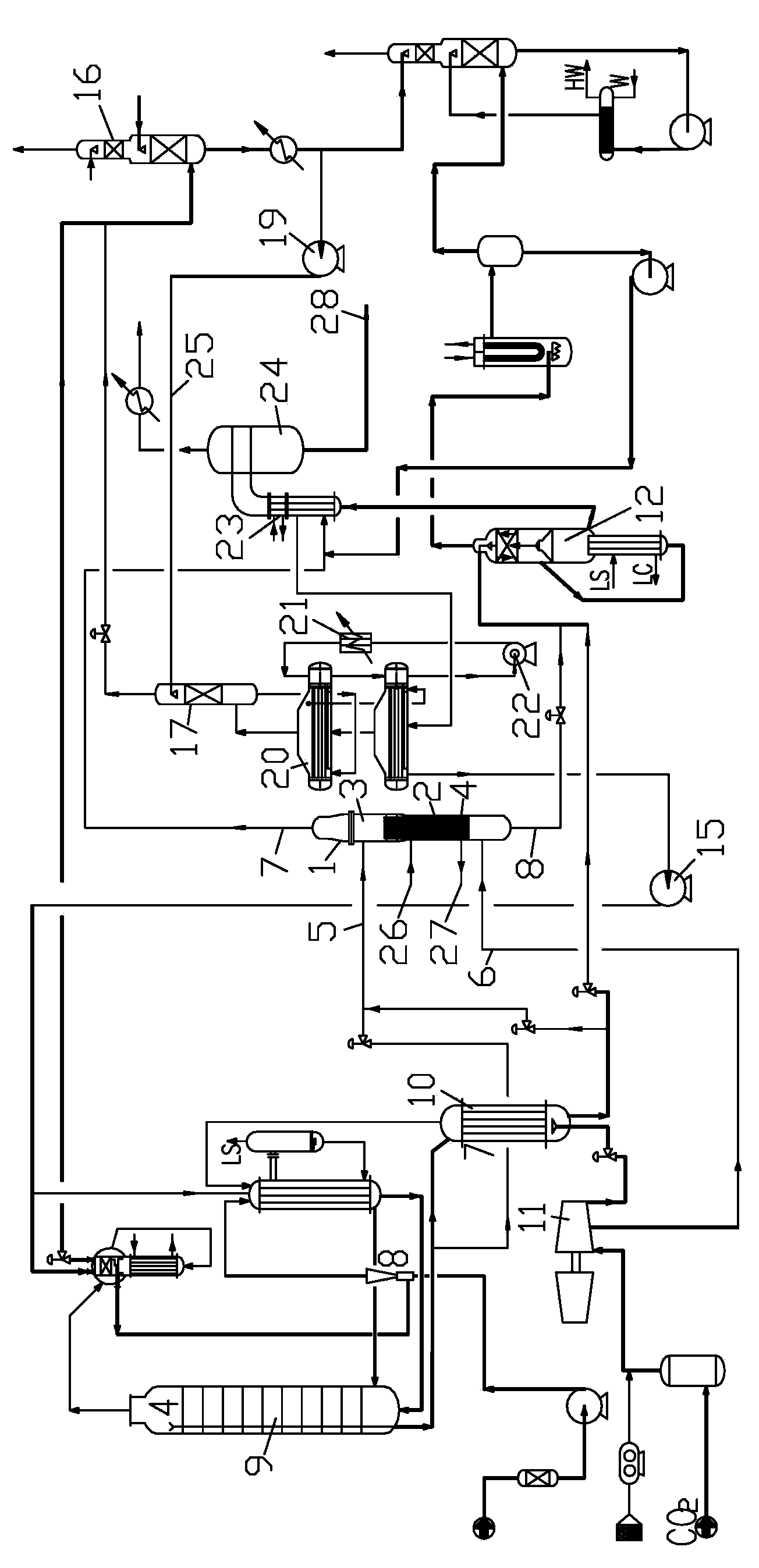

[0025] The specific embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0026] In order to achieve the above object, the technical solution of the present invention is achieved in this way.

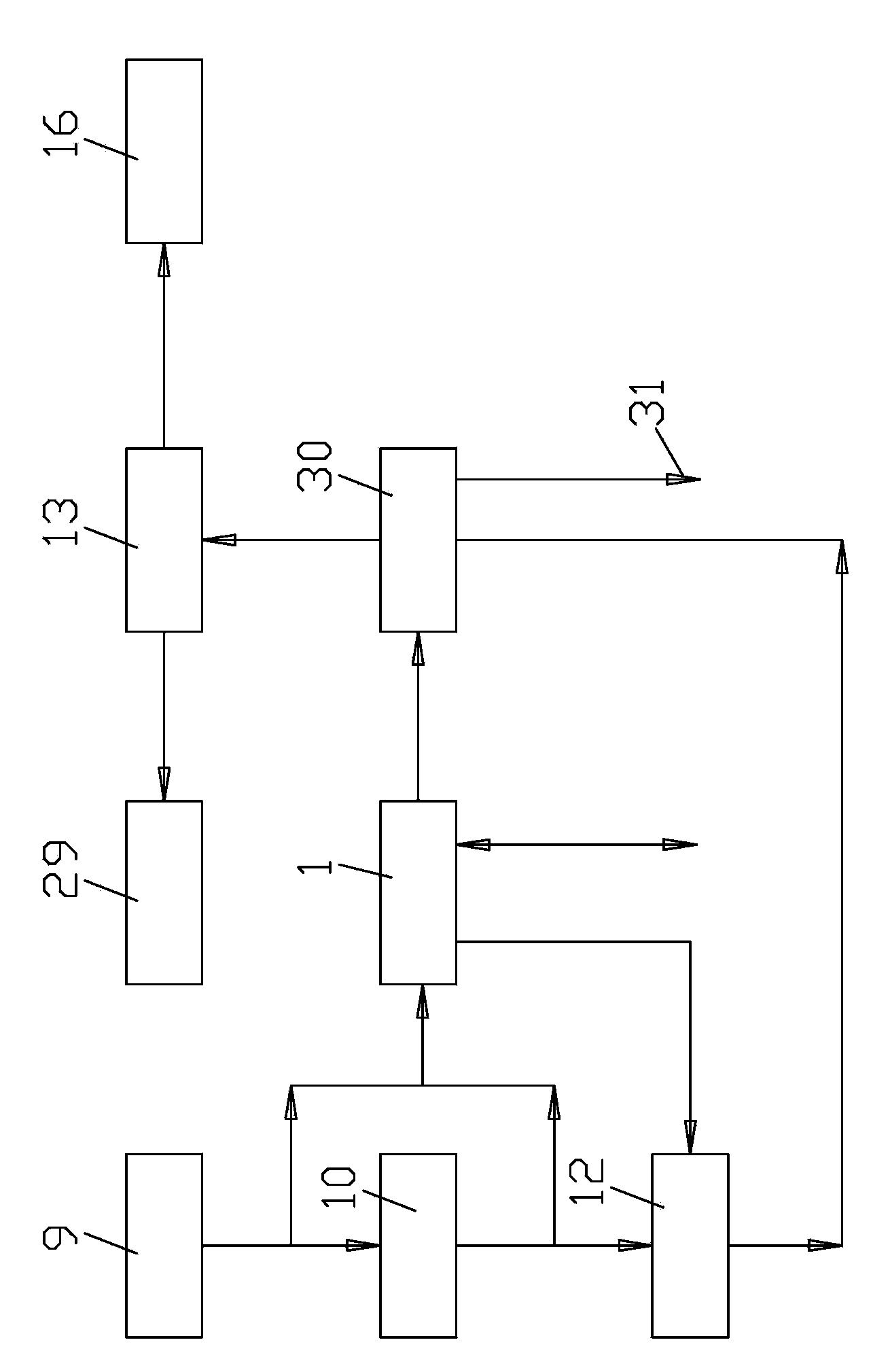

[0027] Such as figure 1 As shown, the production-increasing and energy-saving technology of carbon dioxide stripping urea involved in the present invention is carried out in the following steps.

[0028] .A. The urea reaction liquid from synthesis tower 9 with a temperature of 180~185°C and a pressure of 14.0~14.2MPa (G) is divided into two parts, most of which urine is sent to high-pressure stripper 10 for equal pressure stripping and decomposition, about 1 / 3 of the stripped urine is decompressed to 1.7~2.0MPa(G), and a small part of the bottom liquid of the synthetic tower 9 is directly decompressed to 1.7~2.0MPa(G). Pressure stripping decomposition tower 1 carries out stripping and decomposition.

[0029] B....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com