A kind of preparation method of neoprene sponge

A kind of neoprene rubber and sponge technology, applied in the direction of coating, etc., to achieve the effect of reducing production cost, reducing loss ratio and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following describes the implementation of the present invention in detail with reference to the accompanying drawings. The accompanying drawings are for reference and explanation purposes only, and do not constitute a limitation on the scope of protection of the patent of the present invention.

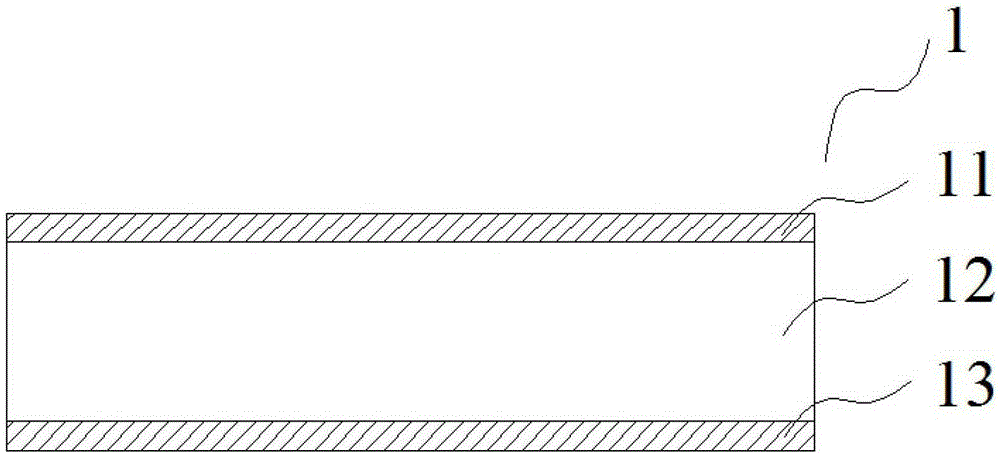

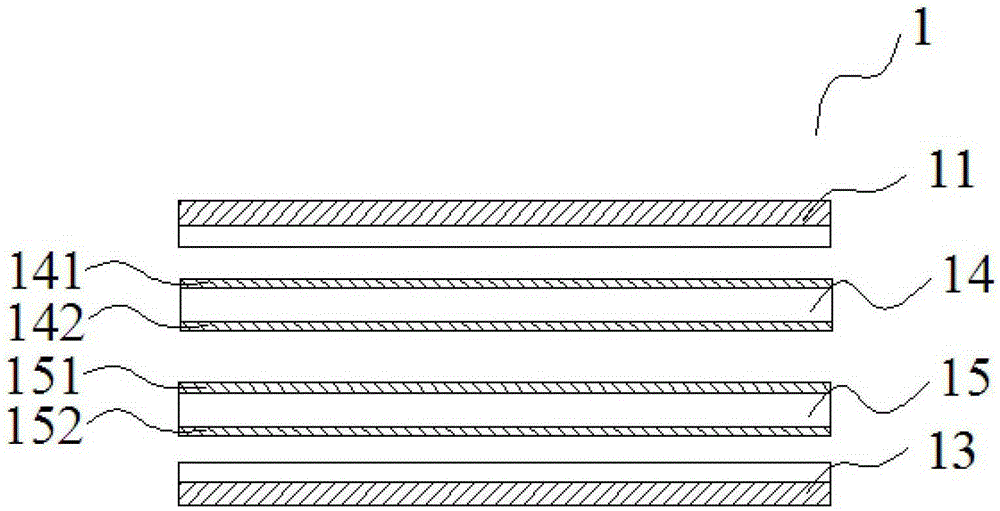

[0018] This embodiment provides a method for preparing a neoprene sponge. Neoprene is used as a foaming substrate, and after adding fillers, plasticizers, antioxidants, vulcanization systems, and foaming systems, the neoprene is made into neoprene. Rubber sponge, such as figure 1 As shown, the neoprene sponge 1 includes an upper skin layer 11, a middle layer 12, and a lower skin layer 13. The density of the upper skin layer 11 and the lower skin layer 13 is greater than the density of the middle layer 12, including:

[0019] Separating at least one intermediate layer from the intermediate layer of the neoprene sponge by a cutting step;

[0020] A fine embossing and pressing step i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com