Washing machine transmission device, washing machine driving mechanism and washing machine

A transmission device and drive mechanism technology, applied in washing devices, other washing machines, textiles and papermaking, etc., can solve the problems of high processing technology requirements, high product qualification rate, difficult processing, etc., to avoid installation procedures, simplify processing technology, The effect of ensuring structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

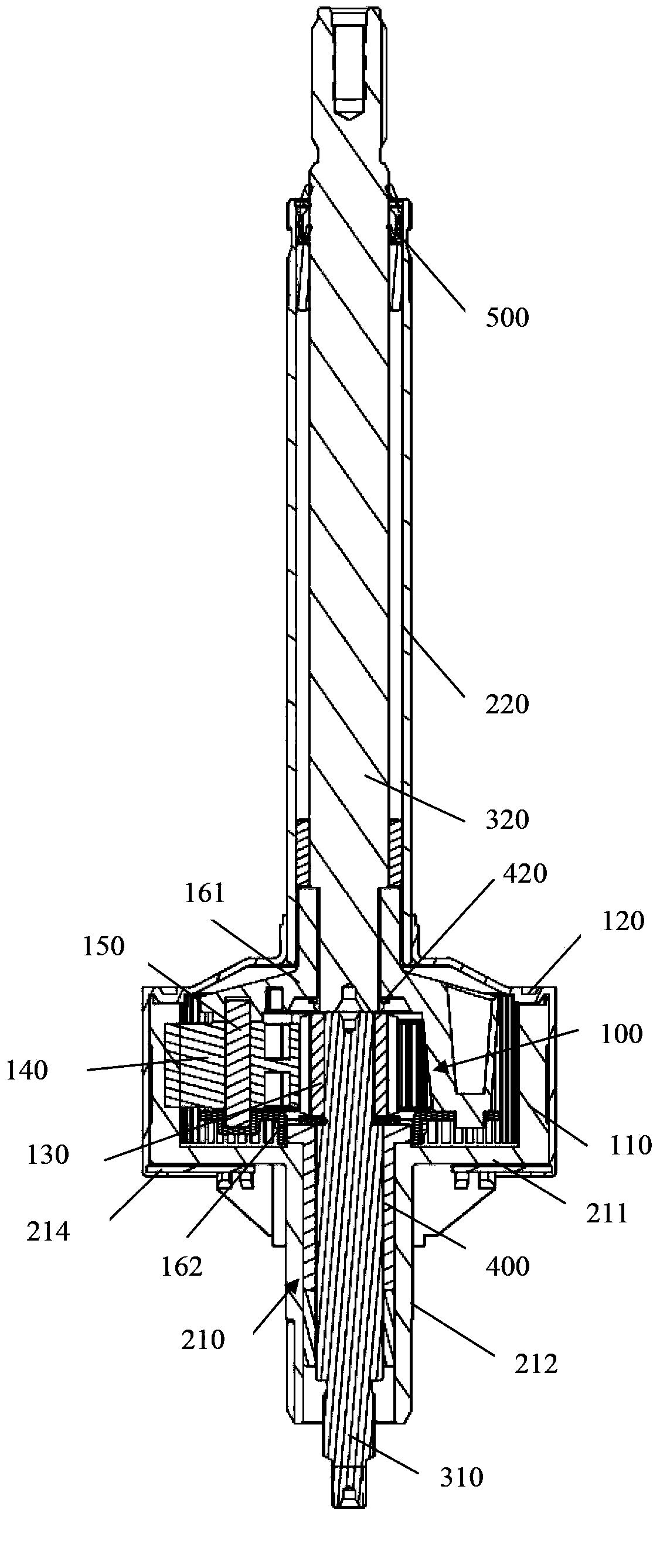

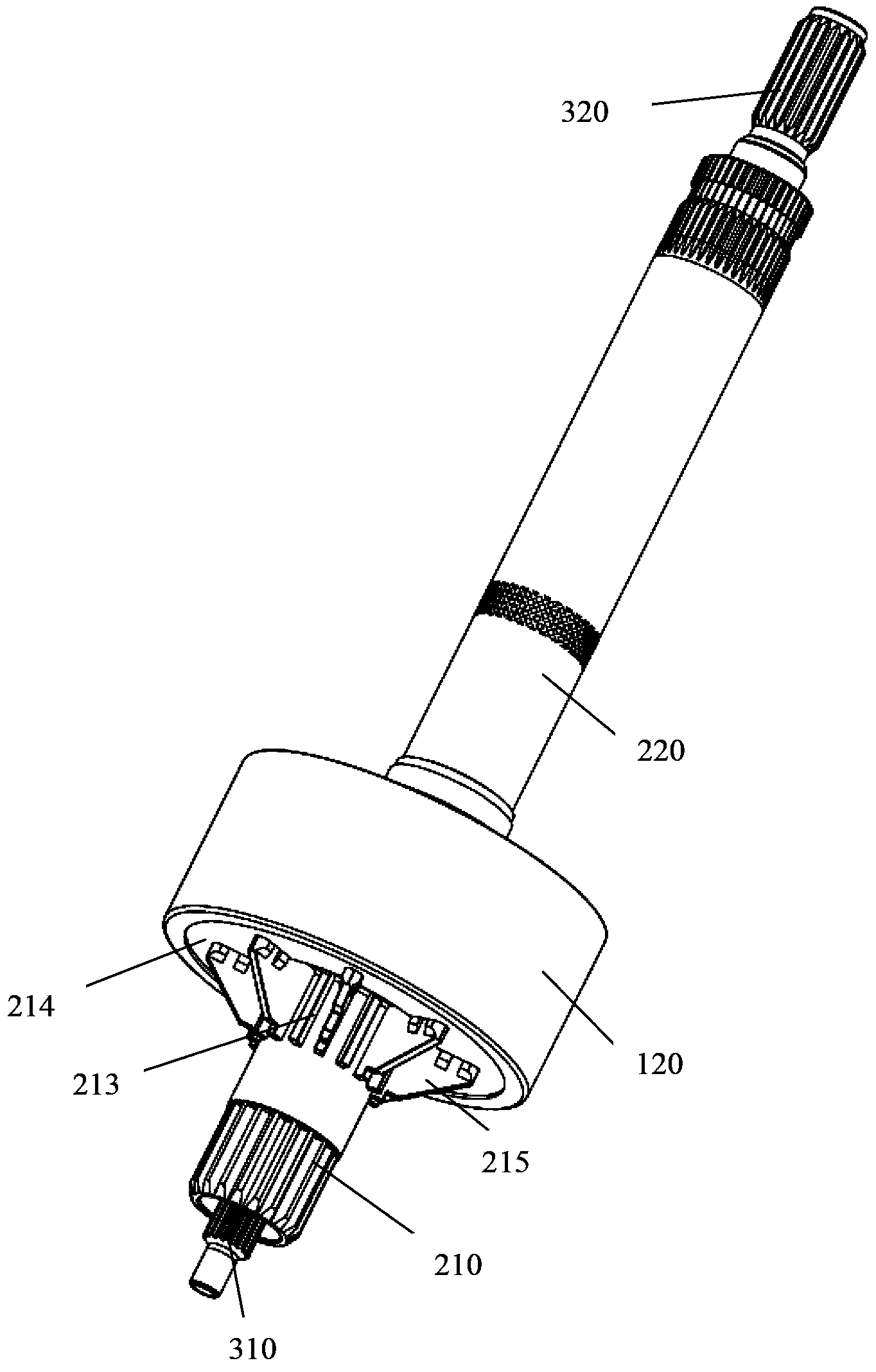

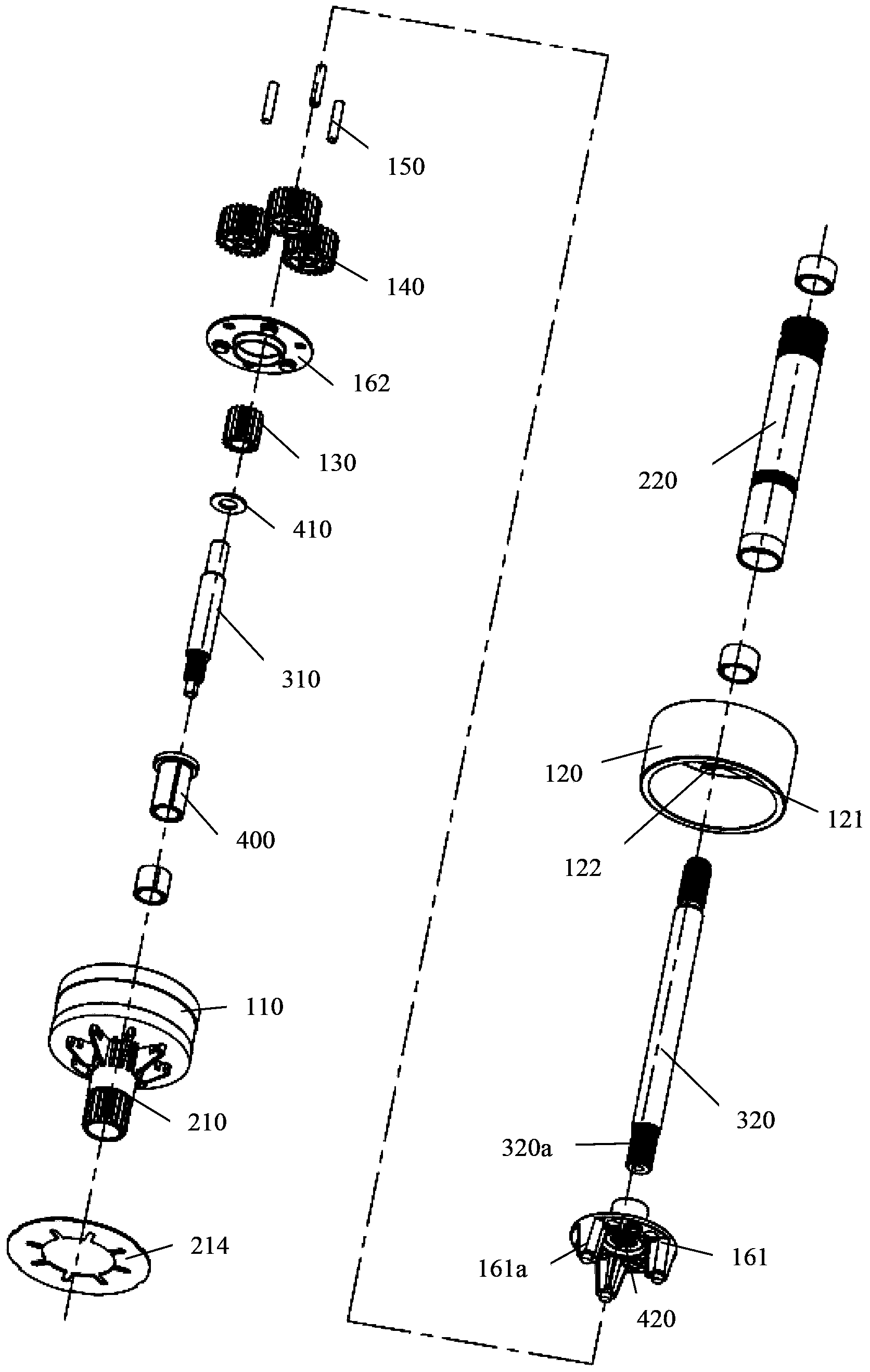

[0030] The embodiment of the present invention discloses a transmission device for a washing machine, which includes a planetary gear train, a drive shaft, and a drive sleeve that is sleeved on the outside of the drive shaft and rotatably connected to it, wherein the drive sleeve includes an input sleeve and an output sleeve, and the planetary The gear train includes an inner ring gear, and an inner ring gear retaining sleeve located outside the inner ring gear and fixedly connected with it. The input shaft sleeve and the inner ring gear are integrally formed, and the inner ring gear retainer sleeve is fixedly connected with the output shaft sleeve.

[0031] The embodiment of the present invention also discloses a driving mechanism for a washing machine, which includes a motor, a transmission device and a clutch device. connect.

[0032] The embodiment of the present invention also discloses a washing machine, including a washing machine driving mechanism, a washing execution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com