Construction method of water drainage uplift pile

A construction method and technology of uplift piles, which are applied in sheet pile walls, foundation structure engineering, buildings, etc., can solve the problems of loss of uplift bearing capacity, corrosion of steel cages, etc., and achieve simple construction methods, avoid corrosion damage, and solve Effect of Drainage and Uplift Capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

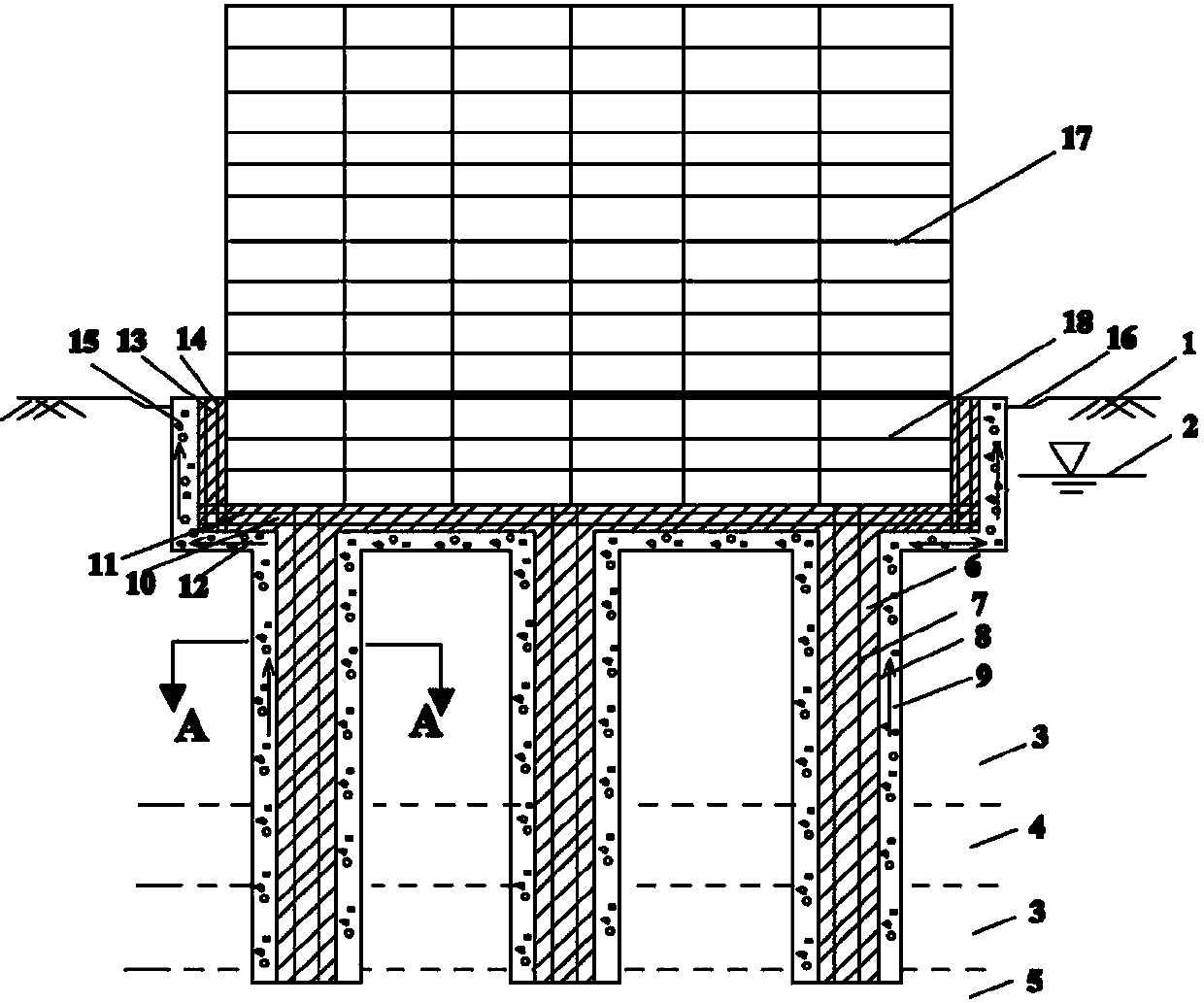

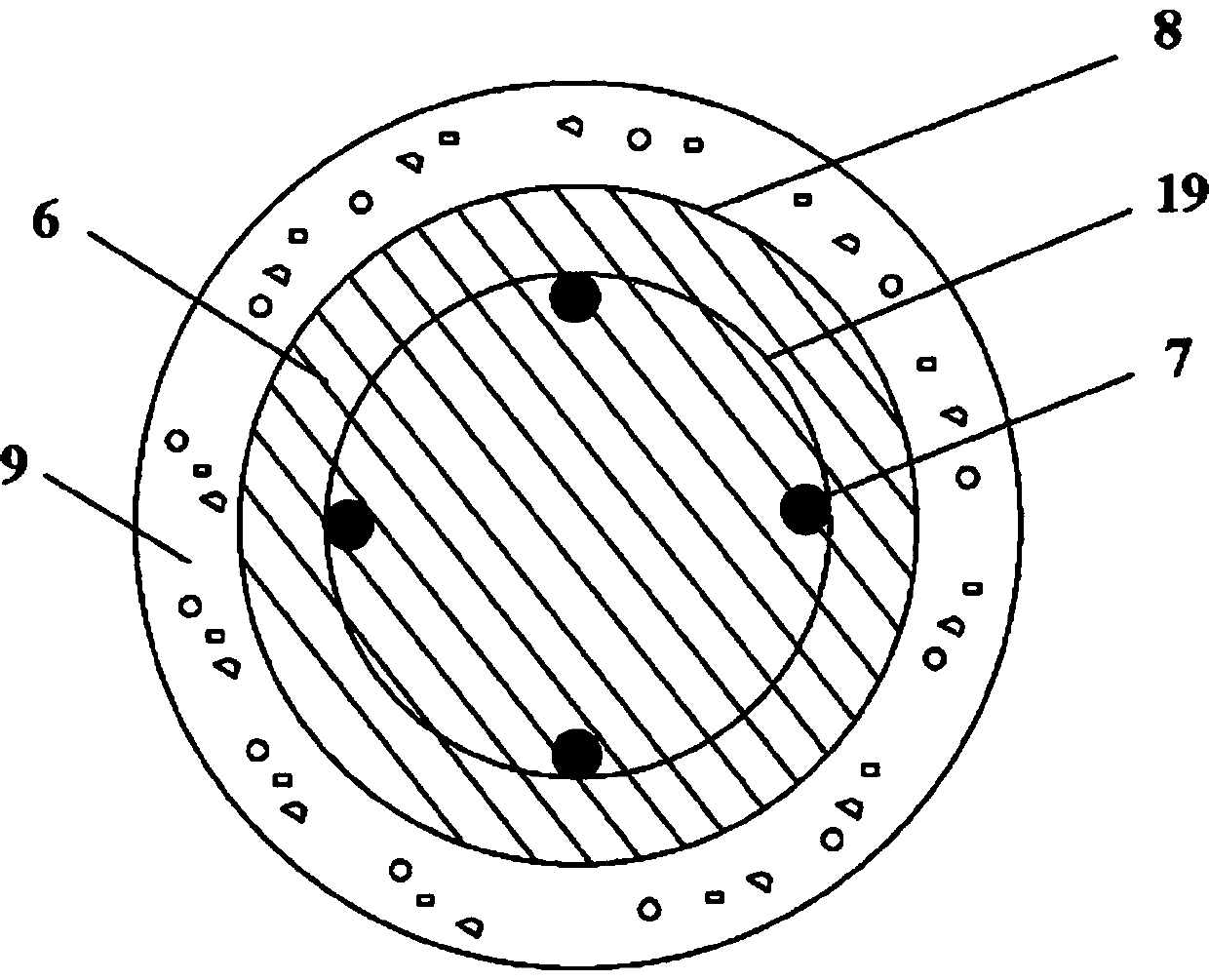

[0019] Depend on figure 1 , figure 2 It can be seen that a construction method of a drainage uplift pile comprises the following steps:

[0020] ⑴According to the design requirements, first level the construction site, measure and set out the lines on the ground surface 1, excavate the foundation pit according to the design position requirements, lower the groundwater level 2, ensure the safety of the foundation pit, and construct permeable plain concrete retaining walls in turn against the pit wall 15 and impermeable reinforced concrete retaining wall 13, and excavate drainage ditch 16 near permeable concrete retaining wall 15 at the shallow layer of ground surface 1, and the width of drainage ditch 16 is 20cm~40cm (the present embodiment is 20cm ), the depth is 30㎝~50㎝ (40㎝ in this embodiment);

[0021] In step (1) of the present invention, the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com