Rotatable pentagonal impeller type vortex-induced vibration inhibiting device and method

A pentagonal impeller and vortex-induced vibration technology, which is applied in earthwork drilling, fluid flow, drilling equipment, etc., can solve the problems of limited application range and difficulty in the application of active suppression technology, and achieve the reduction of gravity effect, suppression of vortex-induced vibration, Not easy to corrode and damage the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

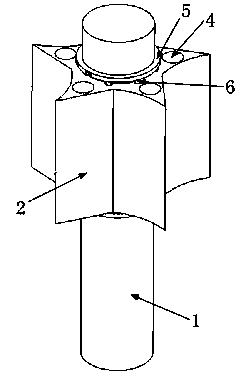

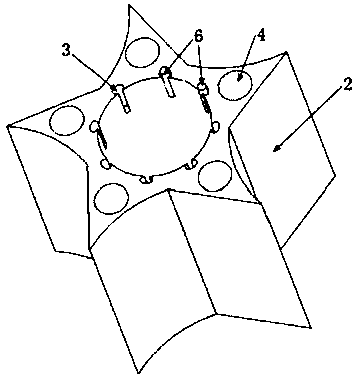

[0026] According to the slenderness ratio of the actual riser 1 and the perennial statistical information of local ocean waves and currents, a reasonable basic unit spacing is designed, and the required number n of basic units is calculated, then the number of pentagonal impellers is n, and the number of cylindrical rollers is n. The number is 16n, and the number of fixed snap rings is 2n.

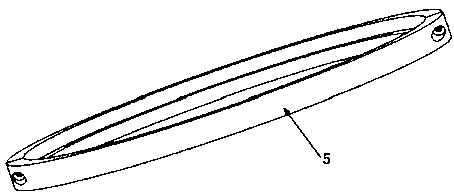

[0027] When installing a single basic unit, first, set the pentagonal impeller 2 on the riser 1 at a suitable position; then, insert the cylindrical roller 6 into the arc-shaped socket 3 at both ends of the pentagonal impeller 2; The fixed snap ring 5 is installed at both ends, so that the outer end surface of the cylindrical roller 6 is in contact with the inner step end face of the fixed snap ring 5, and the fixed snap ring 5 is fixed by bolt connection; so far, a basic unit has been installed. Subsequently, install the remaining base units in the same installation sequence.

[0028] Af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com