Centrifugal pump with greatly distorted blades

A centrifugal pump and vane technology, which is applied to the components, pumps, and pump elements of a pumping device for elastic fluids, and can solve problems such as blade twisting, energy loss, and reduced centrifugal pump efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

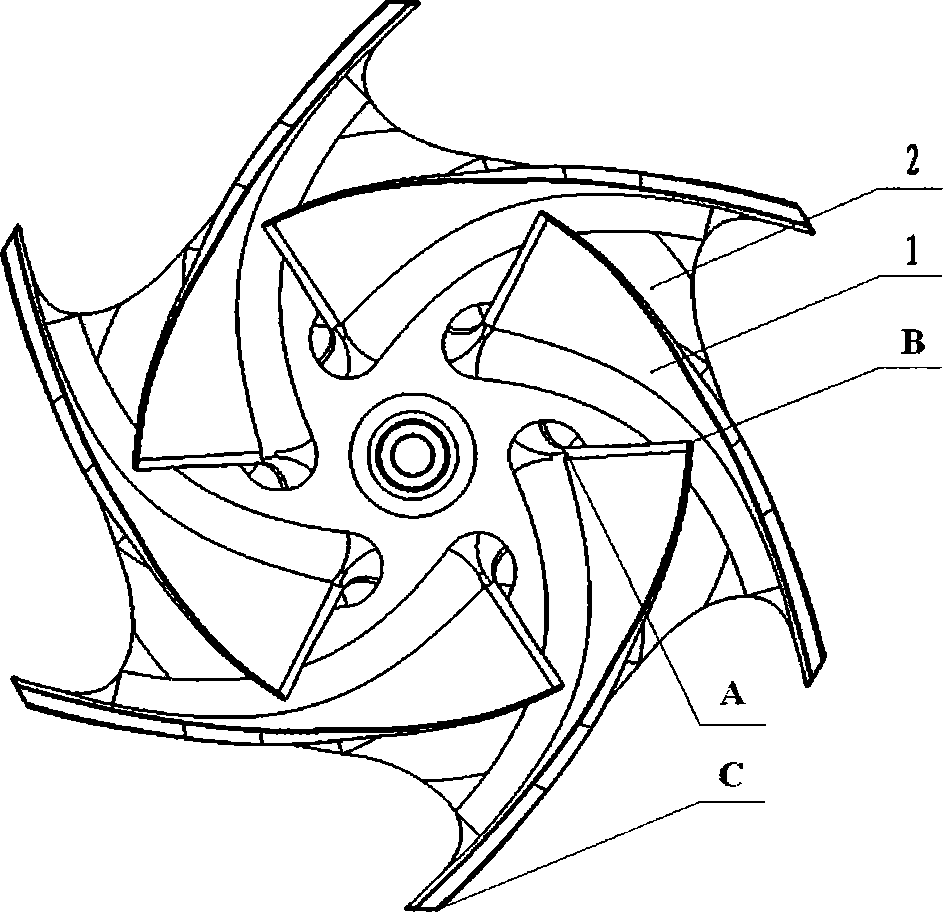

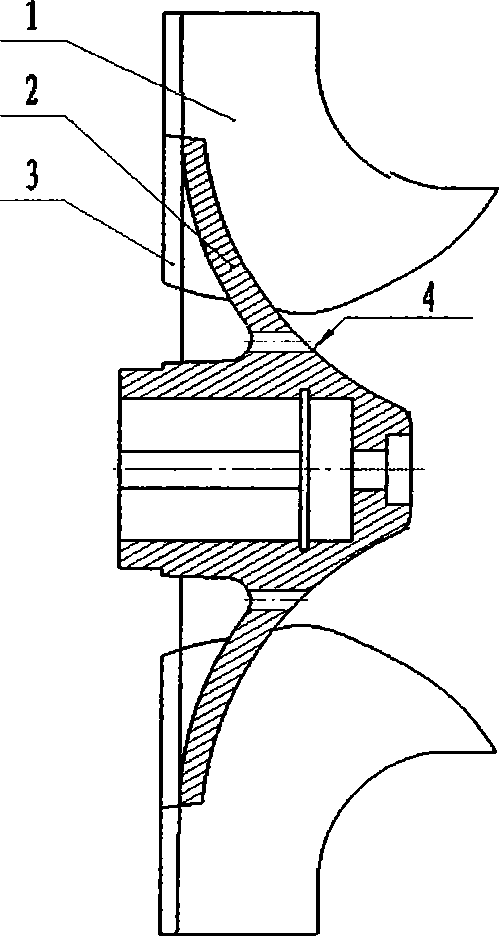

[0007] figure 1 Including impeller blade 1, rear cover plate 2, blade rear cover streamline start A, blade front cover streamline start B, and blade front cover streamline end C, it is characterized in that: impeller blade 1 utilizes Bezier (bezier) The curve control presents a greatly distorted shape. The Bezier curve is defined with four points: the starting point, the anchor point, and two separated intermediate points. Sliding the two intermediate points will cause the shape of the Bezier curve to change, reaching The maximum twist value allowed for the blade angle. The present invention designs a greatly twisted impeller blade. The twist curvature range of the blade inlet side curve AB is 90°~140°, and the twist curvature of the blade front cover streamline BC is 110°~150°. The control of the Bezier curve realizes the greatly distorted shape of the blade, so that the blade streamline reaches the optimum value in line with the law of fluid motion, which not only avoids t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com