Method for processing butterfly plate device of butterfly valve body

A butterfly valve and butterfly valve technology, which is applied in the processing field of butterfly valve body and disc device, can solve the problems of empty shaft rotation, damage and breakage, and achieve the effect of prolonging service life and reducing water leakage points and sliding pins.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

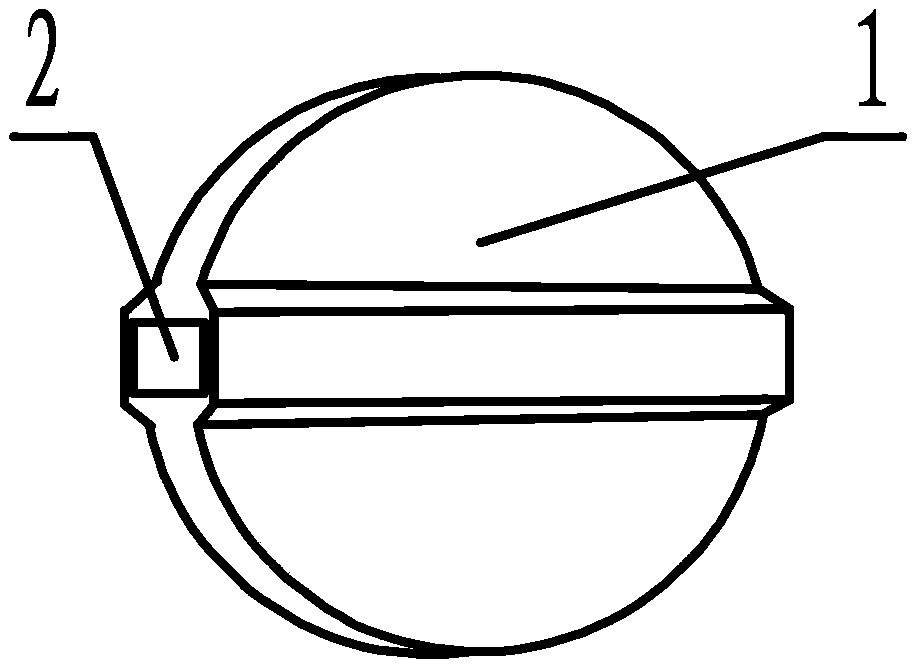

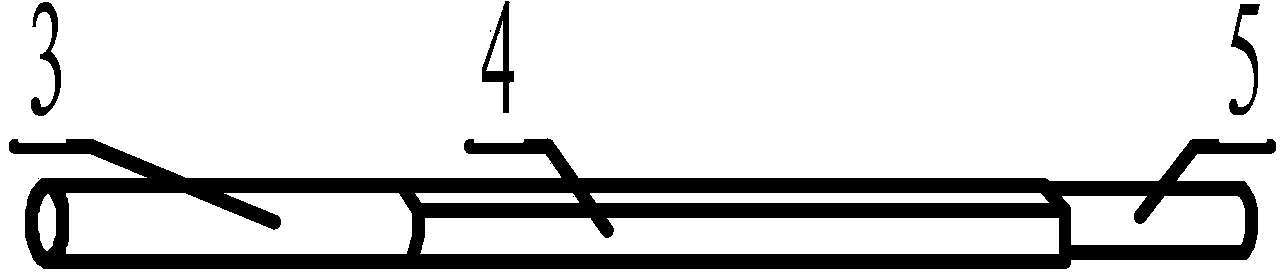

[0015] As shown in the figure; the center line of the butterfly plate 1 is provided with a radially concentric rectangular butterfly plate shaft hole 2; the connecting plate shaft section 4 is set in the rectangular butterfly plate shaft hole 2; the butterfly valve stem is coaxially set into three sections, and the main shaft section 3 The connecting plate shaft section 4 is arranged on one side, and the connecting plate shaft section 4 is rectangular.

Embodiment 2

[0017] Install the mold on the punching machine, place the original steel blank in the middle of the mold, punch it into the blank of the butterfly plate 1, take out the blank of the butterfly plate 1 from the mold, and fix the blank of the butterfly plate 1 radially on the drilling machine, and the drilling machine passes through The center line of the butterfly plate 1 radially drills a through-round hole, then removes the disc 1 with the through-round hole drilled, and fixes it radially to a milling machine, and the milling machine mills the through-round hole into a rectangular butterfly plate shaft hole 2.

Embodiment 3

[0019] The coaxial design of the butterfly valve stem is divided into three sections. On the lathe, the cylindrical steel is turned into a cylindrical main shaft section 3 and a connecting plate shaft section 4, a fixed shaft section 5, a cylindrical main shaft section 3 and a connecting plate shaft section 4 The diameter of the fixed shaft section 5 is larger than the diagonal length of the rectangle of the butterfly plate shaft hole 2; the diameter of the fixed shaft section 5 is smaller than the length of the straight side of the butterfly plate shaft hole 2 rectangle; The valve stem of the butterfly valve is fixed to the planer, and the shaft section 4 of the connecting plate is planed on the planer to make the stem of the cylindrical butterfly valve into a rectangle smaller than the shaft hole 2 of the butterfly plate; The connecting plate shaft section 4 can be installed in the butterfly plate shaft hole 2 correspondingly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com