Ultrahigh-temperature heat-insulation device

A heat insulation and heat preservation device technology, applied in the direction of heat preservation, pipeline protection through heat insulation, pipeline protection, etc., can solve the problems of not being able to play the role of heat preservation, and achieve the effect of simple structure, convenient use and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

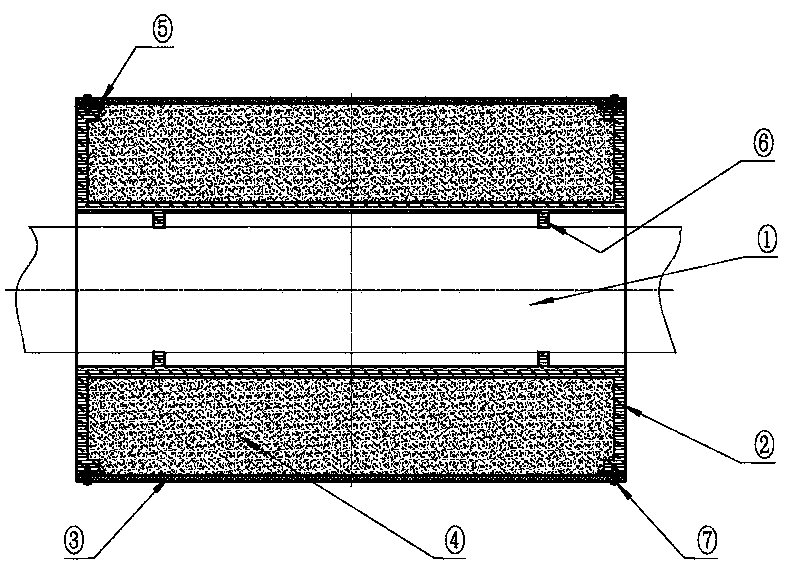

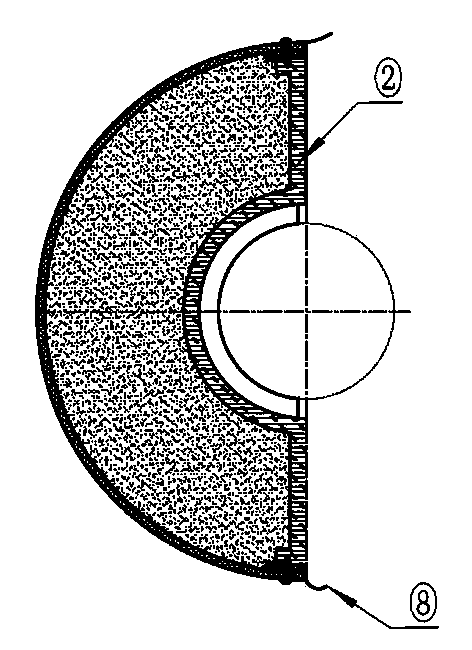

[0011] The present invention will be described in detail below in conjunction with accompanying drawing: figure 1 , 2 As shown, the thermal insulation device of the present invention is composed of a carbon-carbon material layer 2 attached to the surface of thermal equipment and pipeline 1, a high-temperature-resistant material layer 4 arranged in the middle, and an outer wall stainless steel layer 3. At least two thermal insulation pads 6 are arranged between the thermal equipment and the surface of the pipeline 1 to maintain the gap between the thermal equipment and the thermal insulation object (thermal equipment and pipeline).

[0012] The heat preservation device is composed of heat preservation blocks fixedly connected by buckles 8 or straps, and at least one section or part of the outer surface of the carbon material layer 2 of each heat preservation block is consistent with the outer surface of the thermal equipment and the pipeline 1, And an inner frame is formed, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com