Pitch-row gauge capable of being read

A technology that can be read and checked, applied in the direction of mechanical gap measurement, etc., can solve the problem of not being able to display the value, etc., and achieve the effect of simple structure and high penetration rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

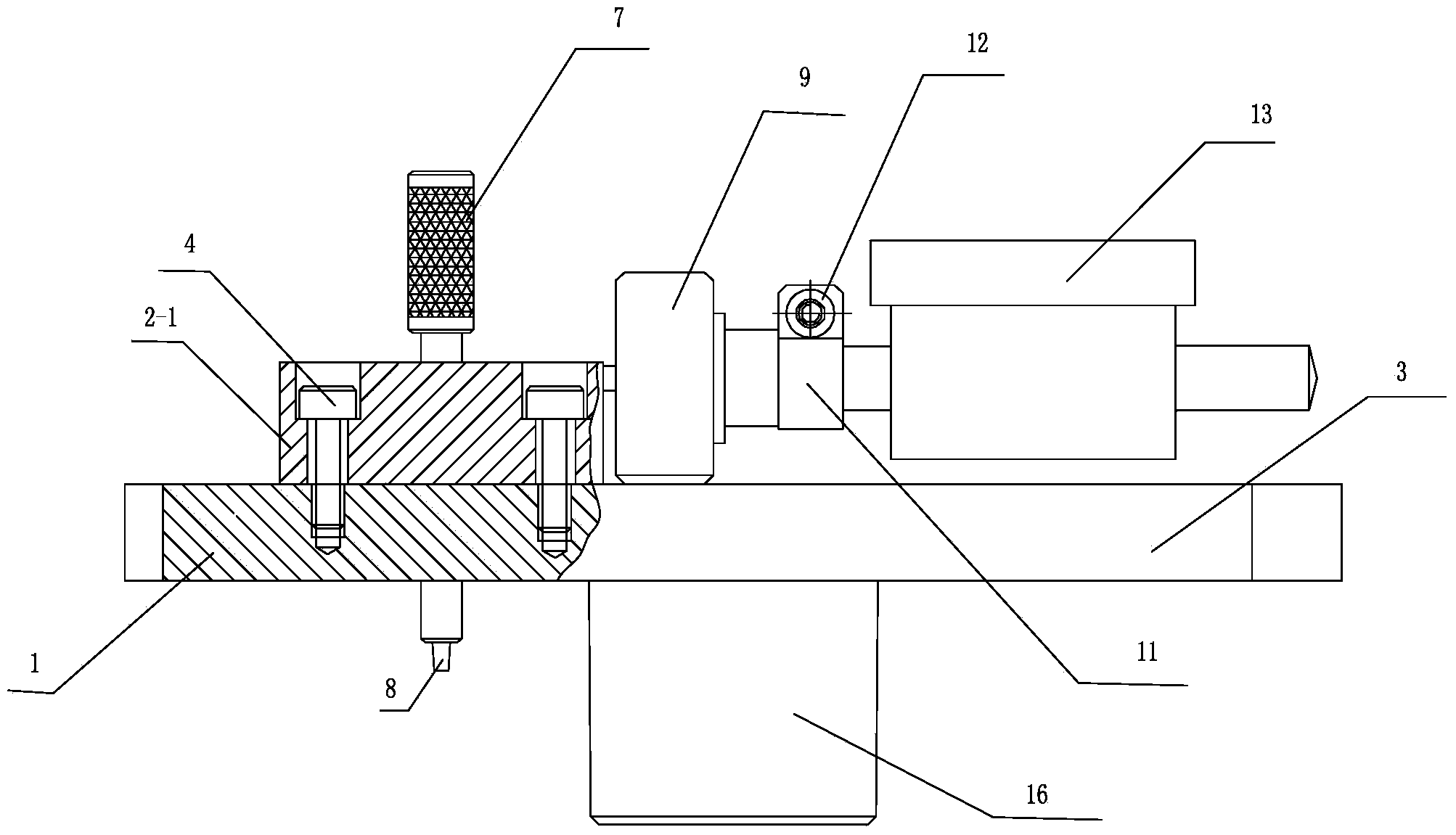

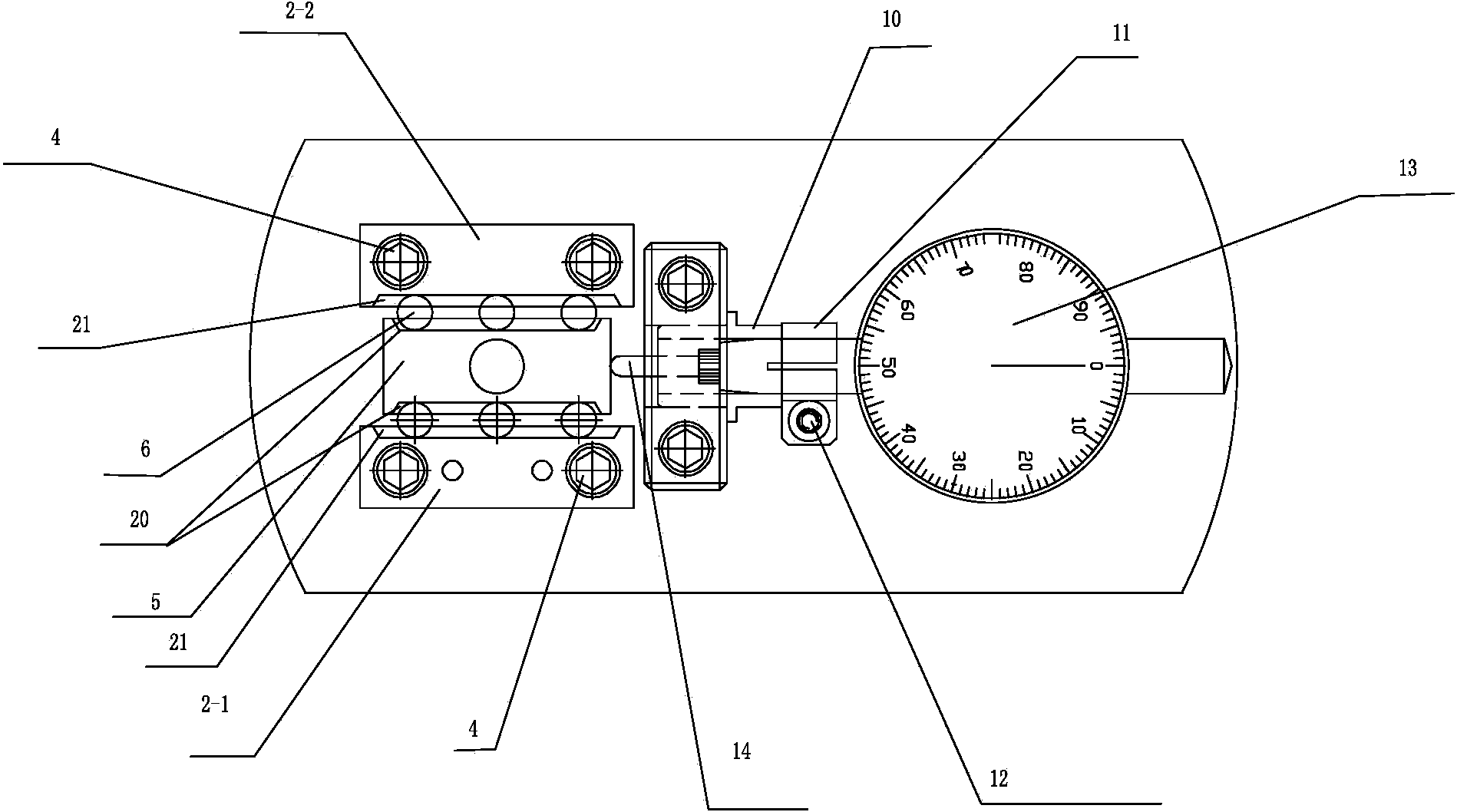

[0020] As shown in Figure-5: a readable hole distance gauge, including a gauge 3 and a calibration piece 15;

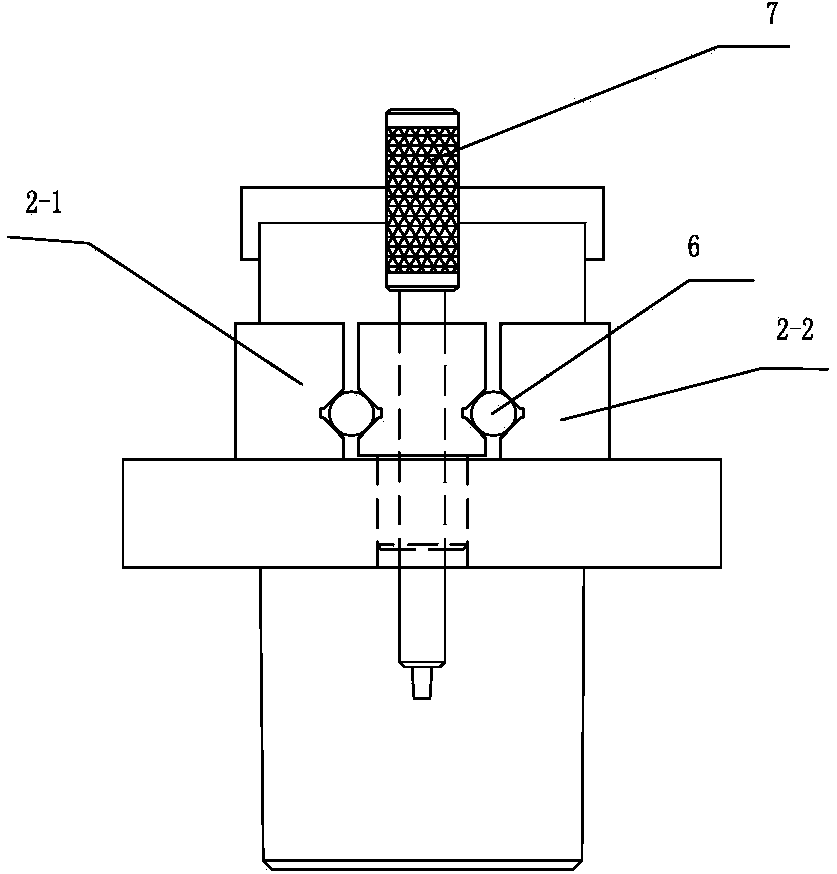

[0021] The checking tool 3 includes a checking tool main body 1, a dial indicator bracket 9 is arranged above the checking tool main body 1, and the dial indicator 13 is connected with the dial indicator bracket 9 through a fastening clip 11; the fastening clip 11 and the A spring ferrule 10 is also arranged between the dial gauge brackets 9; the dial gauge measuring head 14 of the dial gauge 13 passes through the dial gauge bracket 9 and is exposed on the inspection fixture main body 1;

[0022] There is also a sliding block 5 arranged above the main body 1 of the inspection tool, the sliding block 5 faces the dial gauge measuring head 14, is located at the front end of the dial gauge measuring head 14, and is parallel to the axial direction of the dial gauge measuring head 14; A detection pin 7 is also arranged on the sliding block 5; a first fastening block 2-1 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com