Linear guide rail precision automatic measuring device and measuring method thereof

An automatic measurement, linear guide technology, applied in the direction of measuring devices, fluid devices, instruments, etc., can solve the problems of easy wear, large workload and labor intensity, easy wear and deformation of detection plates and guide rail fixtures, and achieves a simple structure. , The effect of reducing labor intensity and reducing inspection cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

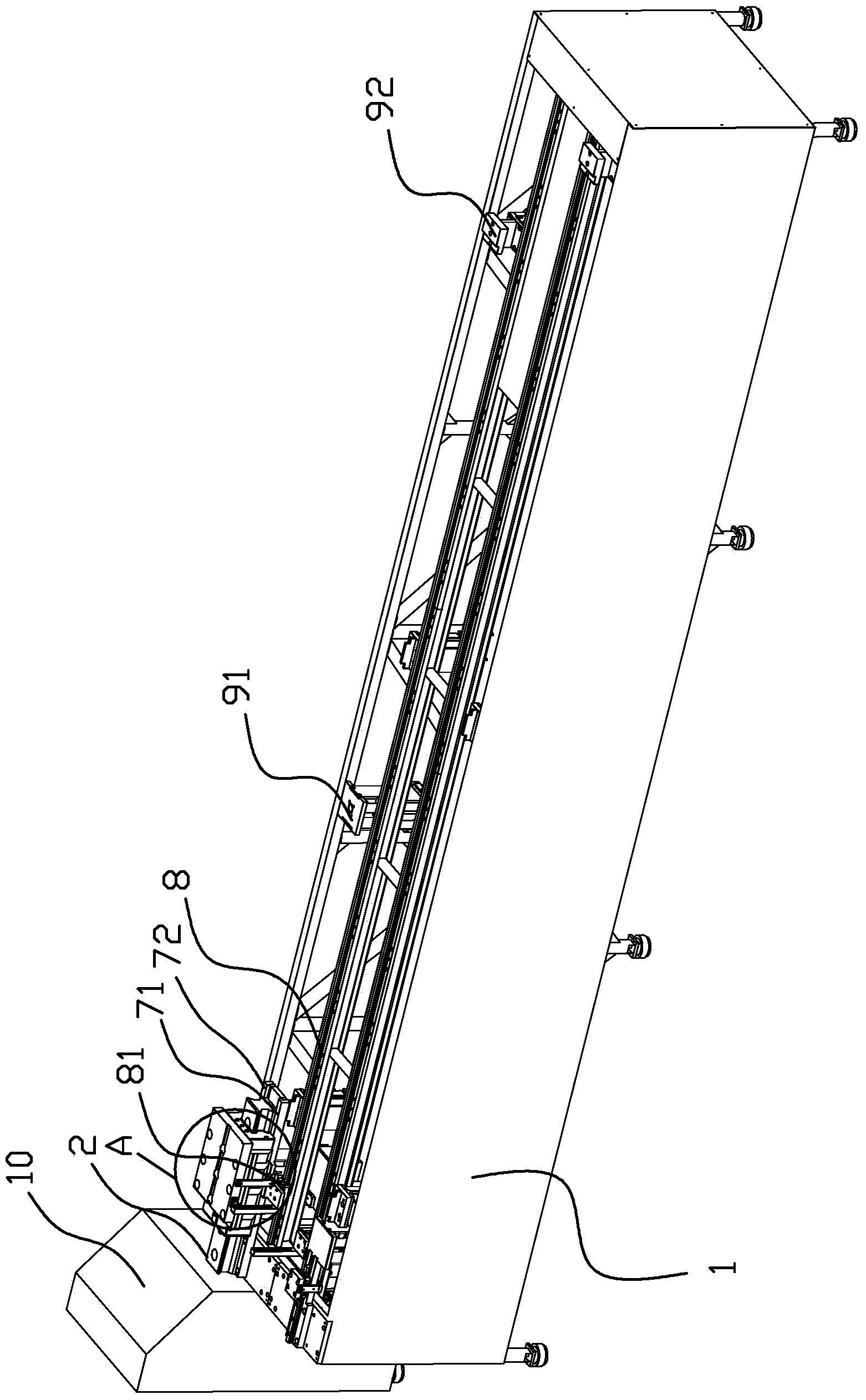

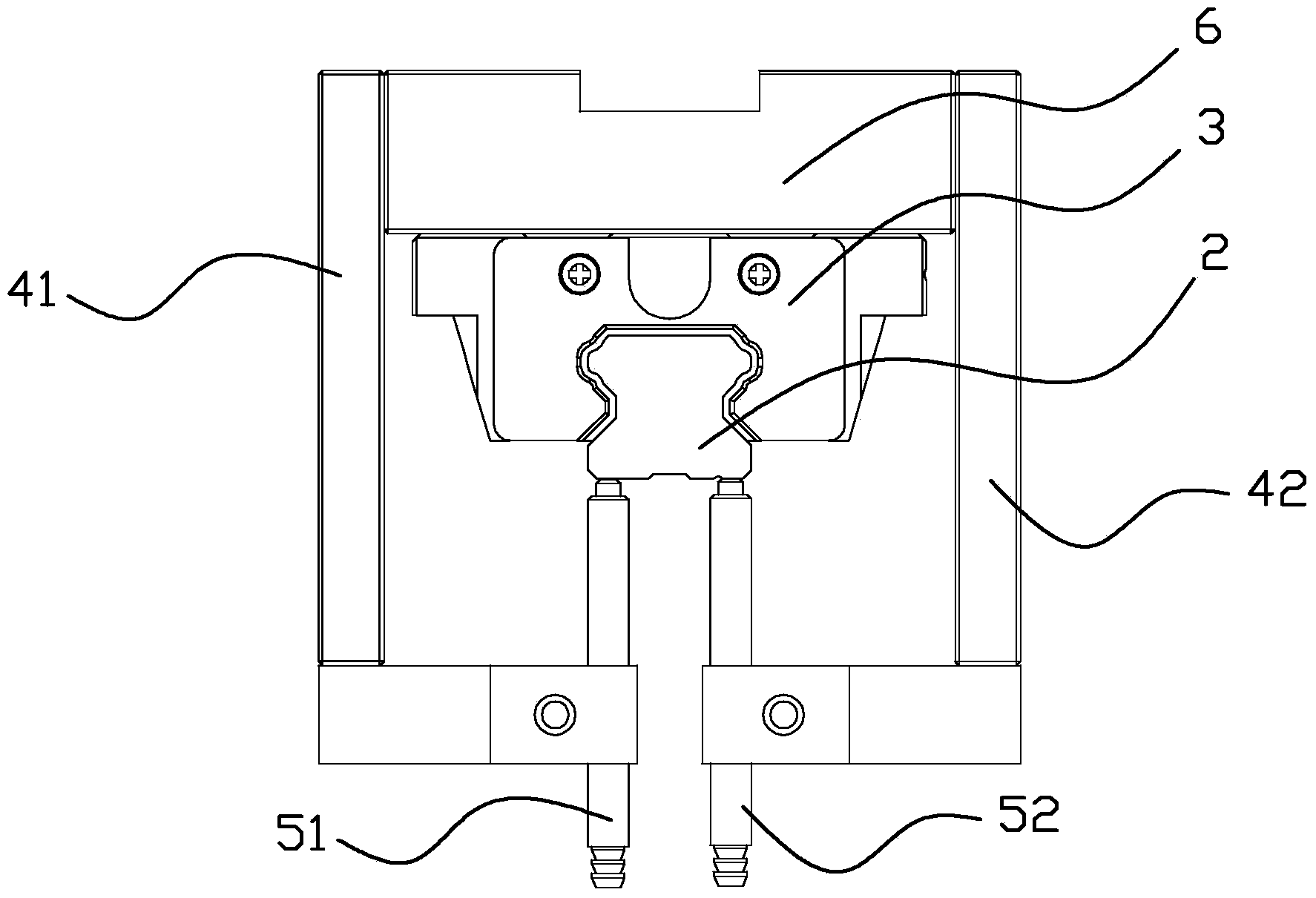

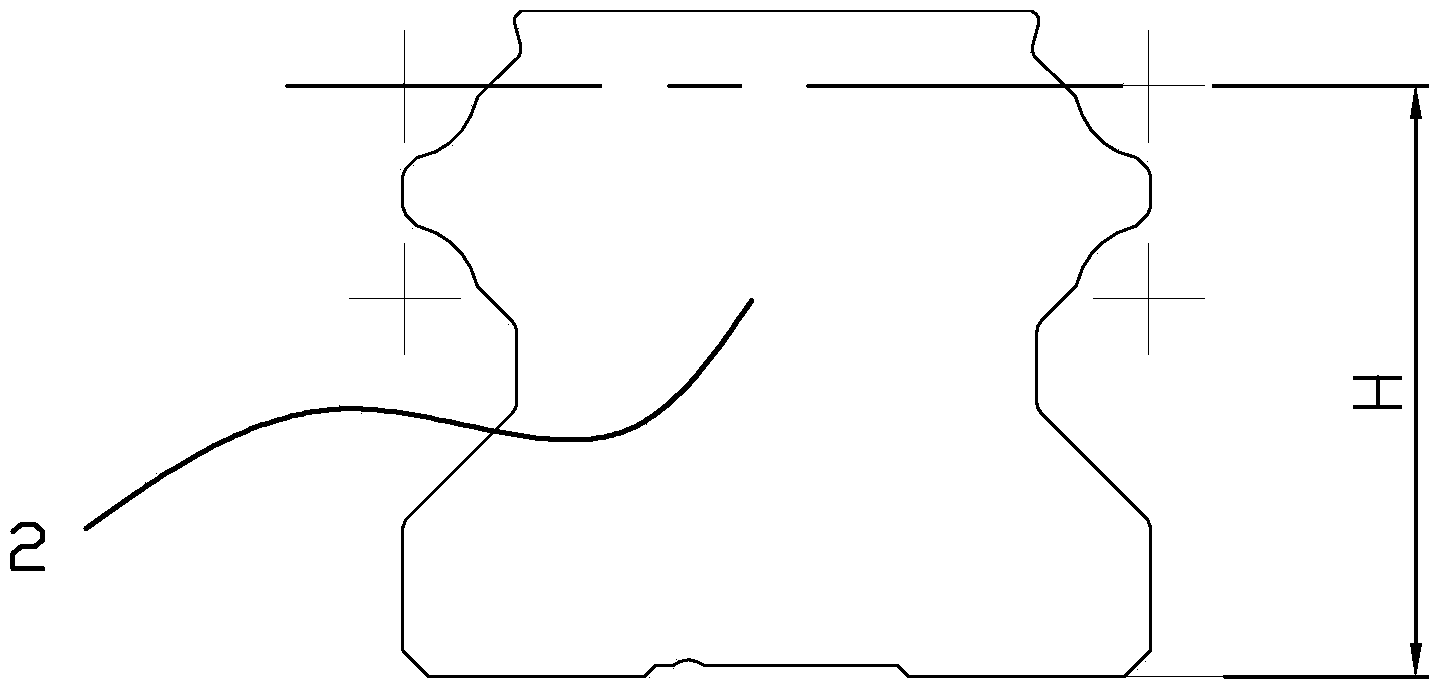

[0029] refer to figure 1 , figure 2 , a linear guide rail accuracy automatic measuring device, which includes a frame 1, a standard guide rail 2 is fixedly installed at one end of the frame 1, a reference slider 3 is inserted on the standard guide rail 2, and a top plate 6 is fixedly installed on the reference slider 3 , the both sides of top plate 6 width direction are provided with L-shaped support 41,42 respectively, and the non-contact measuring head 51,52 that is vertically arranged is fixedly installed on described two L-shaped support 41,42 respectively, and described non-contact type The probes 51 and 52 are pneumatic probes, and the two non-contact probes 51 and 52 respectively correspond to the left and right positions of the width direction of the bottom surface of the guide rail 2. The rack 1 is provided with an auxiliary tool parallel to the position of the standard guide rail 2. The guide rail 8 and the auxiliary guide rail 8 are provided with a movable sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com