Axial follow-up space loading device

A technology of follow-up loading and vertical loading, applied in measuring devices, vibration tests, instruments, etc., can solve the problems of high price and inconsistent engineering actual state, and achieve low cost, ensure flexibility and accuracy, and reliable installation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

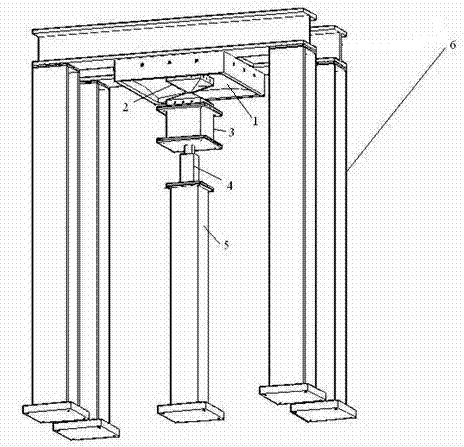

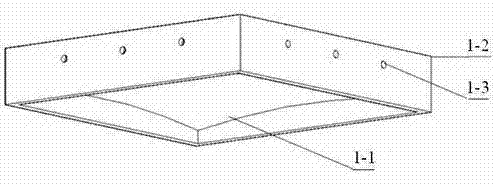

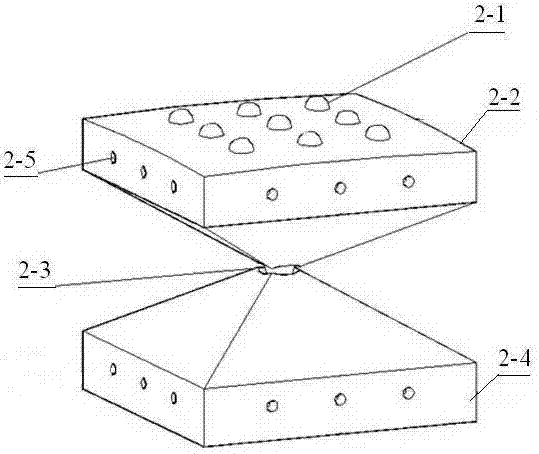

[0022] From figure 1 It can be seen that a spatial axial follow-up loading device includes a reaction force bracket 6, a vertical loader 4, a structural member 5, a reaction force pressing plate 1, a ball joint 2, a buttress 3, and the like. The reaction support 4 composed of columns and beams is fixed on the ground, or assembled and connected with the experimental platform by bolts. The counterforce pressing plate 1 is fixedly connected to the lower part of the crossbeam of the counterforce bracket 6 . The lower connecting body 2-4 of the ball joint 2 is fixedly installed on the pier 3; the lower part of the pier 3 is fixedly connected to the vertical loader 4, and the vertical loader 4 is fixedly connected to the top of the structural member 5 placed on the ground . The vertical loader 4 can be a jack or an electro-hydraulic servo actuator or the like. The vertical loader 4 is the power source for the loading system. It applies vertical loads to the structural members 5 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com