Photoelectric encoder defect detection system and implementation method thereof

A photoelectric code disc and defect detection technology, applied in the direction of optical testing flaws/defects, etc., can solve the problems of low detection efficiency of photoelectric code discs, inability to meet technical requirements, high cost and other problems, and achieve ingenious design of detection devices and save movement costs. Time, wide range of effects

Active Publication Date: 2013-12-11

UNIV OF ELECTRONICS SCI & TECH OF CHINA

View PDF11 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The purpose of the present invention is to provide a photoelectric code disk defect detection system and its implementation method, which mainly solves the problems of low detection efficiency, high false detection rate and high cost expenditure of the photoelectric code disk in the prior art, which cannot meet the technical requirements. question

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

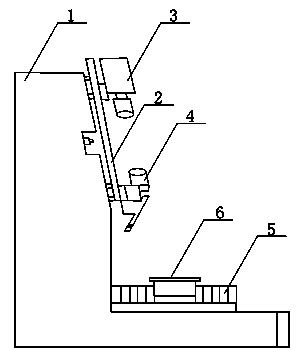

[0029] Such as figure 1 As shown, the present invention provides a photoelectric code disk defect detection system, which mainly includes a detection device for collecting images of the photoelectric code disk, and a data processing center for image processing and defect determination.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a photoelectric encoder defect detection system and an implementation method thereof and aims to solve the problems in the prior art that the detection efficiency of a photoelectric encoder is low, the false drop rate is high, the cost is high and the technical demand cannot be met. The photoelectric encoder defect detection system comprises a data processing center, and a detection device and a motor which are connected with the data processing center, wherein the detection device comprises an L-shaped mounting seat consisting of a transverse mounting seat and a longitudinal mounting seat connected with the transverse mounting seat; an X-axis moving platform which can move along the horizontal direction and is connected with the motor is arranged on the longitudinal mounting seat; a camera and a lens positioned below the camera are arranged on the X-axis moving platform; a Y-axis moving platform which can move along the vertical direction and is connected with the motor is arranged on the transverse mounting seat; an objective table is arranged on the Y-axis moving platform. According to the scheme, the aims of high performance cost ratio, high efficiency and accuracy are fulfilled, and the photoelectric encoder defect detection system has extremely high practicability and popularization values.

Description

technical field [0001] The invention relates to a defect detection system, in particular to a photoelectric code disk defect detection system and its realization method. Background technique [0002] The photoelectric code disc is made of optical glass, engraved with many concentric code tracks, and each code track has light-transmitting and opaque parts arranged according to certain rules. Since the photoelectric code disc is an important part of many sensors and automatic control systems, it can be used to measure displacement, speed, acceleration, etc., and it has the characteristics of high precision, small size, light weight and fast response. , servo transmission technology, automatic control technology, etc. are widely used. However, the existence of defective products will greatly affect its use effect, so the detection of defective products is particularly important. Traditional manual detection has low efficiency and false detection. However, due to the disadvant...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01N21/88

Inventor 刘霖赵津刘平倪光明刘娟秀杨先明陈镇龙罗颖宋昀岑

Owner UNIV OF ELECTRONICS SCI & TECH OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com