Infrared nondestructive testing method based on thermal image time sequence characteristics

An infrared non-destructive testing and timing technology, applied in the direction of optical testing flaws/defects, etc., can solve the problems of poor recognition effect of single image processing and lack of feature information, and achieve the effect of accurate effect, wide detection range and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention includes the following steps:

[0029] 1. Infrared time series heat map collection

[0030] First, use a thermal excitation source 10cm away from the specimen to heat the defective surface of the specimen for 20 minutes; secondly, the infrared thermal imager is used to automatically collect the infrared time series heat map of the specimen during the cooling process, with an interval of 30s.

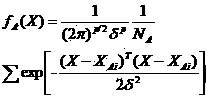

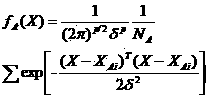

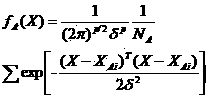

[0031] The gray level of the infrared heat map directly reflects the temperature and its distribution characteristics. Therefore, the greater the temperature difference, the greater the contrast of the image, the more conducive to identifying the target. A pixel on the thermal image Gray value at f(i,j) And the temperature value T(i,j) The following relationships exist:

[0032]

[0033] Where f(i,j) Is a grayscale image, T(i,j) Is the thermal field of the image, T Is the highest temperature of the infrared thermal image, T Is the lowest temperature of the inf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com