Coplanar capacitor type polymer molecular orientation measuring device and method

A molecular orientation and measurement device technology, applied in the direction of material capacitance, etc., can solve the problems of polymers with specific shapes and molecular orientation measurement difficulties, etc., and achieve non-destructive on-line detection, high accuracy of electrical signals, and high precision Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

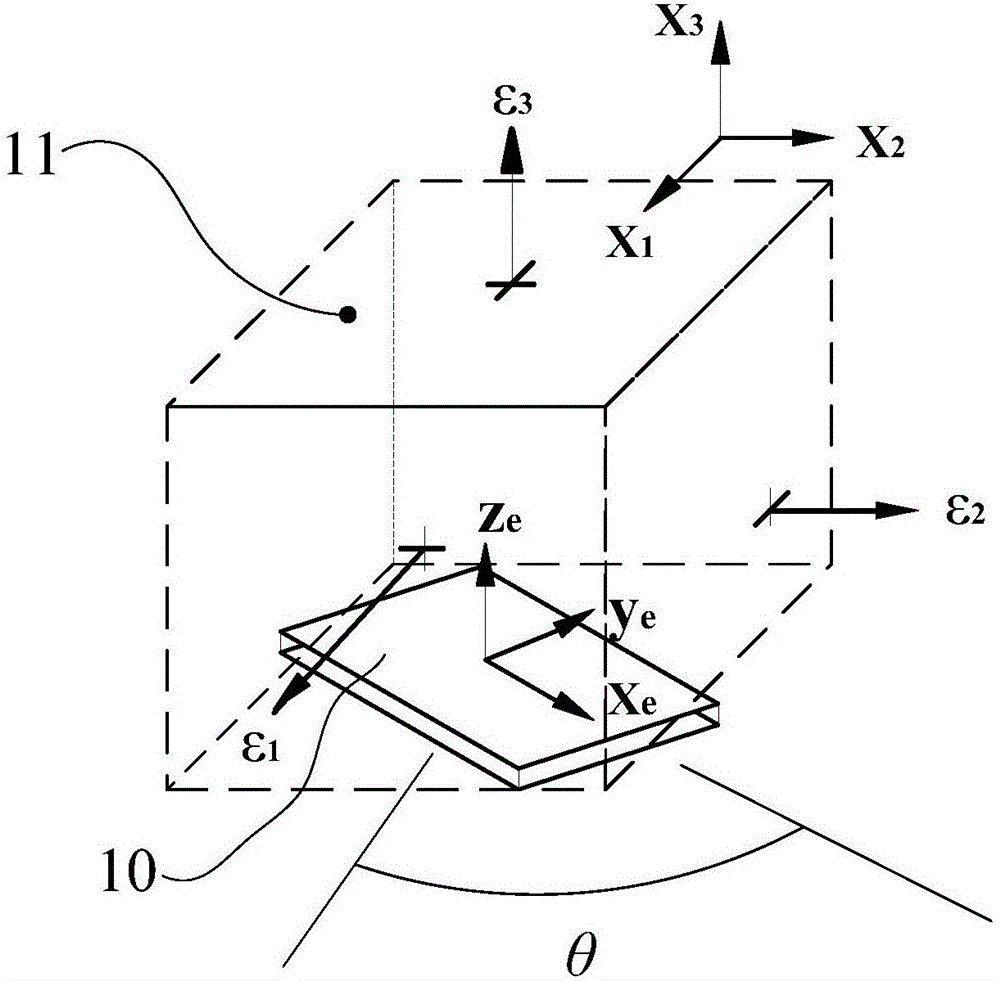

[0082] refer to Figure 5 , In this example, a rotational rheometer is used to obtain the oscillating shear flow of the polymer melt, so the orientation of the polymer molecules is roughly consistent with the flow direction of the polymer melt. In this example, the polymer material is PS (polystyrene), the rheometer is the dynamic rotational rheometer of the American TA company, the instrument model is AR-1000, and the concentric cylindrical pressure sensor is used, wherein the outer cylinder 16 is fixed, and the radius R 2 =22.5mm, inner cylinder 15 rotates with the rheometer, radius R 1 = 21 mm. The PS melt is between two cylindrical surfaces. Since the gap between the two cylinders is much smaller than the radius of the two cylinders, it can be approximated as a pure shearing motion.

[0083] The specific orientation measurement method steps include:

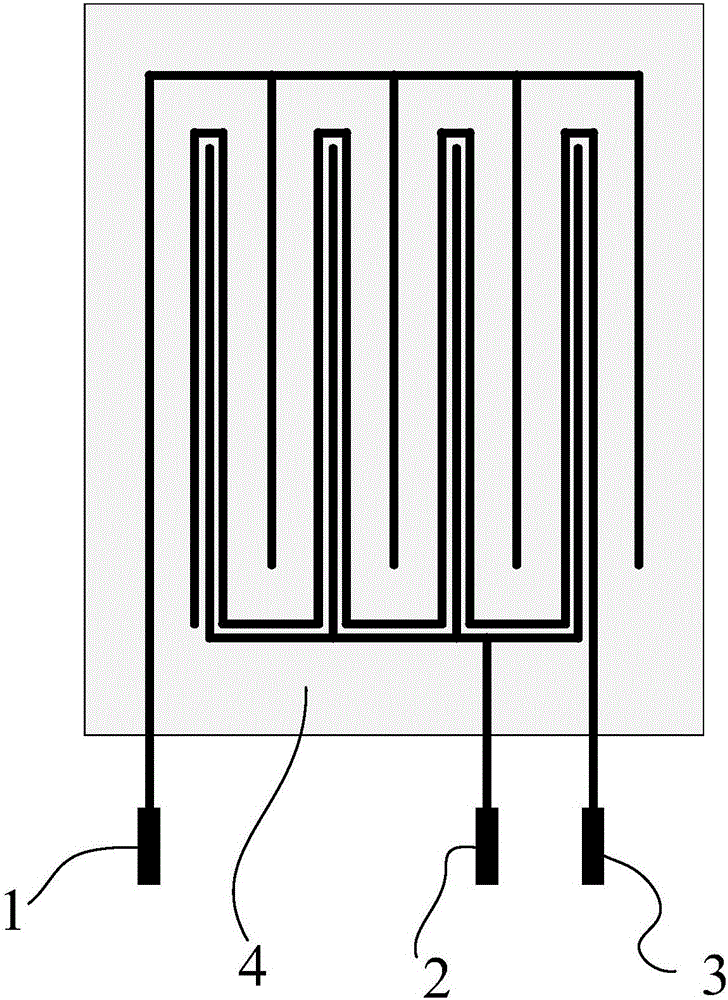

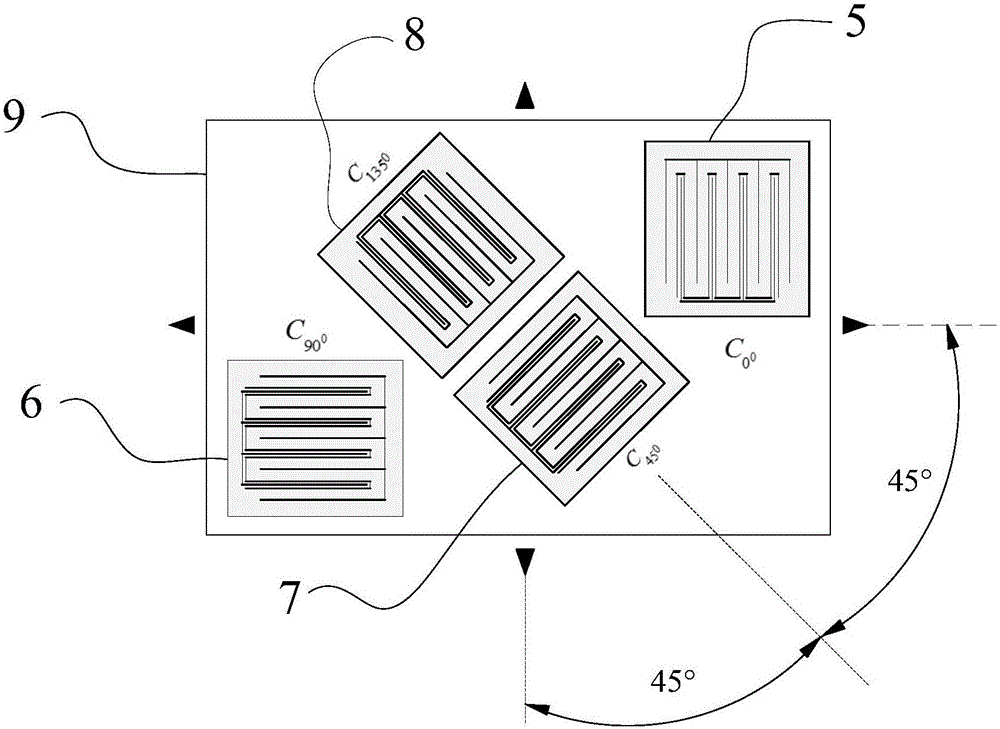

[0084] 1) At least one coplanar capacitive orientation measurement sensor probe array is installed on the inner surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com