Polarizing microscopic image automatic acquisition and analysis device

A technology of automatic collection and polarized light microscopy, applied in microscopes, material analysis through optical means, measuring devices, etc., can solve the problems of not being able to observe various mineral changes at the same position, mineral tracking errors, inconvenient identification statistics, etc., to achieve Avoid mineral color change tracking errors, ensure consistency, and facilitate analysis and processing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with accompanying drawing:

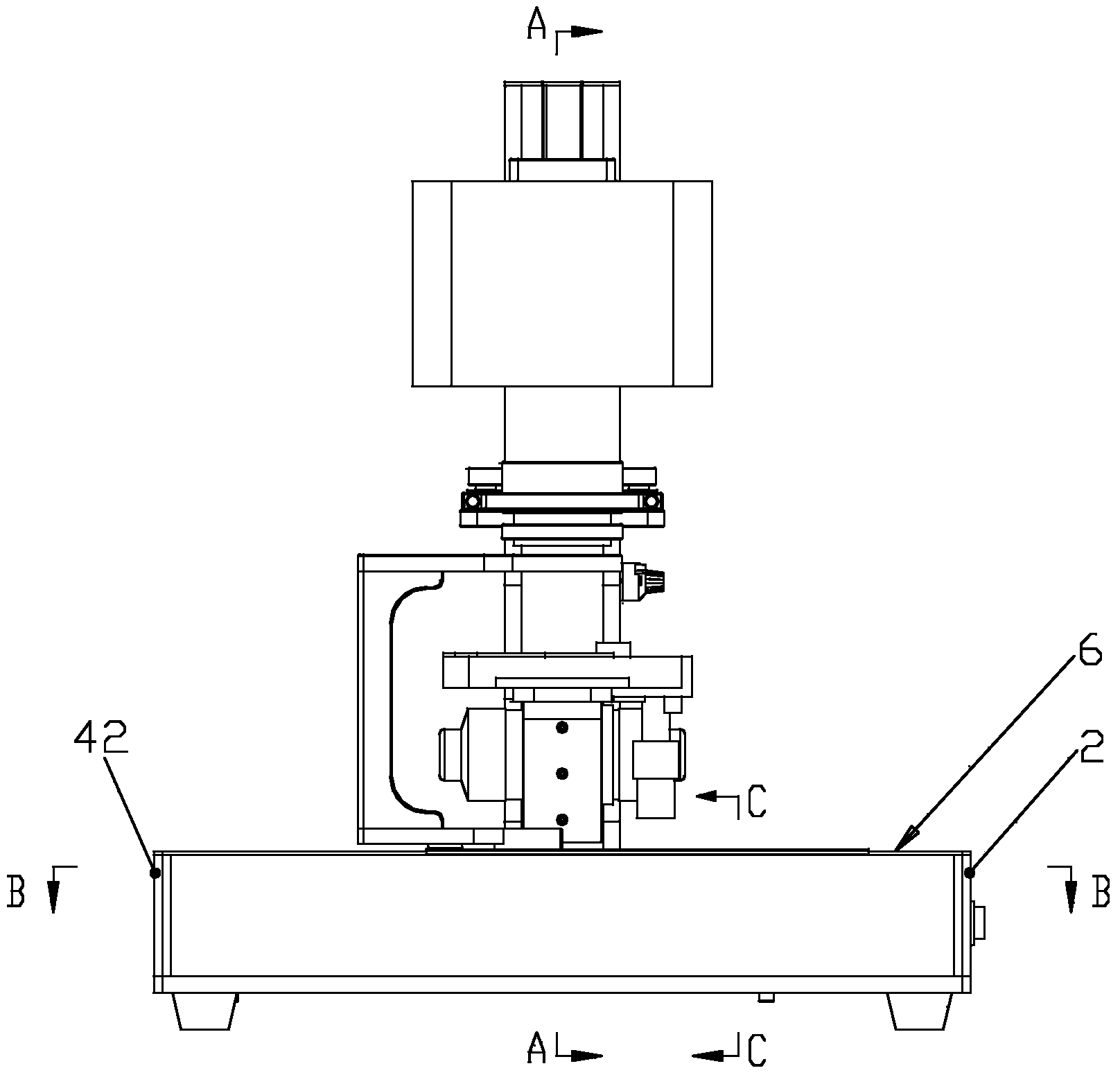

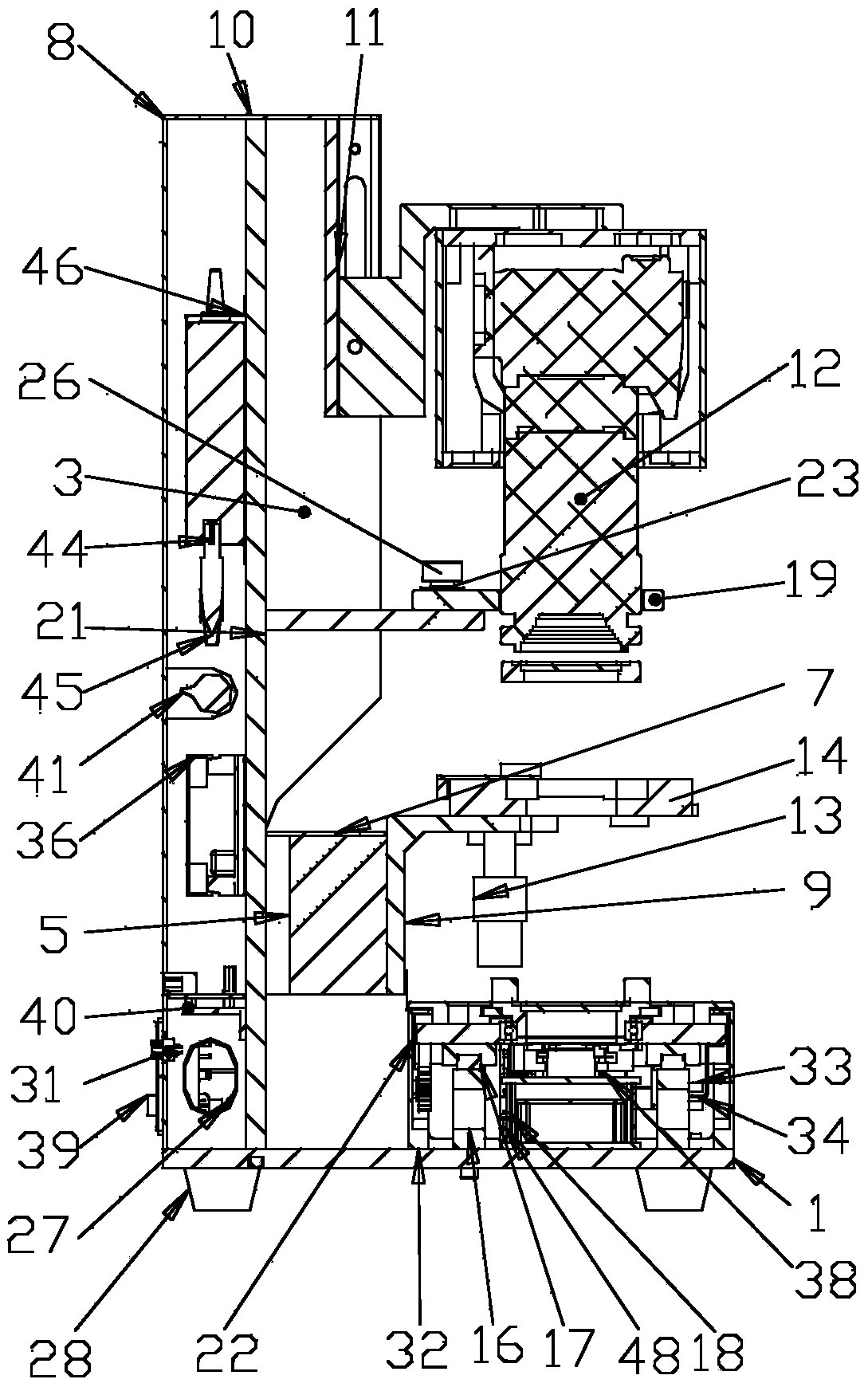

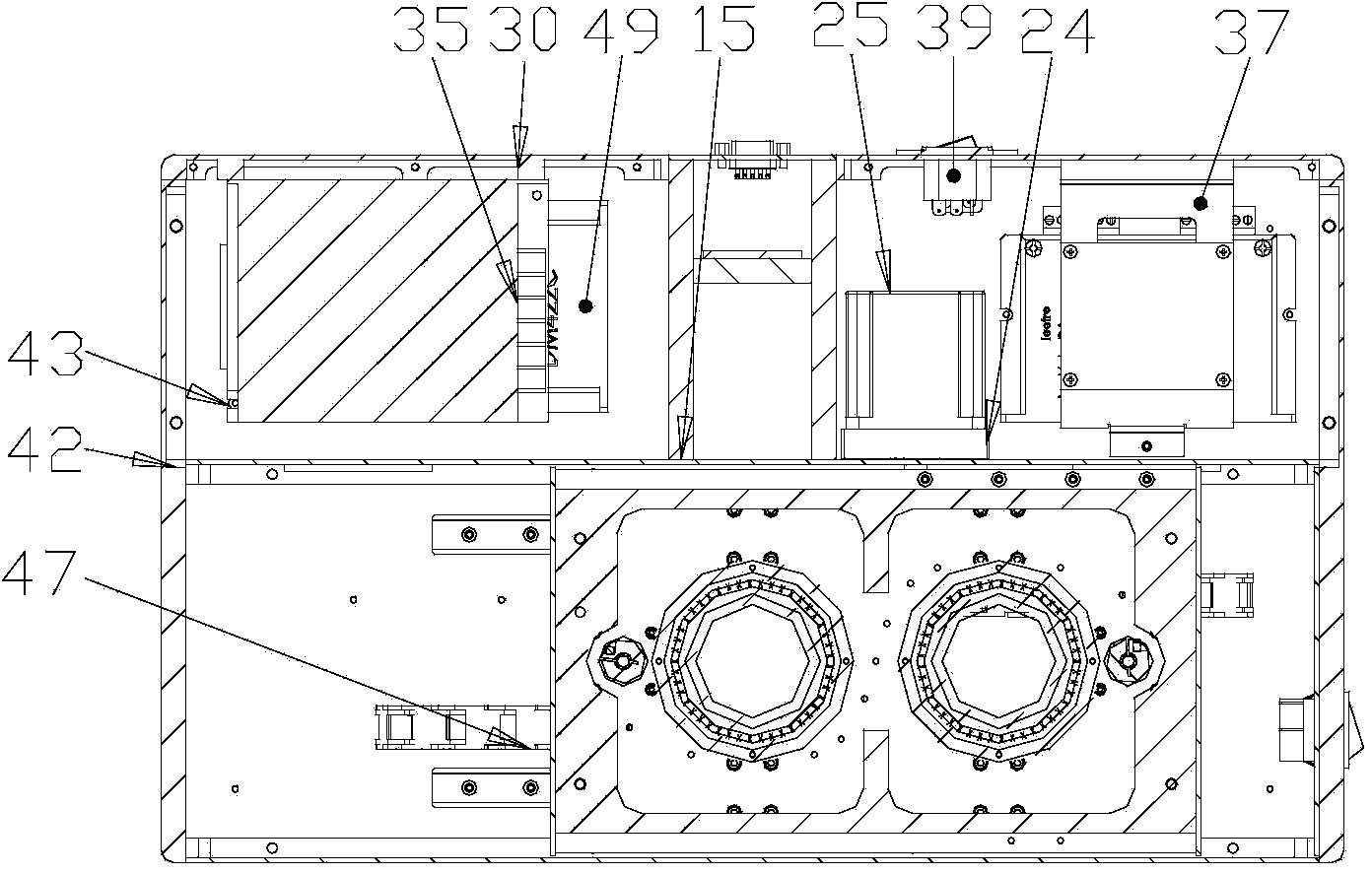

[0035] Such as Figure 1 to Figure 6As shown, the polarizing microscopic image automatic acquisition and analysis device of the present invention includes a main support, a substrate 1, four rubber feet 28, an object stage, a control board assembly 37, a mobile slide assembly, a camera assembly and a light source assembly 18 , four rubber feet 28 are respectively arranged on the four corners of the substrate 1, the lower end of the main bracket is fixedly connected with the substrate 1, and the moving slide assembly includes a lower polarizer seat assembly, an upper polarizer seat assembly 63, a first stepping motor 25. The second stepper motor 60, the third stepper motor 77, two linear guide rails 17, two linear guide rail installation beams 16 and four guide rail sliders 61, the lower end of the linear guide rail installation beams 16 is fixedly installed on the base plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com