Circuit board soldering fixture

A technology for welding jigs and circuit boards, which is applied in the direction of assembling printed circuits with electrical components, and can solve problems such as short circuits, affecting circuit board functions, and poor appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

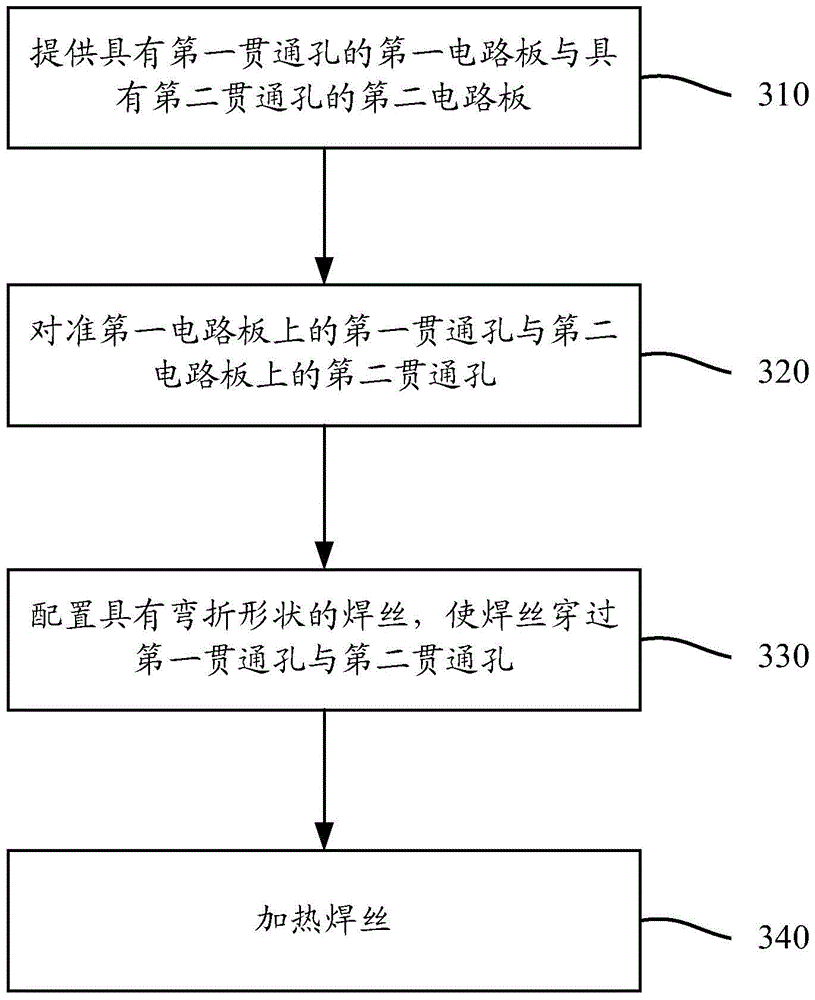

[0033] The following will clearly illustrate the spirit of the present invention with illustrations and detailed descriptions. Those of ordinary skill in the art, after understanding the preferred embodiments of the present invention, can make changes and modifications based on the techniques taught in the present invention. without departing from the spirit and scope of the present invention.

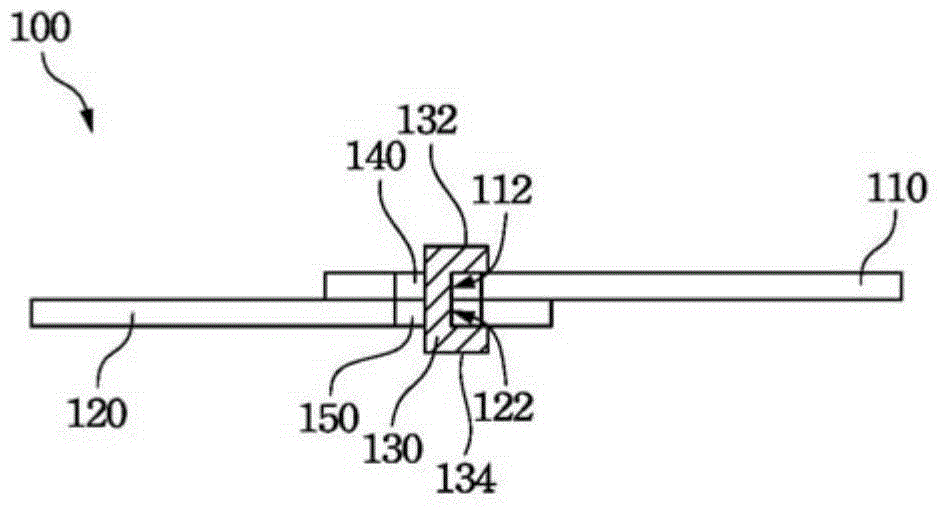

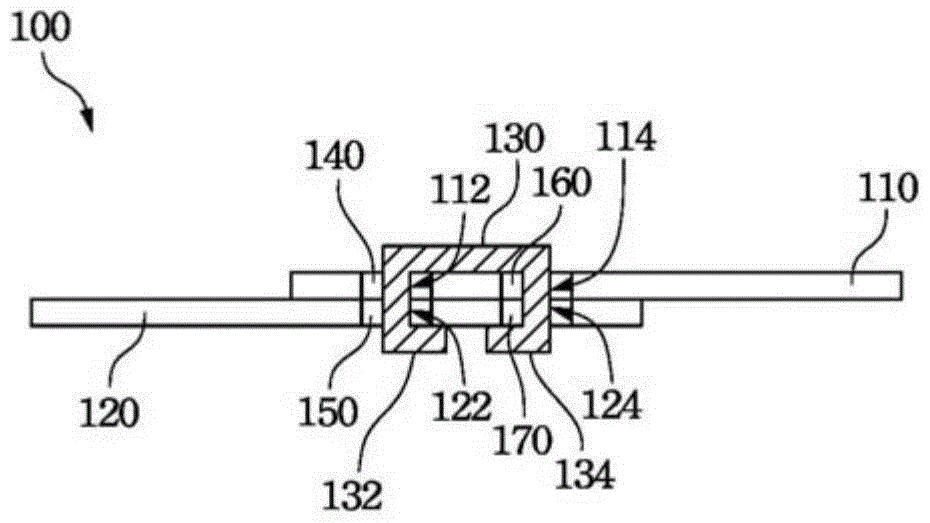

[0034] refer to figure 1 , which shows a schematic view of the first embodiment of the circuit board soldering structure using the circuit board soldering jig of the present invention. The circuit board welding structure 100 includes a first circuit board 110, a second circuit board 120, a welding wire 130 connecting the first circuit board 110 and the second circuit board 120, and a first solder joint 140 located on the first circuit board 110, And the second solder joint 150 on the second circuit board 120 . Wherein the first circuit board 110 has a first through hole 112 , and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com