Rubber composition and tire

A rubber composition, rubber technology, applied in special tires, tire parts, transportation and packaging, etc., can solve the problems of tire tread wear resistance, rolling resistance factory processability and crack resistance cannot be improved at the same time, Achieve the effect of improving factory workability and improving crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

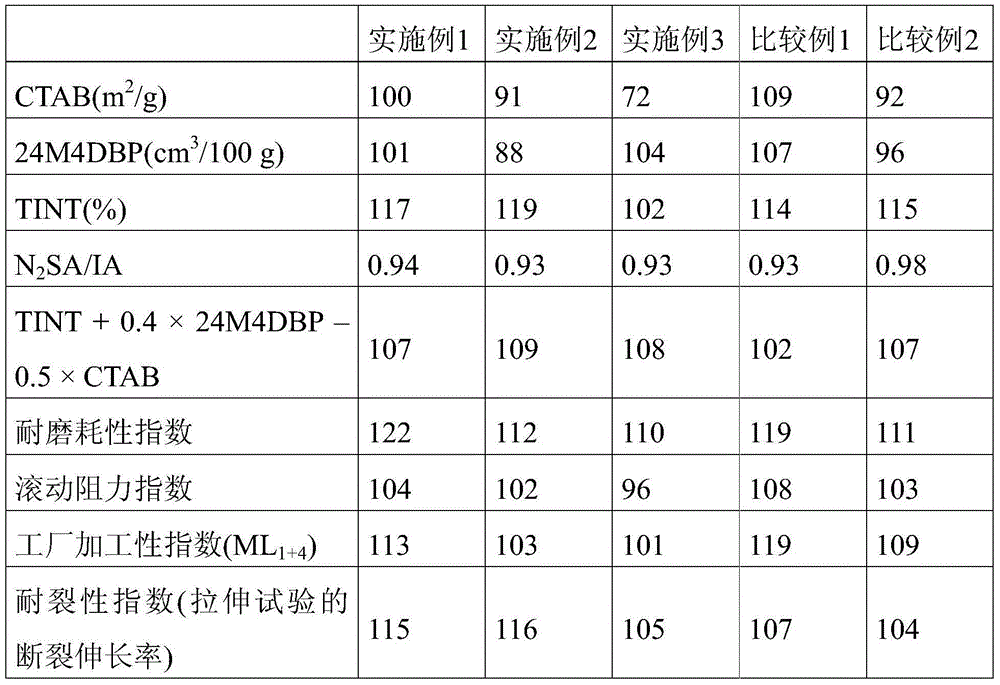

Embodiment 1 to 3 and comparative example 1 to 10

[0066] Preparation of rubber composition

[0067] The components were mixed in a Banbury mixer in the proportions listed in Table 1 below to prepare rubber compositions. Carbon black properties were measured by the following methods. In addition, carbon black was produced under the conditions listed in Table 2 by an oil furnace method of production using a furnace manufactured by Asahi Carbon Co., Ltd.

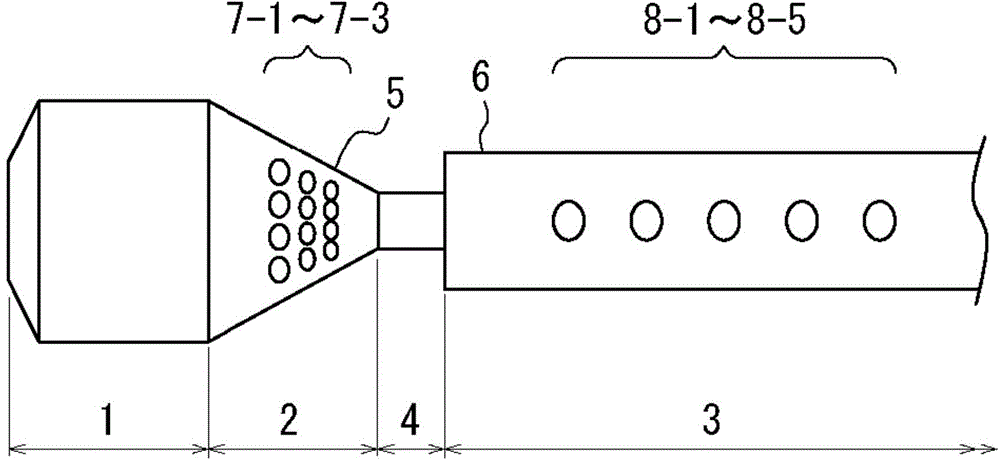

[0068] Note that this furnace is a cylindrical manufacturing device having a first zone 1 (diameter: 700 mm, length: 1000 mm) for burning fuel and air for supplying raw oil and generating carbon black The second area 2 (upstream end diameter: 700mm, downstream end diameter: 230mm, length: 1200mm), choke part 4 (diameter: 230mm, length: 400mm), and the third area (diameter: 576mm, length: 5000mm, Reaction zone diameter / choke zone diameter ratio: 2.5).

[0069] In addition, in Comparative Example 6, ASTM N330 was used as carbon black, and in Comparative Example 7, ASTM N339 w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| oil absorption value | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com