Automotive fluidic pump

A fluid pump, vehicle technology, applied in the direction of fluid clutches, clutches, mechanical equipment, etc., can solve the problems of inability to fail protection, inability to engage or connect couplings, incompatibility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

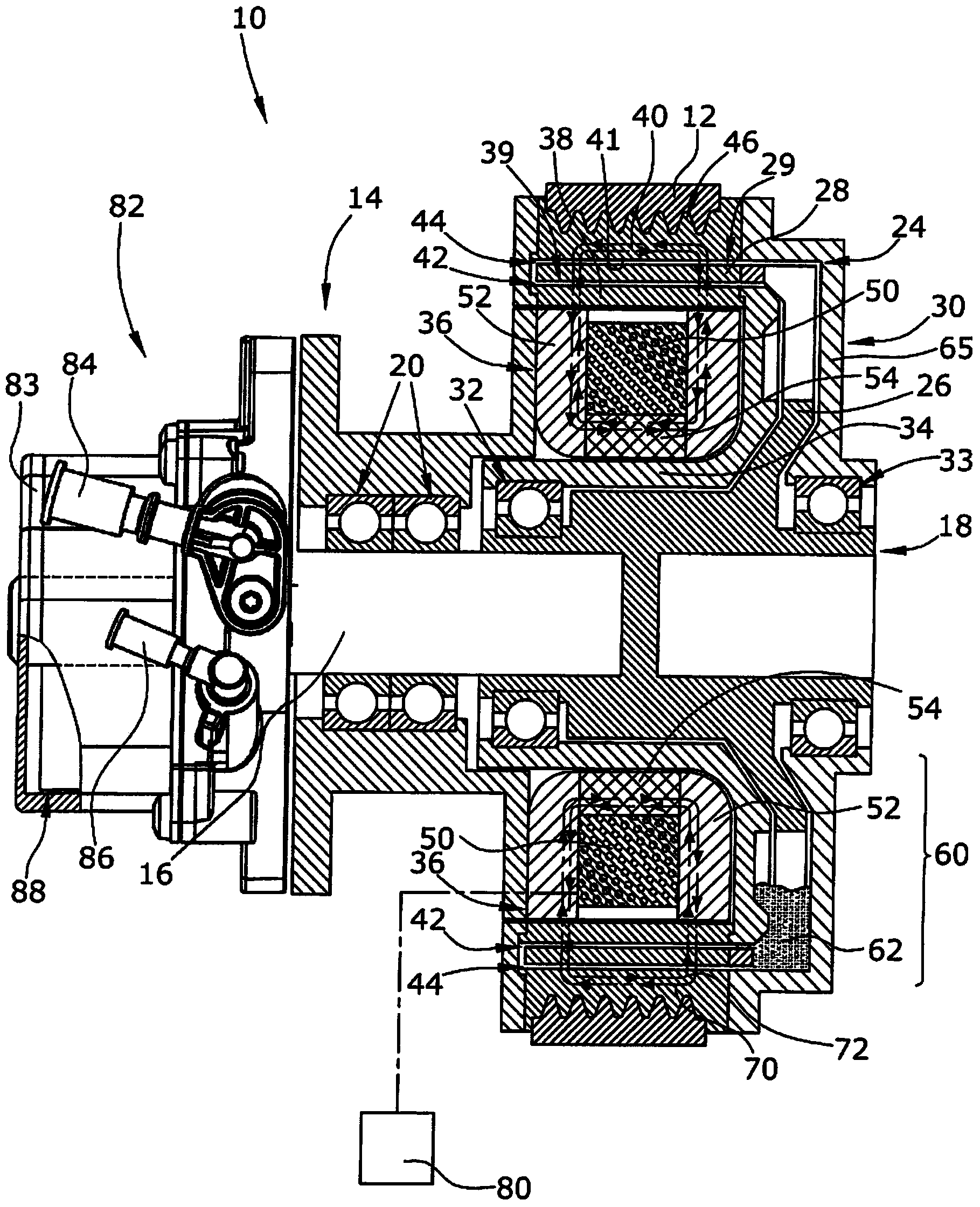

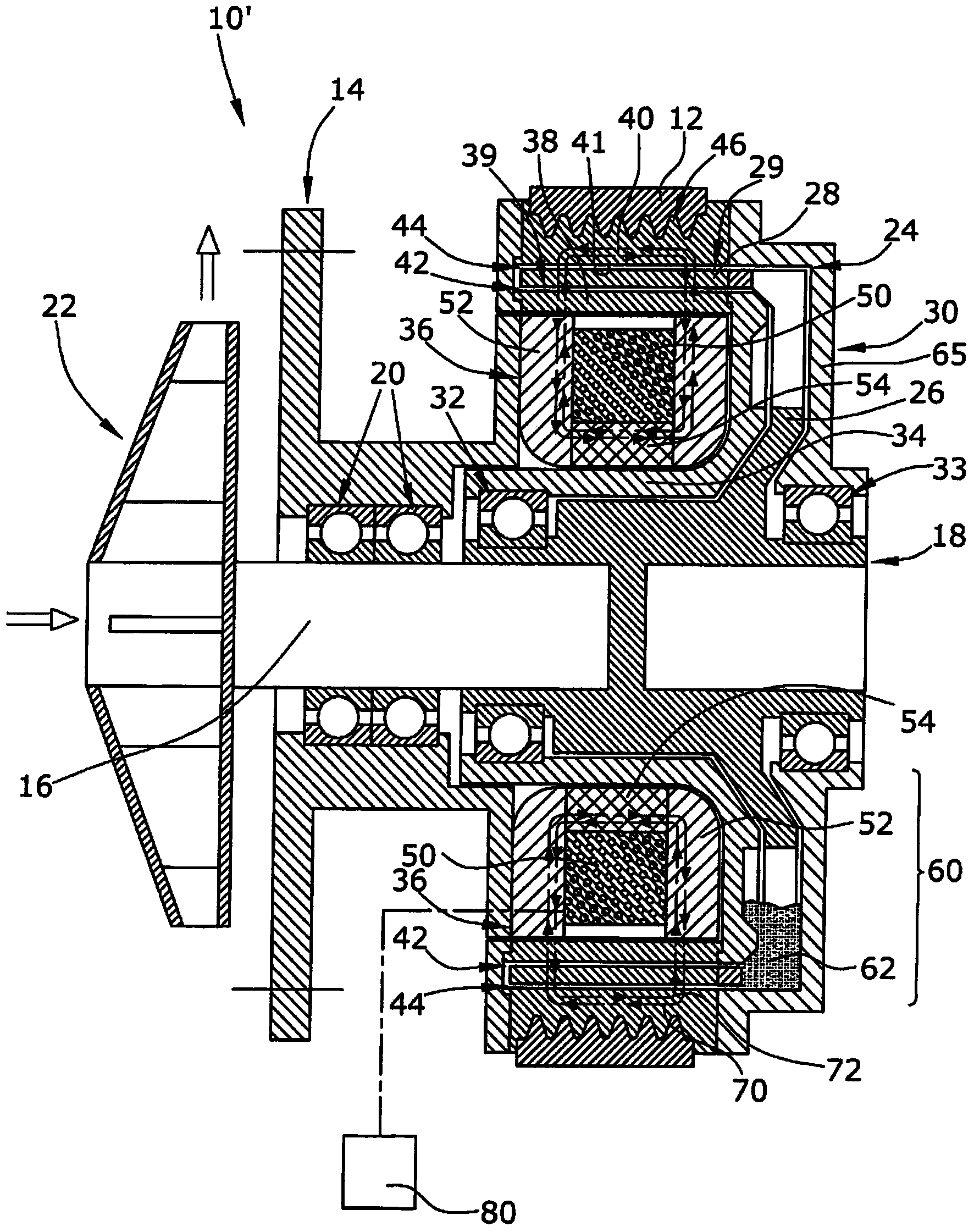

[0016] figure 1 A mechanical vehicle air pump 10 is shown, figure 2 A mechanical vehicle fluid pump 10' in the form of a coolant pump is shown. Both pumps 10, 10' are fluid pumps. The pneumatic pump 10 provides a gas, such as air, under pressure or provides vacuum to other engine components. The coolant pump 10' supplies liquid coolant to the internal combustion engine. The pumps 10, 10' are directly driven by the engine via a drive belt 12.

[0017] The pumps 10 each include a pump frame 14, 14' mountable to an engine block (not shown) of an engine. The pump frame 14, 14' supports the rotor shaft 16 of the pump rotor 18 by means of two roller bearings 20. The pump rotor 18 includes pump wheels 88 , 22 , a rotor shaft 16 and a rotatable clutch portion 24 which is permanently connected to the pump wheel 22 via the rotor shaft 16 .

[0018] The pneumatic pump 10 has a pump portion 82 including a pump housing 83 , a pump inlet 84 , a pump outlet 86 and a pump rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com