Method for preparing tea leaves by hot pepper leaves

A technology of chili leaves and tea, which is applied in the field of preparing tea from chili leaves, which can solve problems such as environmental pollution and waste of resources, and achieve the effects of improving harvest index, protecting the environment, and lingering aftertaste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

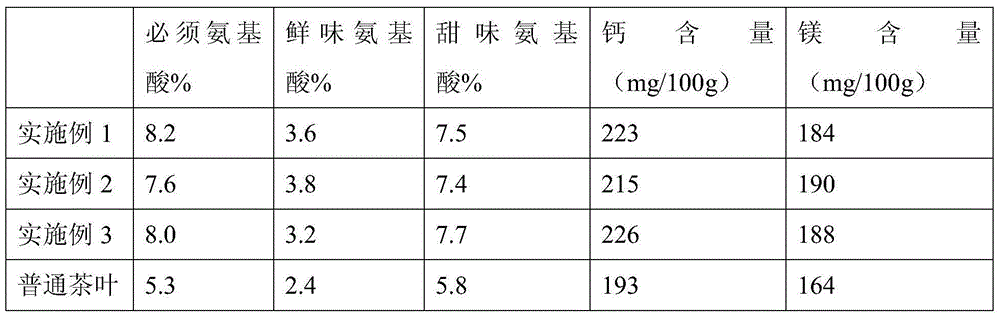

Examples

Embodiment 1

[0020] A method for preparing tea leaves from capsicum leaves, comprising the following steps:

[0021] 1) Pick fresh pepper leaves in the mature period of pepper, the leaves are free from disease, insect eyes, and not dry;

[0022] 2) Clean the pepper leaves and spread them to dry, with a thickness of 3cm, and spread them until the water content of fresh leaves is controlled at 60%;

[0023] 3) Microwave-type de-greening machine is used for de-greening, so that the de-greening leaves are soft, lose their luster, green air is lost, and the fragrance overflows, and the water content is controlled at 50%;

[0024] 4) Frying and kneading, the frying temperature is 170°C, the time is 6 minutes, and it is tanned while it is hot;

[0025] 5) Roast and enhance the fragrance until the finished product is crisp, with a moisture content of ≤6%; sterilized and packaged.

[0026] The airing time in the step 2) is 4 hours.

[0027] The finishing temperature in step 3) is controlled at 1...

Embodiment 2

[0030] A method for preparing tea leaves from capsicum leaves, comprising the following steps:

[0031] 1) Pick fresh pepper leaves in the mature period of pepper, the leaves are free from disease, insect eyes, and not dry;

[0032] 2) Clean the pepper leaves, spread them out to a thickness of 6cm, and spread them out until the water content of fresh leaves is controlled at 75%;

[0033] 3) Microwave-type de-greening machine is used for de-enzyming, and the de-enzyme leaves are soft and dull, green air is lost, and the fragrance overflows, and the water content is controlled at 62%;

[0034] 4) Frying and kneading, the frying temperature is 200°C, the time is 4 minutes, and tanned while hot;

[0035] 5) Roast and enhance the fragrance until the finished product is crisp, with a moisture content of ≤6%; sterilized and packaged.

[0036] Preferably, the airing time in step 2) is 4-10 hours.

[0037] Preferably, the killing temperature in step 3) is controlled at 200°C, and th...

Embodiment 3

[0040] A method for preparing tea leaves from capsicum leaves, comprising the following steps:

[0041] 1) Pick fresh pepper leaves in the mature period of pepper, the leaves are free from disease, insect eyes, and not dry;

[0042] 2) Clean the pepper leaves, spread them out to a thickness of 4cm, and spread them out until the water content of fresh leaves is controlled at 70%;

[0043] 3) Microwave-type de-greening machine is used for de-enzyming, and the de-greening leaves are soft and dull, green air is lost, and the fragrance overflows, and the water content is controlled at 56%;

[0044] 4) Frying and kneading, the frying temperature is 180°C, the time is 5 minutes, and tanned while hot;

[0045] 5) Roast and enhance the fragrance until the finished product is crisp, with a moisture content of ≤6%; sterilized and packaged.

[0046] The airing time in the step 2) is 7 hours.

[0047] The finishing temperature in the step 3) is controlled at 160°C, and the finishing tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com