Method for freezing automatic sequencing rolling pass of plate of moderate thickness

An automatic program and rolling pass technology, applied in metal rolling, metal rolling, rolling mill control devices, etc., can solve the problems of roll equipment safety hazards, bending, edge wave shape, etc., to improve the quality of the plate shape , Reduce the rolling pass, the best pass rolling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

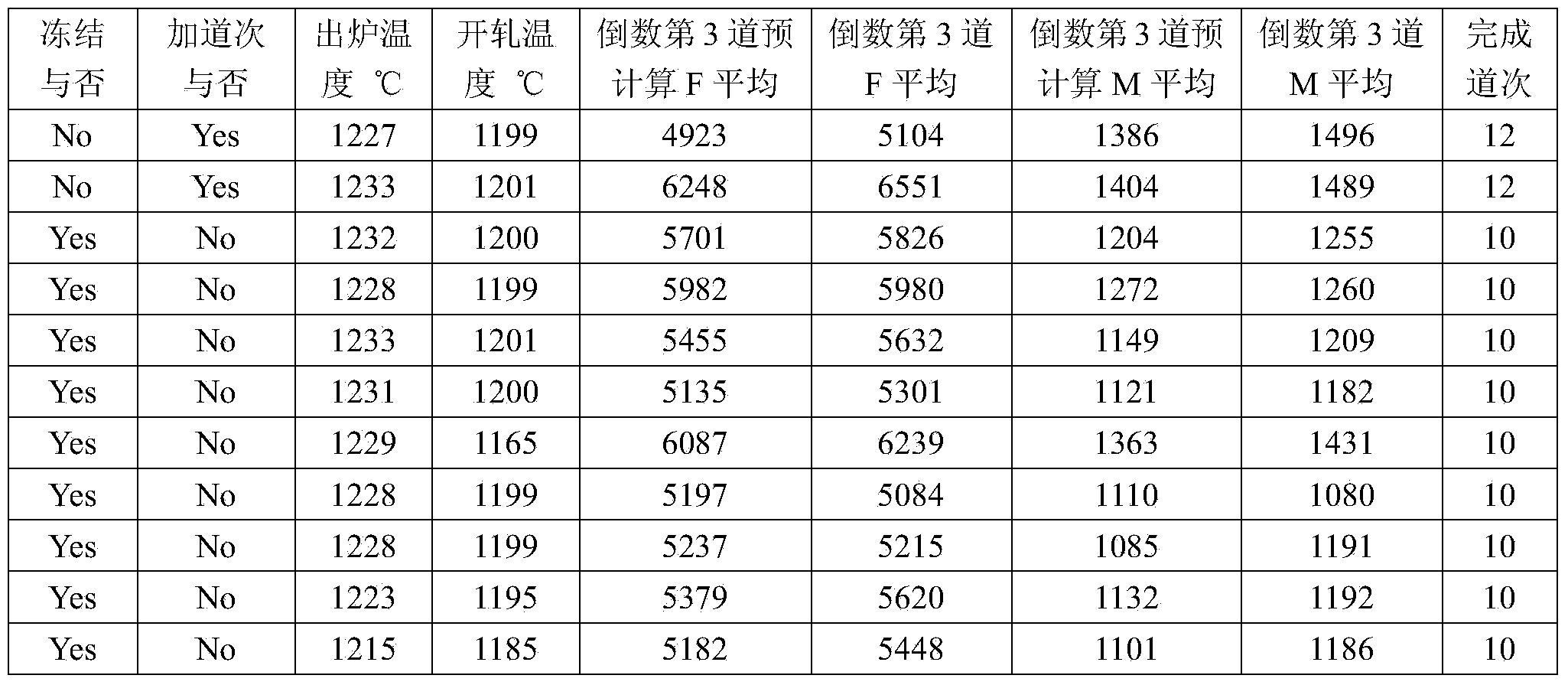

Examples

Embodiment Construction

[0012] The method for freezing the automatic program rolling pass of medium and heavy plates in the present invention is mainly to set a dialog box and input the frozen thickness value according to the best pass rule for rolling a steel billet with a thickness of ≤6.5mm in the past, so that the best pass rule Lock it down. The specific method is:

[0013] Add an effective value of frozen thickness, Frozenthickness, to the parameter Parameters of the Opeyator inputs function of the input terminal of the operation item in the secondary screen of the rolling mill;

[0014] If the thickness of the steel plate being rolled is less than the entered frozen thickness value, the total number of remaining passes of the steel plate will no longer change, but there are still pass calculations;

[0015] If there is an addition or subtraction pass change before the freezing pass, the frozen thickness value is stable at the frozen thickness of multiple passes, that is, "take more but not le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com