Changing device of extrusion container assembly

A technique for extruding cylinders and components, applied in the field of extruding cylinder component replacement devices, which can solve the problems of reduced work efficiency, inconvenient operation, and delay in replacement time, and achieves the effects of simple structure, improved replacement efficiency, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

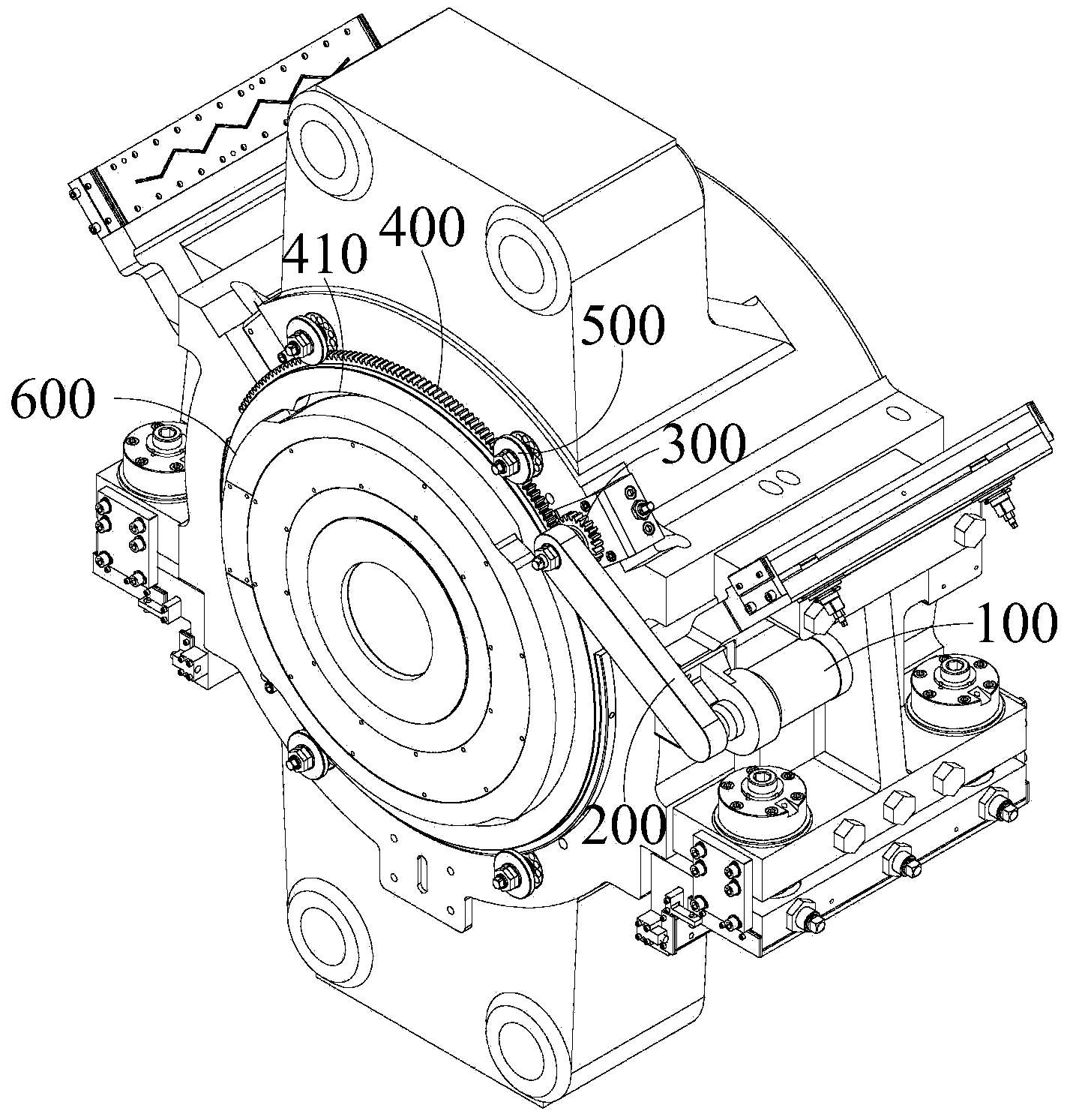

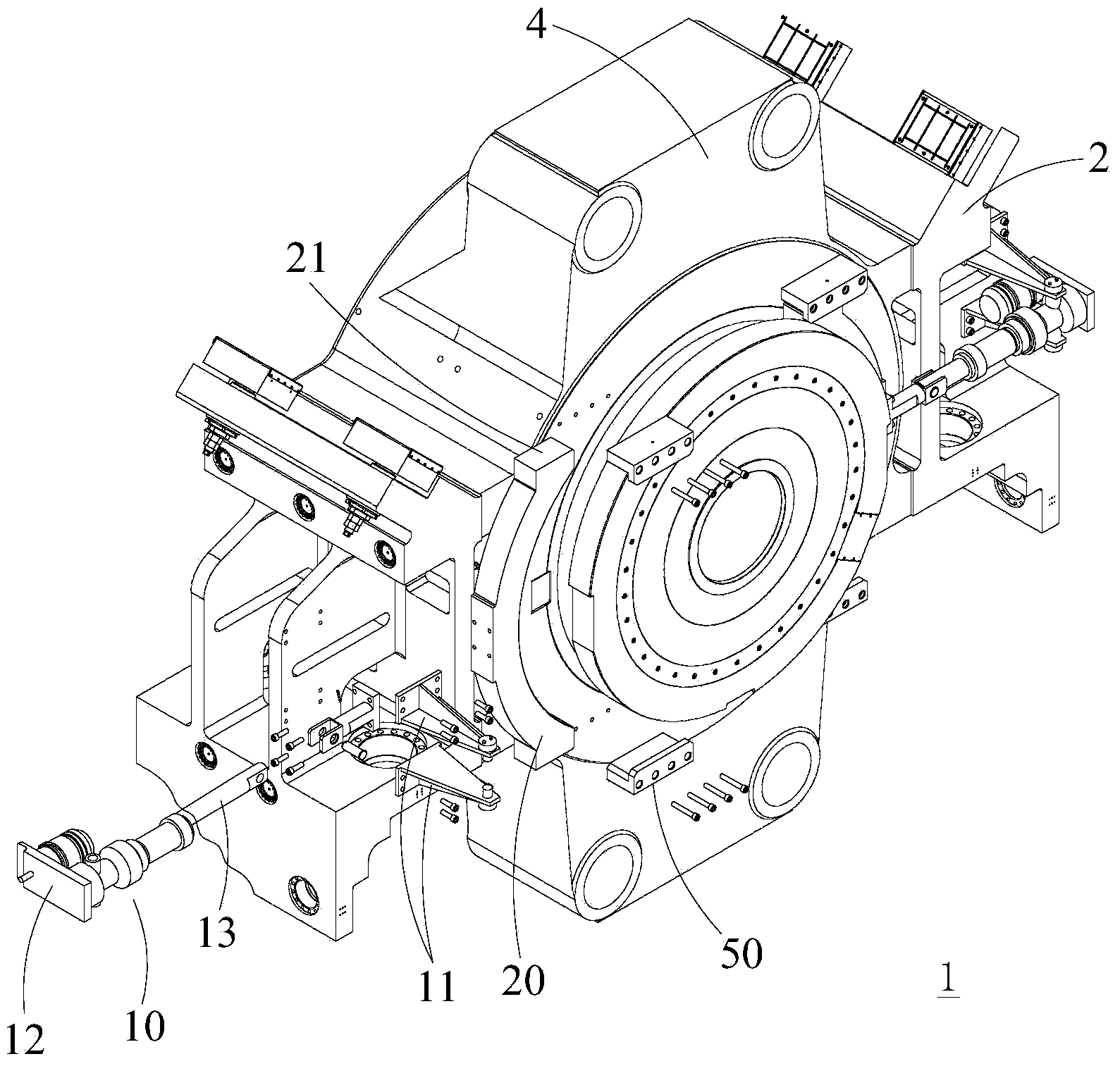

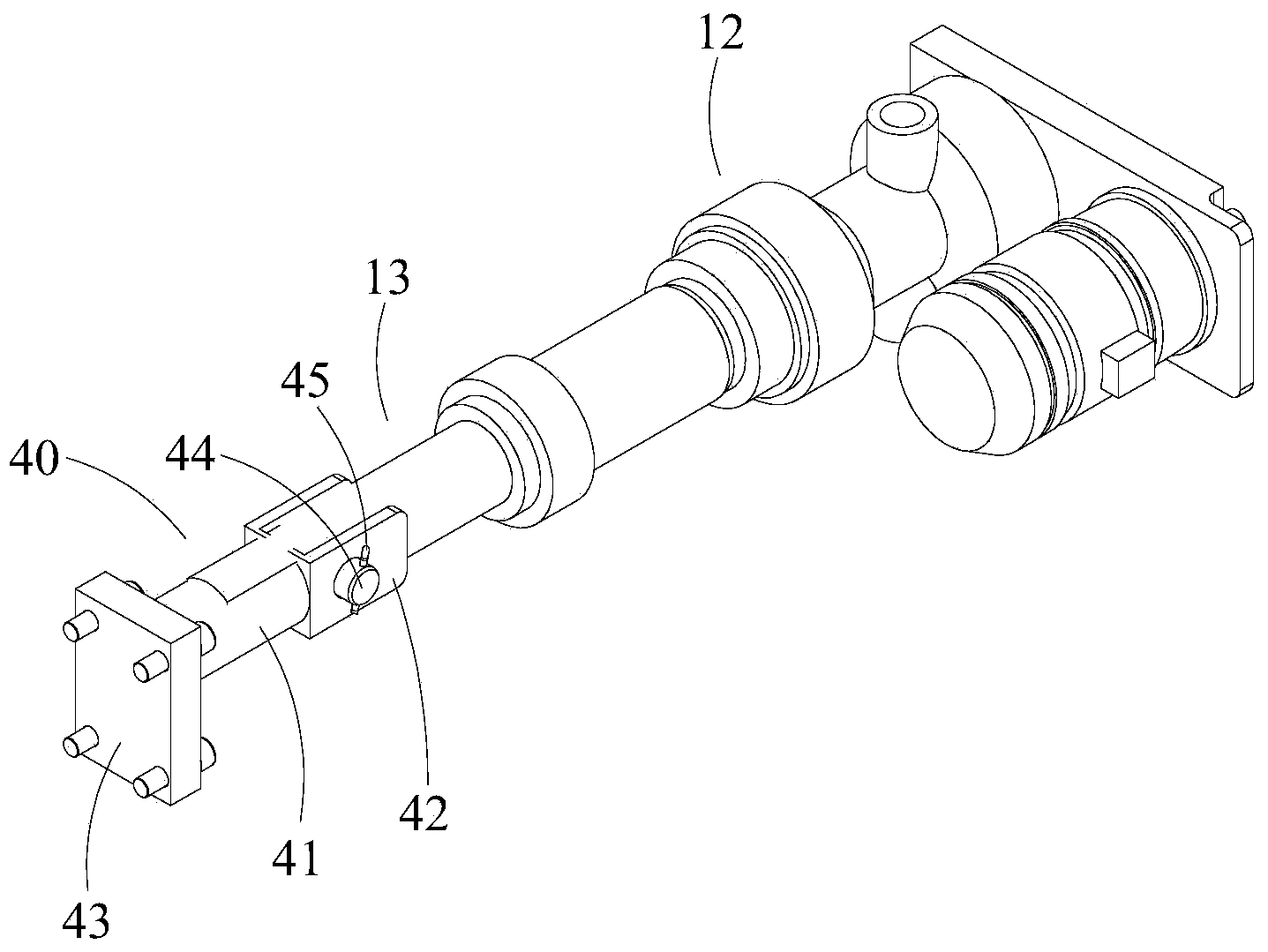

[0016] The present invention provides an extruding cylinder assembly replacement device, which is used to make the extruding cylinder assembly 3 selectively in a locked state or a released state relative to the extruding cylinder device 1, so as to replace the extruding cylinder assembly. Wherein, the extrusion barrel device 1 includes an extrusion barrel assembly 3 , an extrusion barrel shell 4 and an extrusion barrel guide bracket 2 . The extrusion cylinder guide bracket 2 is fixed on both sides of the extrusion cylinder shell 4 , and the extrusion cylinder assembly 3 is clamped in the center of the extrusion cylinder shell 4 during the working process. The e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com