Mechanism suitable for off-line rapid die change of multi-station cold heading machine

A cold heading machine and multi-station technology, applied in the direction of manufacturing tools, metal processing equipment, forging/pressing/hammering machinery, etc., can solve the problems of downtime exceeding processing time, poor precision, cumbersome loading and unloading of molds, etc., and achieve saving Die change time, reduction of die change time, effect of simplifying formwork installation issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with embodiment (accompanying drawing):

[0026] The mechanism of the present invention, which is suitable for off-line rapid mold change of multi-station cold heading machines, includes two parts: a movable mold and a fixed mold.

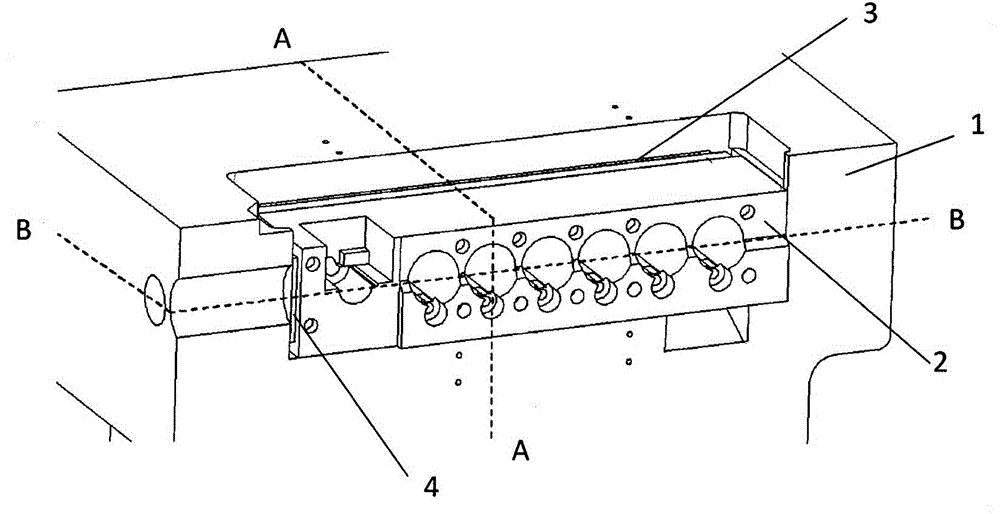

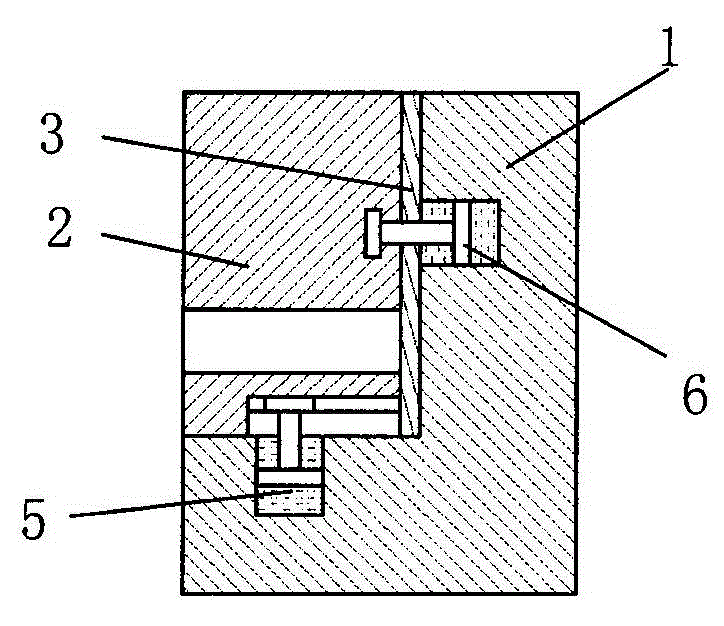

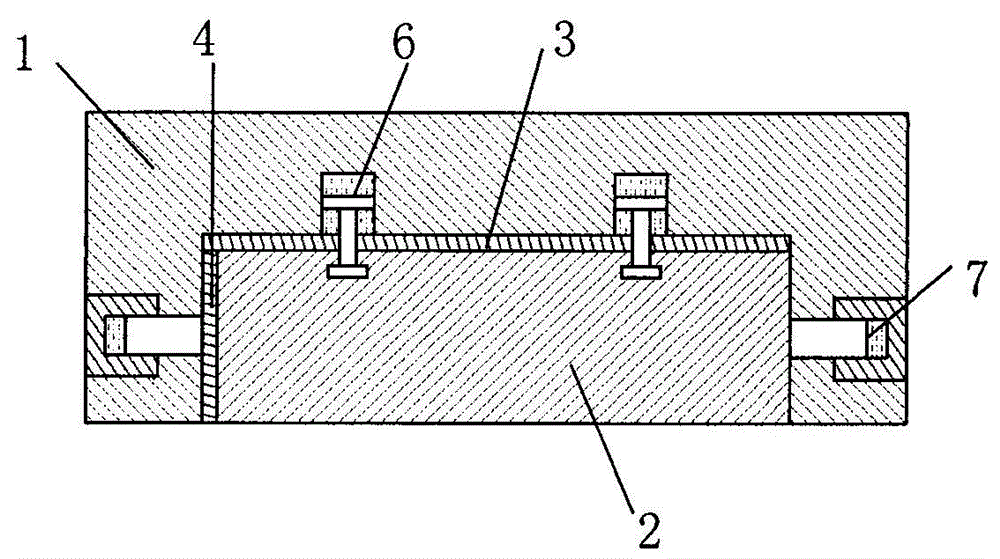

[0027] Such as figure 1 , 2 , 3, the fixed mold part of the present invention includes the fixed mold base 1 of the cold heading machine, and the fixed template block 2 installed in the step-shaped notch provided on one side of the fixed mold base 1 of the cold heading machine. The horizontal hydraulic cylinder 6 of the fixed template for pulling the fixed template block 2 to realize the clamping and positioning of the fixed template block 2 in the horizontal direction is installed between the side elevations of the mold base 1 and the fixed template block 2. The vertical hydraulic cylinder 5 of the fixed template for pulling the fixed template block 2 to realize the clam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com