Ink-jet printing system and application thereof

A printing system and inkjet printing technology, applied in printing, sustainable manufacturing/processing, electrical components, etc., can solve the problems of low resolution, insufficient precision, and increased bad film rate of screen printing, and achieve high-precision super Fine printing, the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

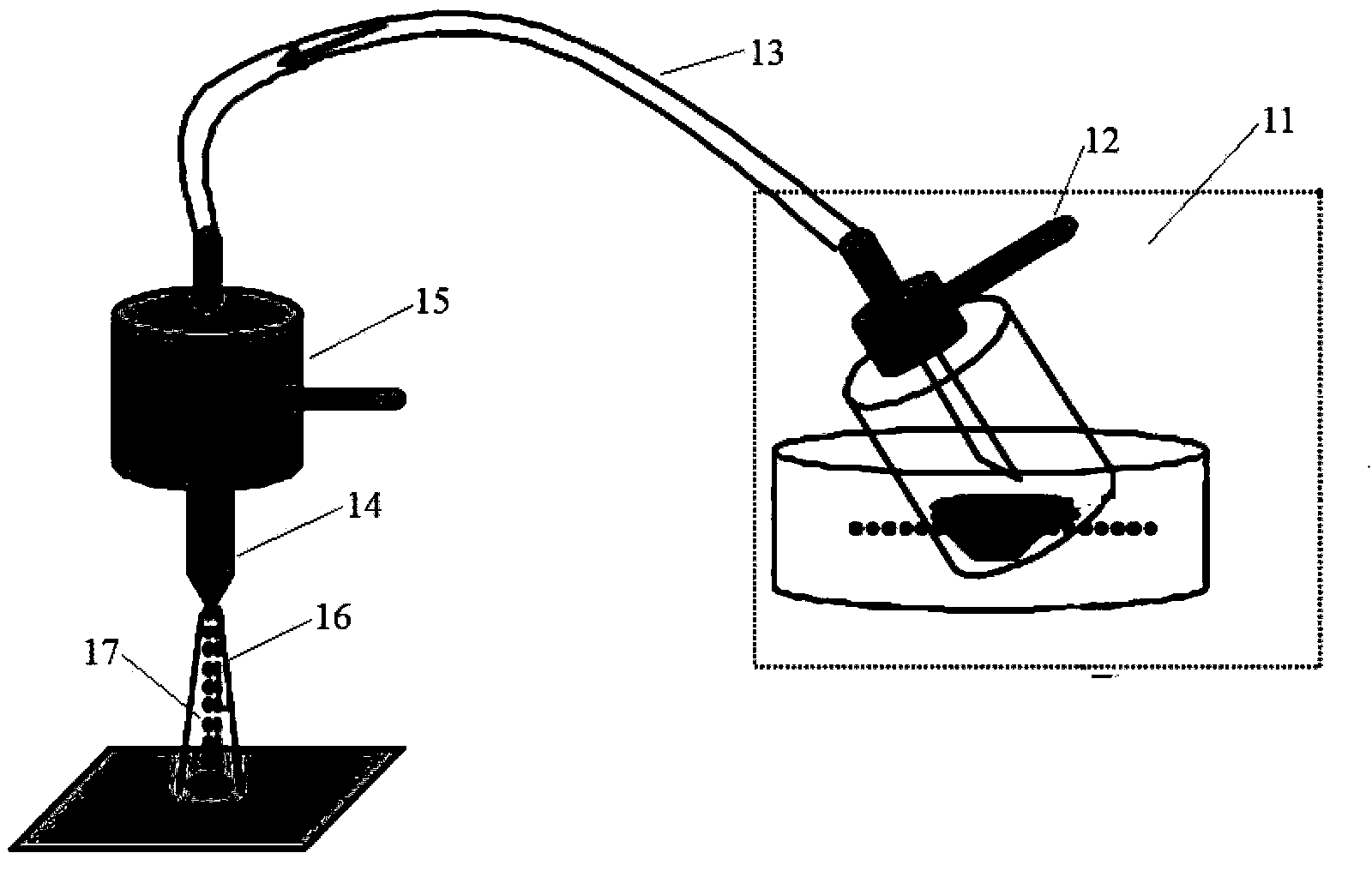

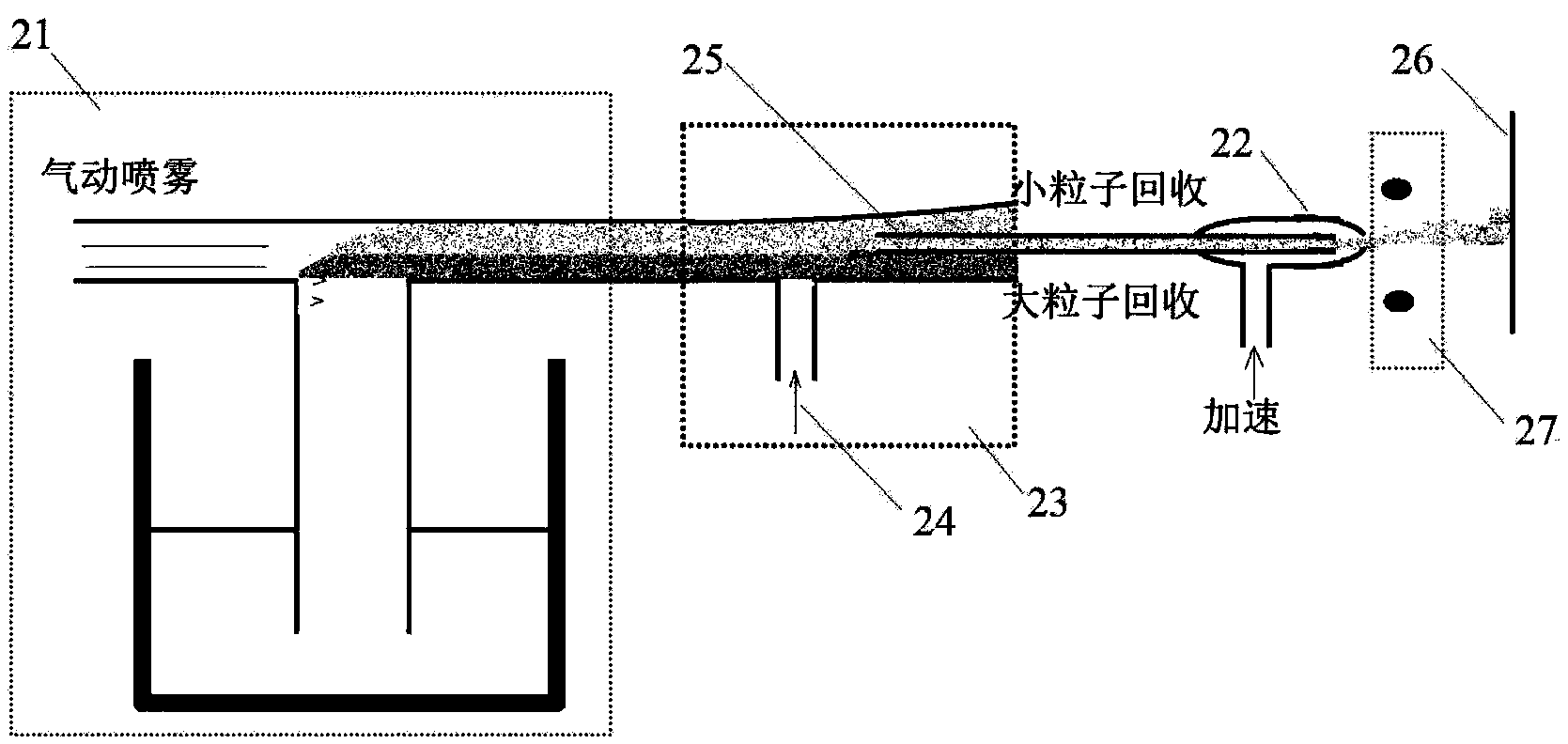

[0033] The inkjet printing system in this example is improved on the basis of the existing aerosol printing system, specifically, as figure 2 As shown, a droplet size screening device is added between the atomization device and the printing nozzle of the original aerosol printer. The droplet size screening device has an input port and two output ports, wherein the input port is connected to the output port of the atomization device The terminal is connected, the first output port is connected to the printing nozzle, and the second output port is connected to the atomizing device. The droplet size screening device includes an airflow injector, the airflow injected by the airflow injector is perpendicular to the airflow direction of the aerosol input from the atomization device into the droplet size screening device, and the trajectory of the droplets in the aerosol is changed by the influence of the vertical airflow , part of the aerosol with a moderate droplet volume enters t...

Embodiment 2

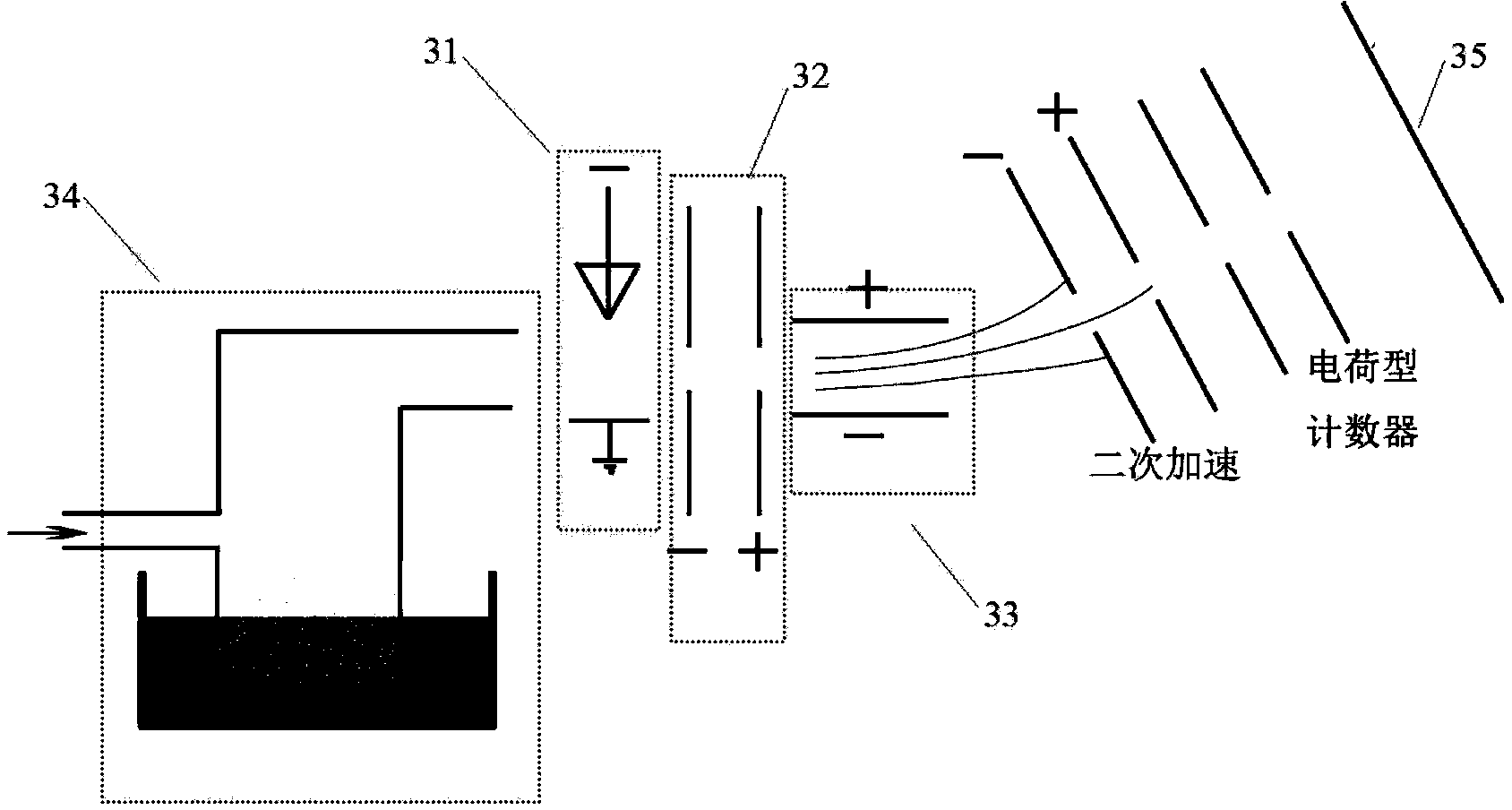

[0036] The inkjet printing system of this example is similar to the inkjet printing system of Embodiment 1, and also adds a droplet size screening device between the atomizing device and the printing nozzle of the original aerosol printer, and the droplet size screening device has an input port and two output ports, wherein the input port is connected to the output end of the atomizing device, the first output port is connected to the printing nozzle, and the second output port is connected back to the atomizing device. The droplet size screening device is composed of an electron emission element, an electrostatic accelerator and a speed filter. The speed filter is composed of two parallel charged metal plates. The electron emission element generates a charged charge to charge the aerosol entering the droplet size screening device. After the charged aerosol is accelerated by the electrostatic accelerator, when it passes through the parallel charged metal plate, under the attrac...

Embodiment 3

[0039] Adopt the inkjet printing system of embodiment 1 or 2, control the printed aerosol to be less than or equal to 10 picoliters, carry out 3D printing to the silver grid line of the front electrode of the solar cell, the cross section of the silver grid line is an isosceles triangle, such as Figure 4 As shown, the base width of the silver grid lines 42 is 50 microns, and the top angle is 55 degrees.

[0040] In the printed solar front electrode, the silver grid wire has a large contact area with the battery and has a low contact resistance; however, if Figure 4 As shown, the light 41 shaded by it can be absorbed after being reflected by the slope, so the shading loss is reduced instead.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com