UV code spraying device of steel tube

A steel pipe and barcode technology, applied in the field of steel pipe UV coding device, can solve problems such as difficult to identify, easy to wear, unable to achieve stable marking and identification of steel pipes, etc., and achieve good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

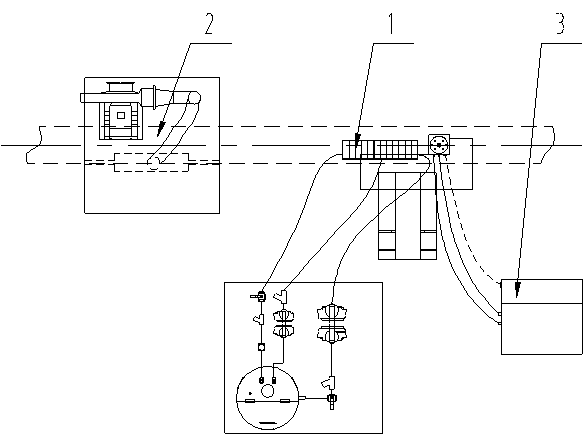

[0025] like figure 1 As shown, the present invention includes a UV barcode printing part 1, a digital printing part 3 and a UV curing part 2; the digital printing part 3, the UV barcode printing part 1, and the UV curing part 2 are respectively installed from right to left In the forward direction of the coded steel pipe. The barcode printing uses UV paint, and uses UV curing part 2 to cure instantly; the content of the logo is a number plus a barcode, which is applied to the online tracking of steel pipes one by one.

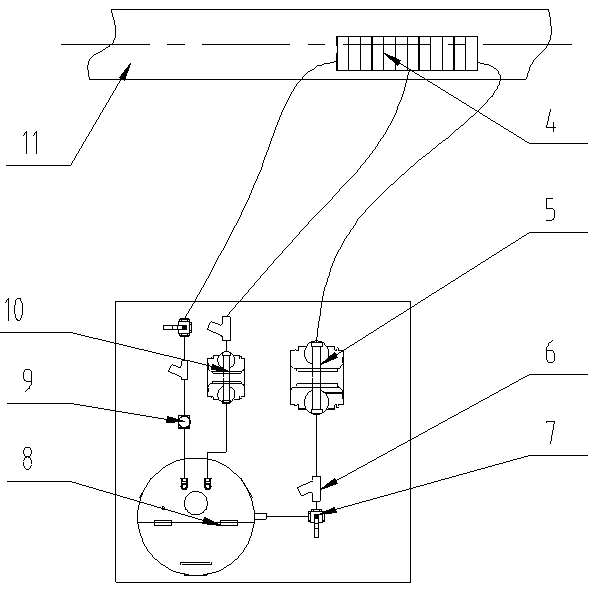

[0026] like Figure 5 As shown, the digital printing part 3 includes a digital nozzle 20, a controller 21 and a pump cabinet 22; the digital nozzle 20 has three circuits, the first circuit is electrically connected to the controller 21, and the other two circuits are connected to the pump cabinet 22. The digital printing part 3 can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com