Self-locking type spray cap

A self-locking, spray cap technology, applied in the direction of liquid distribution, etc., can solve the problems of inconvenient installation and disassembly, inconvenient use, hidden safety hazards, etc., and achieve the effect of beautiful appearance, smooth outer wall and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawing description and specific embodiment:

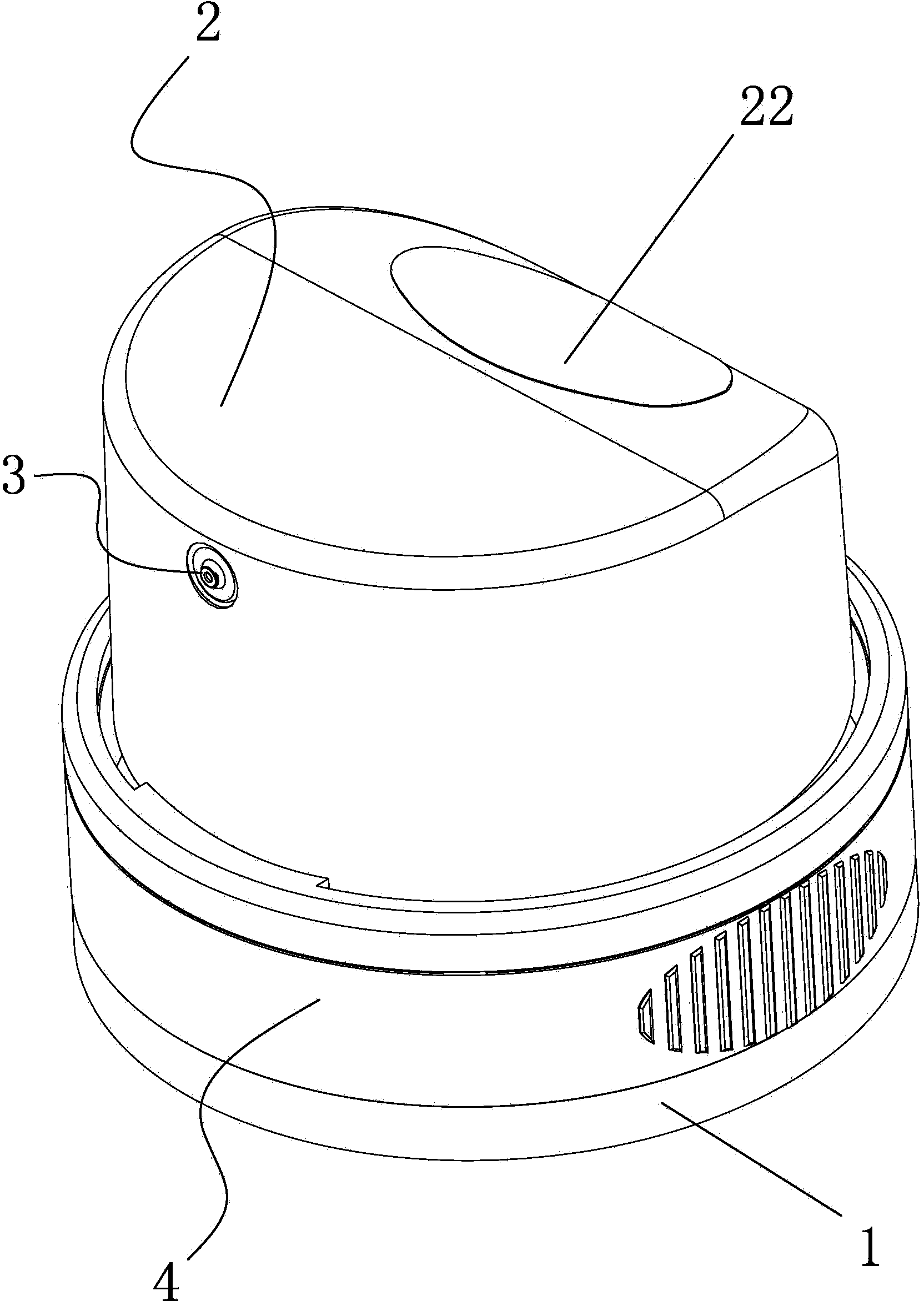

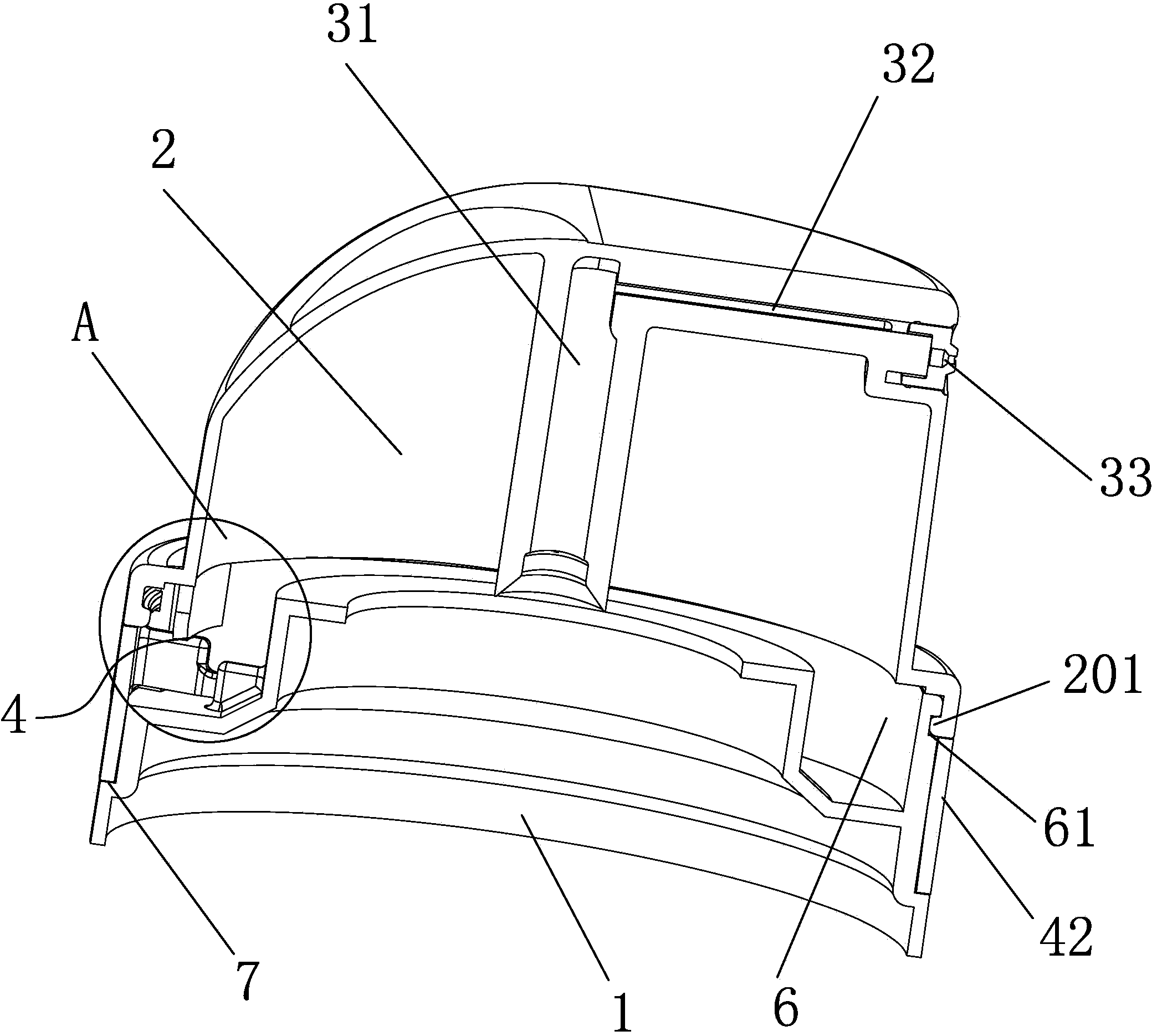

[0030] Such as Figures 1 to 9 The shown self-locking spray cap includes a base 1, a press head 2 is connected to the base 1, a nozzle 3 is provided on the press head 2, and a nozzle 3 is arranged between the base 1 and the press head 2. There is a press head locking mechanism 4 that can prevent the press head 2 from pressing down and moving.

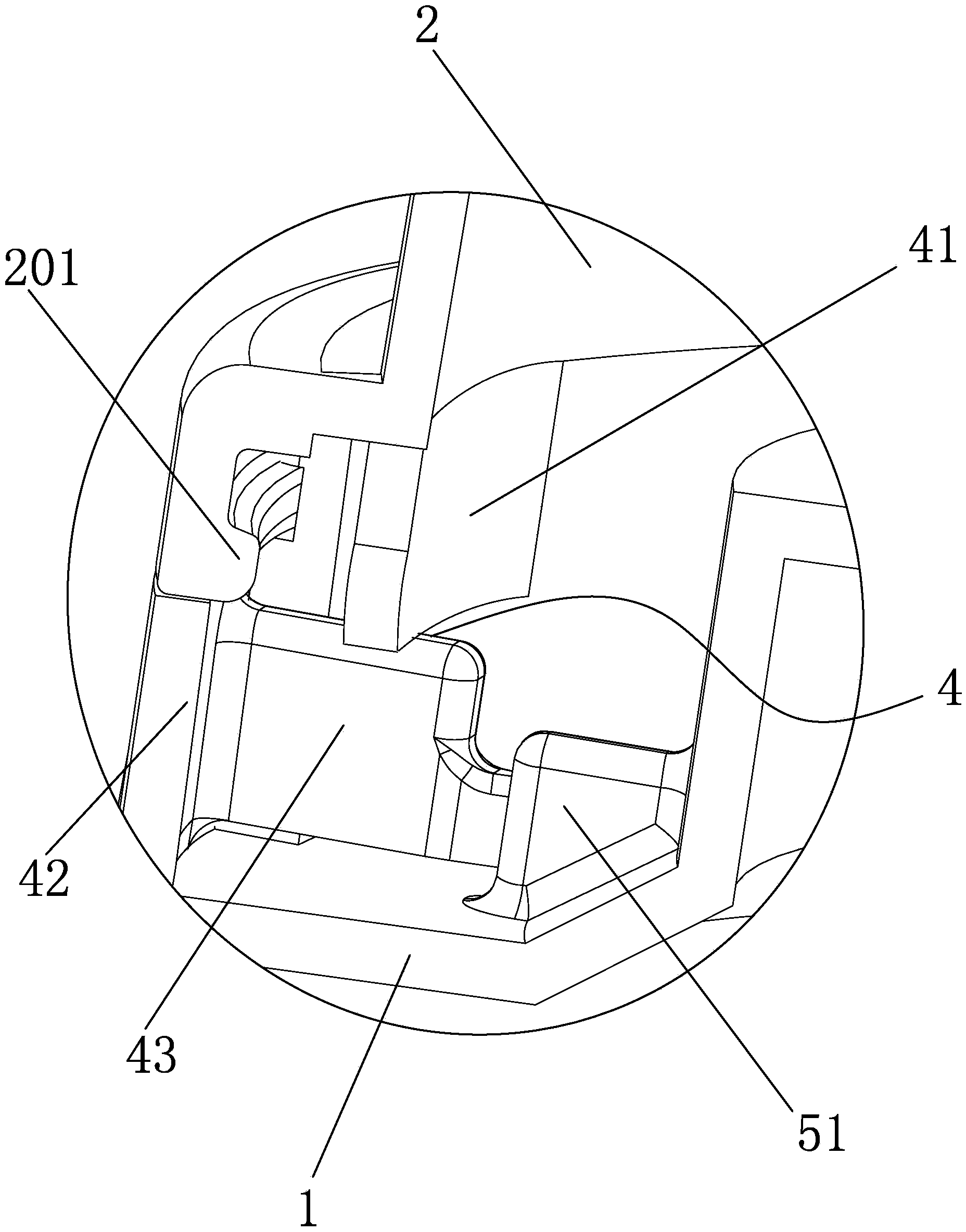

[0031] Such as figure 2 and 3 As shown, the press head locking mechanism 4 in the present invention includes a positioning block 41 extending downward inside the press head 2 , and a lock ring 42 is provided between the press head 2 and the base 1 on the inner wall of the lock ring 42 There is a lock tongue 43 that can be pressed against the lower end of the positioning block 41 so as to prevent the press head 2 from moving downwards. The base 1 is provided with a limiting groove 44. Inside sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com