Beer fermentation tank

A beer fermentation and tank technology, which is applied in beer fermentation methods, beer brewing, biochemical equipment and methods, etc., can solve the problems of inability to meet production requirements, slow cooling speed, and small heat exchange area in the jacket space. The effect of meeting production needs, fast cooling speed and high heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

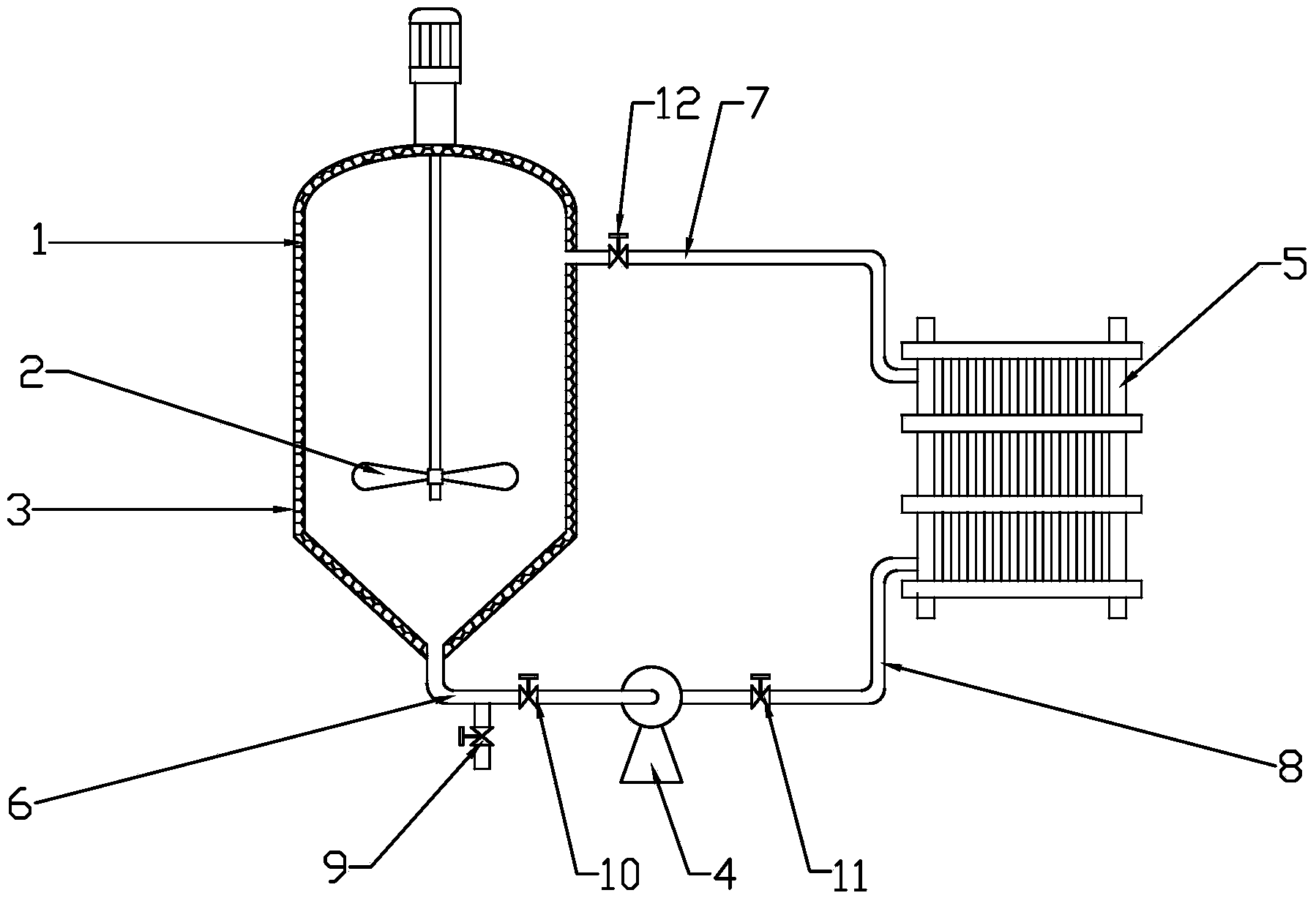

[0009] Refer to the attached figure 1 The beer fermenter of the present invention will be described in detail below.

[0010] A kind of beer fermentation tank of the present invention, it comprises tank body 1, and agitator 2 is arranged in tank body, and insulation layer 3 is arranged outside tank body, and described fermentation tank also comprises circulation pump 4 and plate heat exchanger 5, and described tank The bottom of the tank body 1 is connected to the circulation pump 4 through the liquid outlet pipeline 6, the upper part of the tank body 1 is connected to the plate heat exchanger 5 through the circulation pipeline 7, and the circulation pump 4 is connected to the plate heat exchanger 5 through the middle pipeline 8, so that The bottom of the tank body 1 has a liquid outlet valve 9, the circulation pump 4 has a front valve 10 and a pump rear valve 11 respectively, and the circulation pipeline 7 has a liquid inlet valve 12.

[0011] When cooling is required, open ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com