Electrolytic manganese cathode plate leveling and polishing machine

A cathode plate and polishing machine technology, applied in the electrolysis process, electrolysis components, etc., can solve low-level problems, achieve the effects of saving enterprise resources, prolonging the service life, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

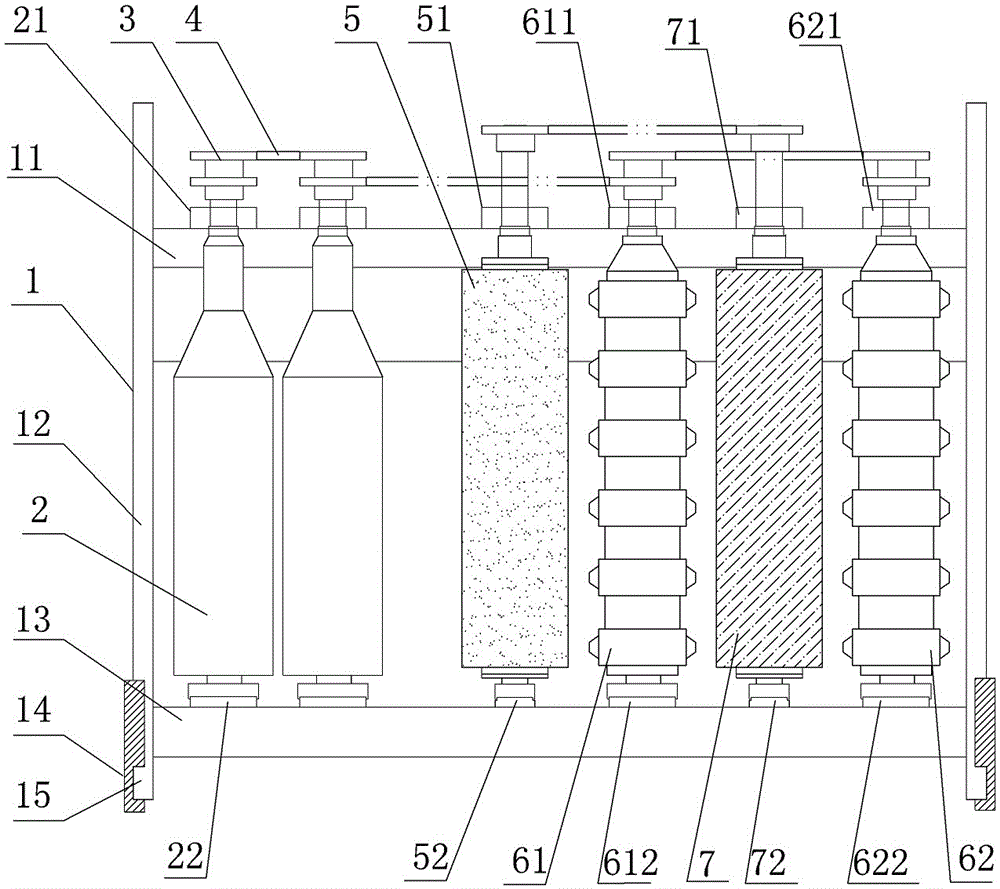

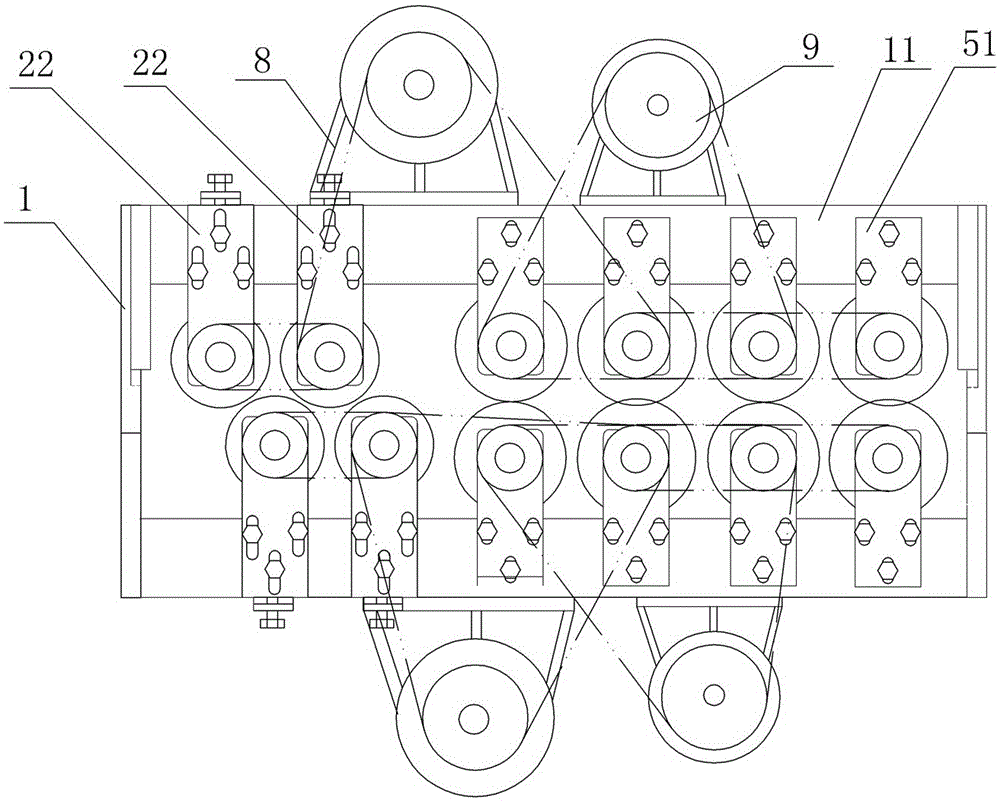

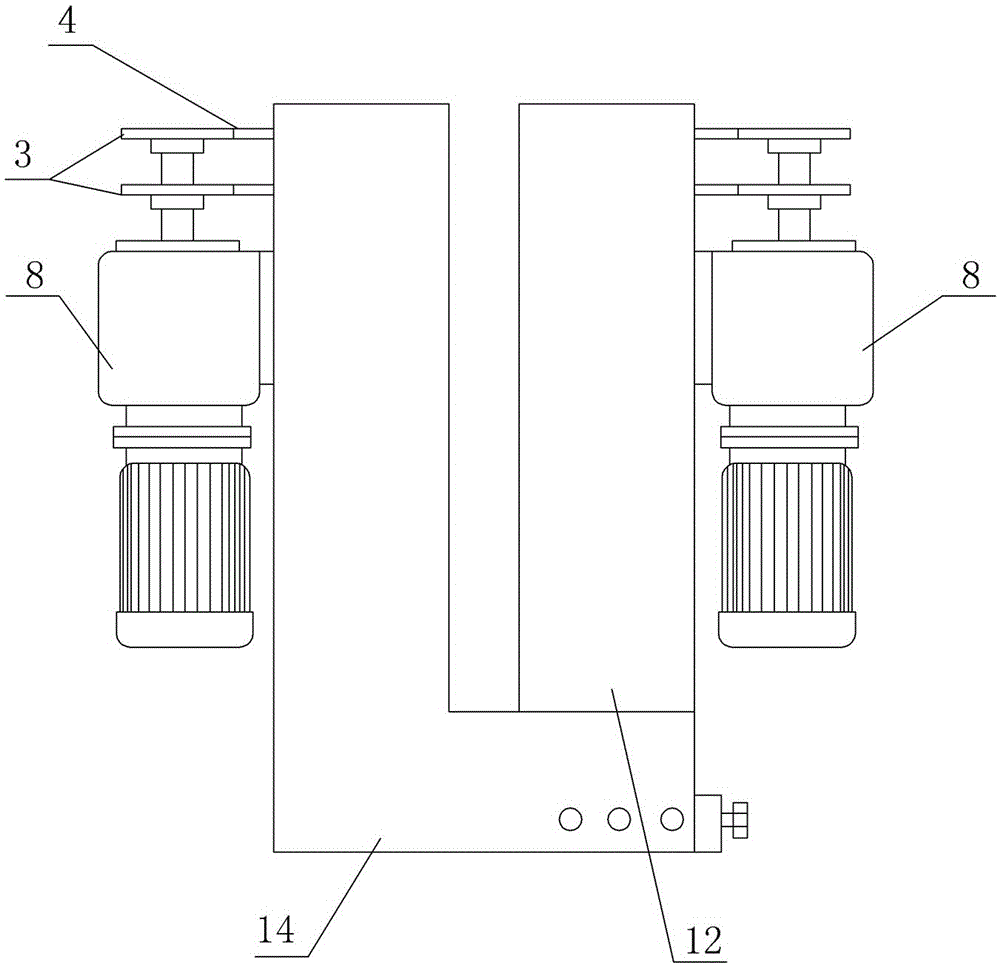

[0028] Embodiment 1, the present invention comprises frame part, leveling part and polishing part; Described frame part is the frame 1 that is formed by plate welding, and it comprises a pair of L-shaped main board 14, and main board 14 connects main board 15 through slideway 15 Skateboards 12 are movably connected, between two main boards 14 and between two main slides 12 are respectively fixed and positioned by upper beam 11 and lower beam 13, upper beam 11 is provided with upper bearing seat I21 and upper bearing seat with grooved bolt holes Ⅱ51, the lower beam 13 is provided with the lower bearing seat I22 and the lower bearing seat II52 with grooved bolt holes; the leveling part includes more than 2 pairs of steel wheels 2 arranged in the shape of a character, and the working height of the steel wheels 2 It is 3 / 5-4 / 5 of the height of the cathode plate, and the upper part of the steel wheel 2 is conical; the two ends of each steel wheel 2 are movably connected to the upper...

Embodiment 2

[0029] Embodiment 2, the frame part is a frame body 10 welded with profiles, and the frame body 10 includes four columns 102, and a plurality of upper main beams 101, lower main beams 103, upper beams 104 and Lower beam 105. refer to Figure 1 to Figure 7 , all the other are with embodiment 1.

Embodiment 3

[0030] Embodiment 3, described steel wheel 2, steel wire wheel 5, conveying wheel I61, conveying wheel II62 and the transmission shaft of cloth wheel 7 tops are equipped with sprocket wheel 3, all steel wheels 2 and all conveying wheels I61, all on the same side of frame 1 The conveying wheel II62 is connected to the motor I8 on the same side through the chain 4, the steel wire wheel 5 and the cloth wheel 7 on the same side of the frame 1 are connected to the motor II9 on the same side through the chain 4, and the power output shaft of the motor I8 and the motor II9 is equipped with a sprocket 3. refer to Figures 1 to 7 , and the rest are the same as the above-mentioned embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com