Steel stranded wire anchor gear installing device and anchor gear seat of steel stranded wire anchor gear installing device

A technology for installation devices and anchorage seats, which is applied in construction, sheet pile walls, foundation structure engineering, etc., can solve the problems of non-reusable use, low support rigidity, and difficulty in controlling deformation, so as to save construction costs and increase construction space , The effect of convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

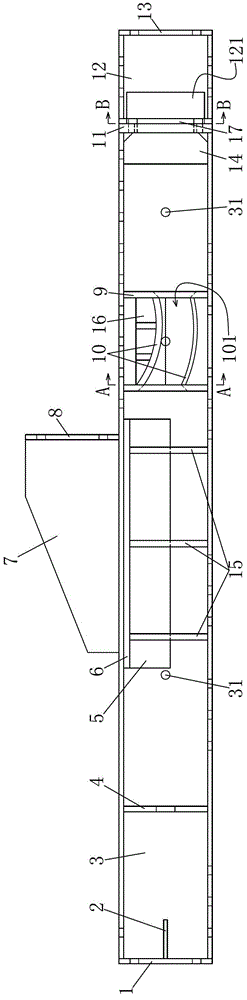

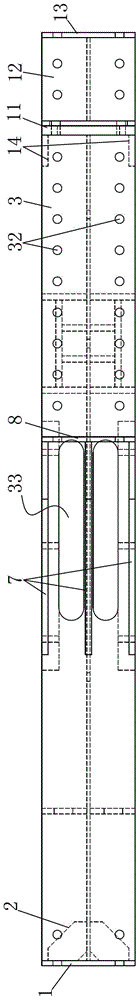

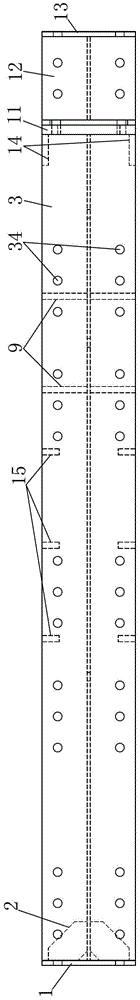

[0023] Such as figure 1 The steel strand anchorage installation device of the internal support system of foundation pit support shown includes the anchorage seat and connecting parts.

[0024] The anchorage seat includes H-shaped steel A3, the left end surface of H-shaped steel A3 is a cross-section and is welded and fixed with a connecting flange A1, and the right end surface of H-shaped steel A3 is a cross-section and is welded and fixed with an anchor substrate 11, such as Figure 7 As shown, the center of the anchor substrate 11 is provided with an anchor installation hole 112 for installing the anchor, and four bolt holes A111 are arranged around the anchor installation hole 112; figure 1 , figure 2 As shown, two threading long holes 33, three baffles 7 and a connecting flange B8 are provided on the front side panel of the H-shaped steel A3, and the two threaded long holes 33 are located side by side on both sides of the web of the H-shaped steel A3. Three baffles 7 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com