Connecting piece of plastic template

A technology of plastic templates and connectors, which is applied to the connectors of formwork/formwork/work frame, the preparation of building components on site, construction, etc., which can solve the problems of not being able to spell geometric figures, serious environmental pollution, and low work efficiency. , to achieve the effect of easy grasp and application, strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

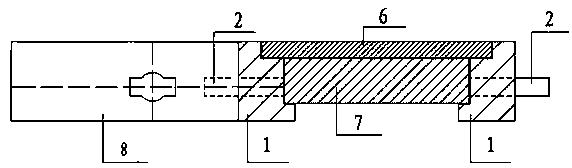

[0013] The present invention will be further described below in conjunction with accompanying drawing.

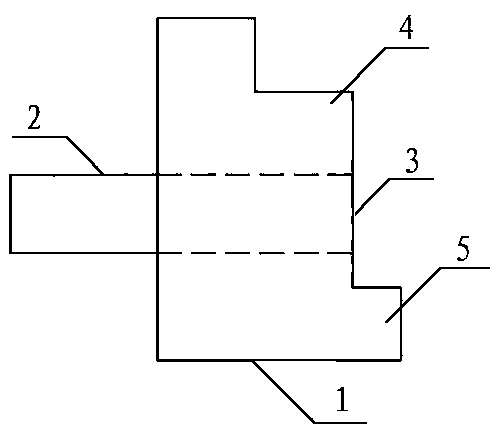

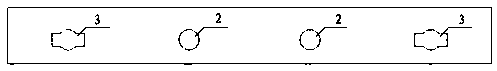

[0014] Such as figure 1 As shown, a connector for a plastic formwork includes a board body 1, the board body 1 is provided with an L-shaped corner 5, and two pin shafts 2 are provided on the side of the board body 1, between the two pin shafts 2 There are pin holes 3 between them.

[0015] As a further improvement, the plate body 1 is also provided with an L-shaped tongue and groove 4, the opening is outward, and the cross section of the plate body 1 is stepped.

[0016] Further, the length of the pin shaft 2 of the plate body 1 is consistent with the plastic template, the diameter of the pin shaft 2 is consistent with the inner diameter of the pin hole of the template, and the center distance of the pin shaft is consistent with the distance between the pin holes of the template.

[0017] Further, the shape, size, and center distance of the pin holes 3 of the plate body 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com