Core shaft type sealed oil pipe shoes

A mandrel and tubing technology, used in sealing/packaging, wellbore/well components, earth-moving drilling, etc., can solve the problems that the test instrument cannot pass through the check valve, obstruction, falling objects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

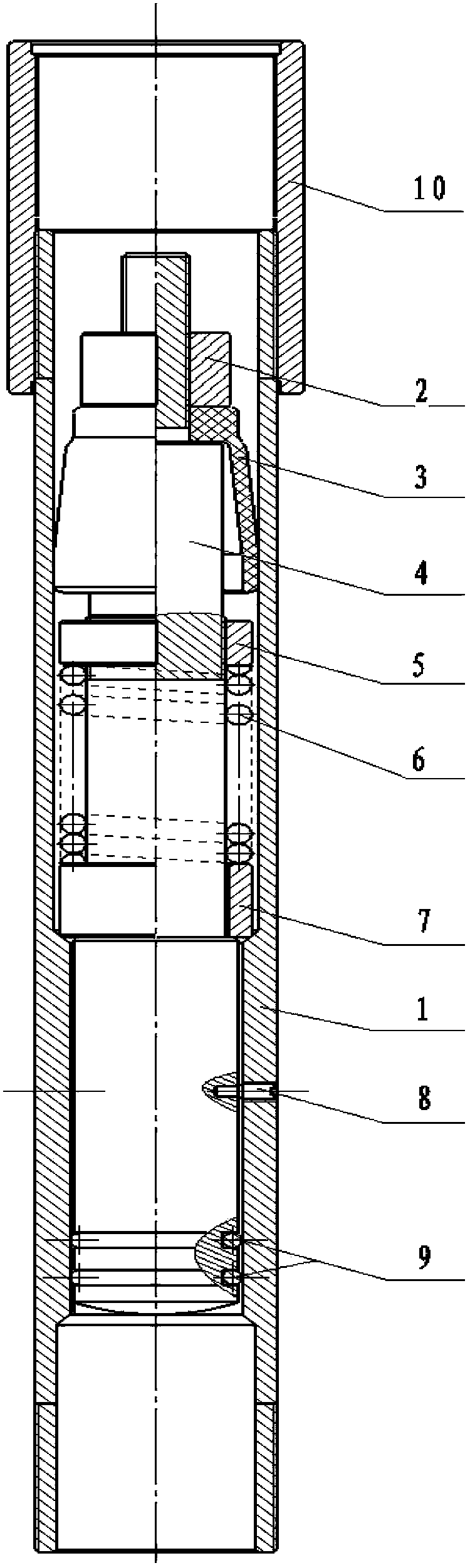

[0010] Such as figure 1 As shown, the mandrel type airtight tubing shoe of the present invention is made up of working cylinder 1 and mandrel body, and mandrel body is made of leather cup pressing cap 2, leather cup 3, mandrel 4, spring pressing cap 5, return spring 6, mandrel The mandrel body is fixed inside the working cylinder 1 through the shear pin 8, the mandrel body is sealed with the working cylinder 1 through the sealing rubber ring 9, and the device is connected through the upper joint 10 When the lower end of the tubing is run into the well, the well pressure and the impact force generated during running the string are much smaller than the shear value set by the shear pin 8, so the shear pin 8 cannot be cut off to realize the plugging function in the string. The shearing pin 8 can choose pins of different diameters according to well pressure conditions to meet the needs of different pressure conditions. During the running of the pipe string, fill the pipe string w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com